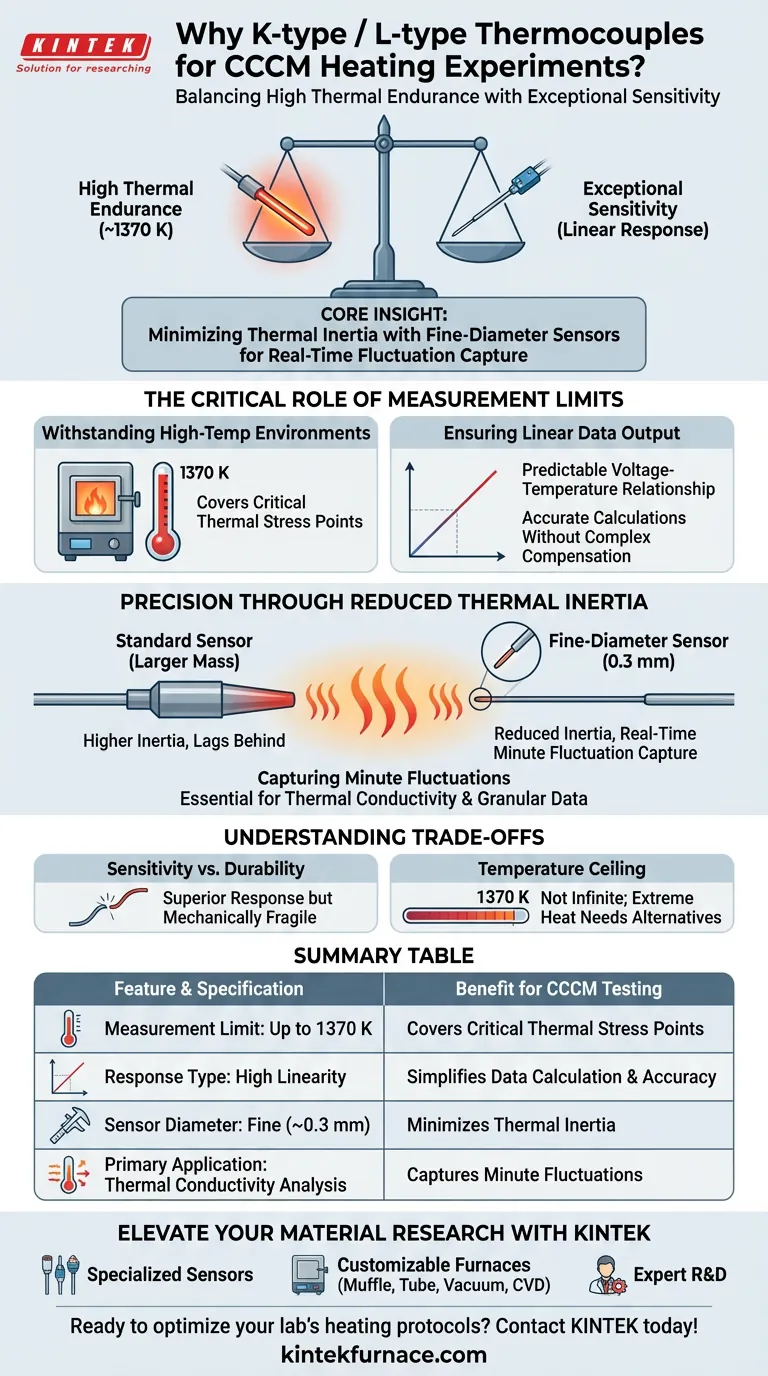

K-type (chromel-alumel) and L-type thermocouples are selected for Carbon-Carbon Composite Material (CCCM) experiments because they uniquely balance high thermal endurance with exceptional sensitivity. They provide a high measurement ceiling of approximately 1370 K while delivering the linear response required to accurately calculate thermal conductivity.

Core Insight: The selection of these thermocouples is not just about withstanding heat; it is about minimizing thermal inertia. By using fine-diameter sensors within this specific temperature range, researchers can capture the minute, real-time fluctuations necessary to characterize the material's internal thermal properties.

The Critical Role of Measurement Limits

Withstanding High-Temperature Environments

CCCM experiments often involve extreme heating conditions to test material resilience.

