In dental furnace operations, the preheat and cooldown phases are non-negotiable steps for preventing catastrophic failure of ceramic restorations. Rushing or skipping them induces thermal shock—a rapid, uneven temperature change that causes the material to crack internally. These controlled phases ensure the structural integrity, longevity, and clinical success of the final appliance.

Rushing preheat or cooldown saves minutes but risks hours of rework and the material cost of a failed restoration. These phases are not optional shortcuts; they are fundamental to managing internal stress in brittle ceramic materials.

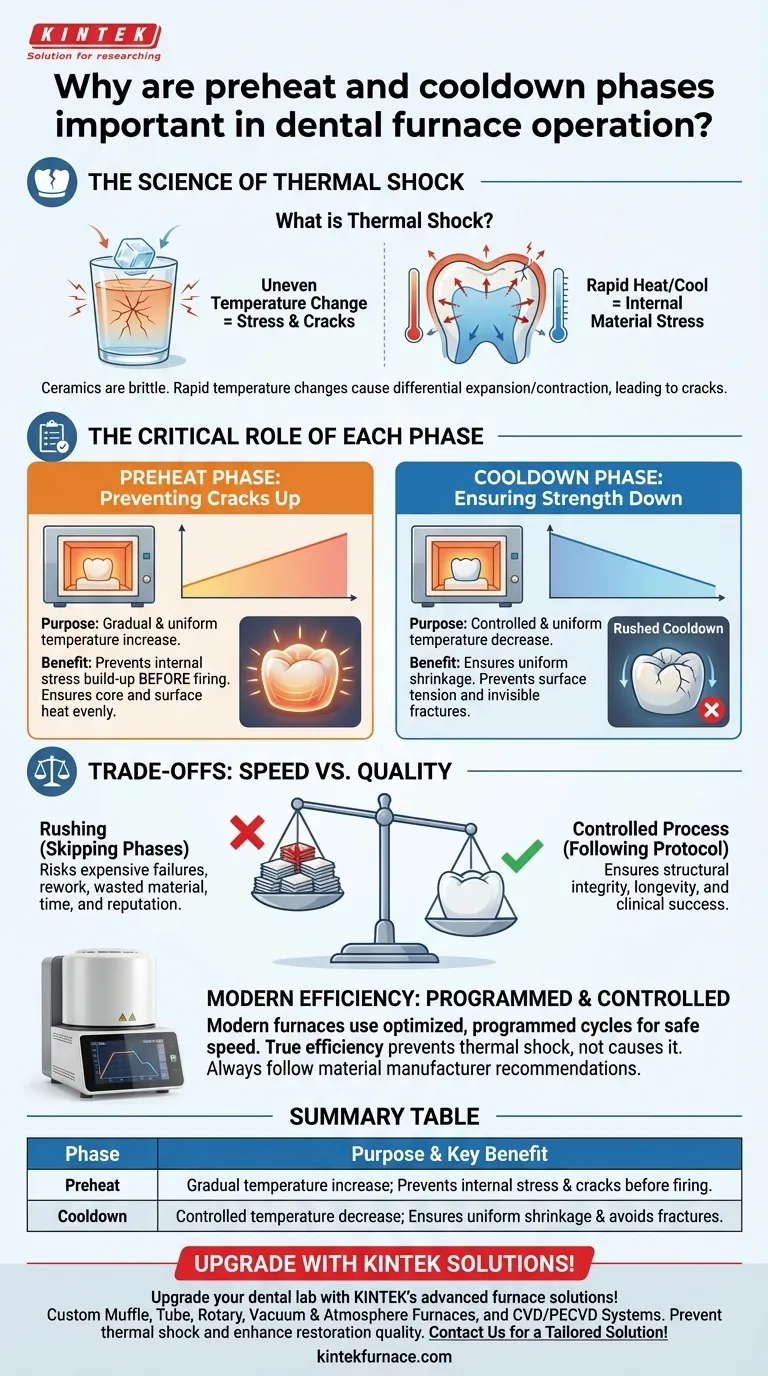

The Science of Thermal Shock in Dental Restorations

To understand the importance of these phases, we must first understand the force they are designed to prevent: thermal shock.