K-type and L-type thermocouples are utilized because they offer a high measurement limit of approximately 1370 K.

This range covers the critical thermal stress points required for most standard carbon composite testing protocols.

Ensuring Linear Data Output

Reliable data interpretation depends on a predictable relationship between voltage and temperature.

These thermocouples provide excellent linear response characteristics across their operating range.

This linearity ensures that the data remains accurate as temperatures rise, allowing researchers to track predefined thermal curves without complex compensation algorithms.

Precision Through Reduced Thermal Inertia

The Advantage of Fine Diameters

To maximize precision, these experiments often utilize thermocouples with a very fine diameter, typically around 0.3 mm.

The physical mass of the sensor significantly impacts its reaction speed.

A smaller diameter drastically reduces the thermal inertia of the sensor, meaning the sensor itself does not absorb significant heat or lag behind the actual environment temperature.

Capturing Minute Fluctuations

In CCCM analysis, calculating thermal conductivity requires detecting very subtle changes in heat transfer.

Reduced thermal inertia allows for the real-time capture of minute temperature fluctuations.

This level of sensitivity is essential for monitoring both the specimen surface and the interior core, providing the granular data needed for accurate thermal property calculations.

Understanding the Trade-offs

Sensitivity vs. Durability

While fine-diameter (0.3 mm) thermocouples provide superior response times, they are mechanically more fragile than standard industrial probes.

In rigorous testing environments, care must be taken to ensure the wire integrity is not compromised by physical stress or debris.

Temperature Ceilings

While 1370 K is sufficient for many CCCM experiments, it is not an infinite limit.

If an experiment pushes beyond this specific threshold into ultra-high temperature regimes, K-type sensors may degrade, requiring alternative non-contact measurement methods or tungsten-rhenium thermocouples.

Making the Right Choice for Your Goal

When configuring your CCCM experiment, select your sensor geometry based on your specific analytical needs:

- If your primary focus is Thermal Conductivity Calculations: Prioritize fine-diameter (0.3 mm) thermocouples to minimize thermal inertia and capture rapid, minute internal fluctuations.

- If your primary focus is General Furnace Monitoring: Ensure your thermocouples are integrated with high-temperature sealants to maintain airtightness and pressure balance, ensuring the accuracy of heat loss data.

Select the sensor that offers the highest fidelity for your specific data requirements, not just the highest temperature rating.

Summary Table:

| Feature | K-Type / L-Type Specification | Benefit for CCCM Testing |

|---|---|---|

| Measurement Limit | Up to 1370 K | Covers critical thermal stress points |

| Response Type | High Linearity | Simplifies data calculation and accuracy |

| Sensor Diameter | Fine (approx. 0.3 mm) | Minimizes thermal inertia for real-time tracking |

| Primary Application | Thermal Conductivity Analysis | Captures minute fluctuations in heat transfer |

Elevate Your Material Research with KINTEK

Precision in CCCM testing requires more than just high temperatures—it demands expert control and reliable data. KINTEK provides high-performance laboratory solutions, from specialized sensors to fully customizable Muffle, Tube, Vacuum, and CVD systems. Our expert R&D and manufacturing teams ensure every furnace is optimized for your unique thermal property calculations.

Ready to optimize your lab’s heating protocols? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Dmytro Borovyk, D.I. Skliarenko. DETERMINATION OF THERMOPHYSICAL CHARACTERISTICS OF CARBON-CARBON MATERIALS BY A COMPUTATIONAL-EXPERIMENTAL METHOD. DOI: 10.31472/ttpe.4.2024.4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the two types of silicon carbide heating elements described? Compare One-Piece vs. Three-Piece for Your Lab

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are high-temperature heating elements made of? Choose the Right Material for Your Furnace

- How do in-situ heaters and precision current sources cooperate to stabilize the SkBL in NdMn2Ge2?

- What types of silicon carbide heating elements are available? Choose the Right Shape for Your High-Temp Needs

- Why is a ceramic substrate with an integrated heating device necessary for GaS ammonia sensors? Ensure Precise Testing

- What are the properties and applications of Molybdenum (Mo) in heating elements? Choose the Right Element for High-Temp Success

- Why is a low expansion coefficient beneficial for graphite heating elements? Achieve Superior Thermal Stability