What is Thermal Shock?

Thermal shock occurs when a material experiences a rapid change in temperature, causing different parts of the object to expand or contract at different rates.

This creates immense internal stress. In brittle materials like dental ceramics, this stress is relieved by the formation of cracks.

The Analogy of Ice in a Warm Drink

Imagine dropping an ice cube into a glass of warm water. You often hear an immediate crackling sound as the ice fractures.

The outer surface of the ice heats up and expands instantly, while the cold interior does not. This differential is what causes the ice to crack—the same principle applies to a zirconia crown being heated or cooled too quickly.

Why Ceramics are So Vulnerable

Materials like zirconia and lithium disilicate are exceptionally strong under compression but are brittle and have poor thermal conductivity.

When heated or cooled rapidly, the heat doesn't transfer through the material evenly. The surface changes temperature much faster than the core, building up stress that has nowhere to go but to initiate a fracture.

The Critical Role of Each Phase

Each phase has a distinct purpose in stabilizing the restoration before and after the critical high-temperature firing cycle.

The Preheat Phase: Preventing Cracks on the Way Up

The preheat phase gradually and uniformly raises the temperature of the entire restoration, from its core to its surface.

This slow, controlled ramp-up ensures no significant temperature difference develops within the material. This prevents stress from building before the main sintering or glazing process even begins, where the material is most vulnerable.

The Cooldown Phase: Ensuring Strength on the Way Down

The cooldown phase is arguably even more critical. As the furnace cools, the restoration must shrink uniformly.

Opening the furnace door too soon or forcing a rapid cool-down causes the outer surface to shrink quickly while the core remains hot and expanded. This tension pulls the surface apart, leading to fractures that may not even be visible until after cementation.

Modern furnaces with efficient cooling systems manage this process precisely. They reduce cycle times not by shocking the material with cold air, but by orchestrating a controlled, accelerated temperature drop that respects the material's physical limits.

Understanding the Trade-offs: Speed vs. Quality

In a busy lab or clinic, the temptation to shorten furnace cycles is understandable. However, this is almost always a false economy.

The Hidden Cost of Rushing

Saving 20 or 30 minutes on a cooling cycle seems efficient until a crown cracks.

A single failure negates any time saved. It requires a complete remake, wasting hours of technician time, valuable material, and potentially delaying patient treatment and damaging your professional reputation.

When Speed Can Be Achieved Safely

True efficiency is not about uncontrolled speed; it's about predictable and reliable processes.

Modern, programmable furnaces can safely shorten cycles by optimizing the heat-up and cool-down curves specifically for the material being used. The key is that the speed is programmed and controlled, preventing thermal shock rather than causing it. Always follow the specific cycle recommendations from both the furnace and material manufacturer.

Making the Right Choice for Your Goal

Your furnace protocol should align directly with your primary objective.

- If your primary focus is material integrity and avoiding remakes: Strictly adhere to the manufacturer-recommended preheat and cooldown cycles for the specific material you are using.

- If your primary focus is optimizing workflow efficiency: Invest in a modern furnace with a programmable, actively controlled cooling system that can safely shorten cycle times.

- If you are troubleshooting frequent cracks or failures: Immediately audit your furnace protocols, as rushed preheat and cooldown phases are the most common culprits.

Mastering these furnace phases is the key to transforming material potential into predictable, high-quality clinical outcomes.

Summary Table:

| Phase | Purpose | Key Benefit |

|---|---|---|

| Preheat | Gradual temperature increase | Prevents internal stress and cracks before firing |

| Cooldown | Controlled temperature decrease | Ensures uniform shrinkage and avoids fractures |

Upgrade your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique needs. Prevent thermal shock and enhance restoration quality—contact us today for a tailored solution!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations