High-precision thermocouple sensors are indispensable because they provide the real-time, granular thermal feedback required to maintain the strict temperature gradients necessary for zirconium production. They serve as the critical link between the physical reaction and the automated control systems, ensuring the process strictly adheres to specific thermal windows during reduction and separation.

By integrating zonal temperature data with control logic, these sensors prevent thermal fluctuations that compromise impurity removal and physical structure, ultimately securing the chemical stability and uniform particle size of the final zirconium sponge.

Managing Critical Temperature Thresholds

The Reduction Phase Requirements

During the magnesium thermal reduction phase, the process demands a consistent temperature of 800 degrees Celsius. Even minor deviations at this stage can destabilize the reaction kinetics required to separate zirconium from its compounds.

The Vacuum Separation Phase Requirements

The vacuum separation process operates within a higher, narrower window of 900 to 1010 degrees Celsius. Precision here is non-negotiable, as this phase is responsible for the final purification of the sponge.

The Role of Real-Time Feedback

High-precision thermocouples do not just record data; they drive the system. They provide immediate feedback to heating elements, allowing the equipment to make micro-adjustments to maintain these specific setpoints.

The Risks of Thermal Instability

Impact on Impurity Removal

If the temperature fluctuates below the required threshold, the efficiency of removing impurities drops significantly. This results in a chemically unstable product that fails to meet purity standards.

The Danger of Over-Sintering

Conversely, if the temperature spikes or drifts too high, the zirconium sponge risks over-sintering. This degrades the physical structure of the product, leading to inconsistent particle sizes that are difficult to process further.

Ensuring Uniformity

The ultimate goal of preventing these fluctuations is uniformity. Precise control ensures that every batch of zirconium sponge exhibits consistent particle size and stable chemical composition.

Operational Implementation

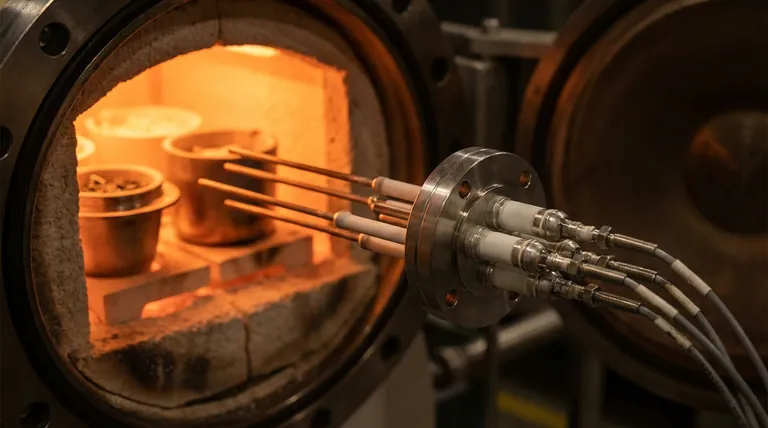

Multi-Zone Monitoring

Effective monitoring requires more than a single data point. Sensors must be arranged across different temperature zones within the reactor.

Controlling Temperature Gradients

This distributed arrangement allows operators to monitor and control temperature gradients across the entire vessel. It ensures that heat is distributed evenly, preventing localized hot spots or cold zones that could ruin the batch.

Understanding the Trade-offs

Complexity of Integration

While high-precision sensors offer superior control, they increase system complexity. Integrating multiple sensors across various zones requires a robust control system capable of processing simultaneous data streams without latency.

Calibration and Drift

Operating at temperatures up to 1010 degrees Celsius places stress on sensing elements. To maintain the "high precision" required to prevent over-sintering, these sensors require rigorous calibration schedules to ensure they have not drifted from their true values.

Making the Right Choice for Your Process

To maximize the quality of your zirconium sponge production, align your sensor strategy with your specific quality metrics:

- If your primary focus is Chemical Purity: Prioritize sensor accuracy in the 900-1010°C range to ensure maximum impurity removal efficiency during vacuum separation.

- If your primary focus is Physical Consistency: Ensure your sensors are distributed densely across all temperature zones to prevent gradients that lead to over-sintering and irregular particle sizes.

True process control is not just about heating material; it is about maintaining the discipline of the thermal environment.

Summary Table:

| Process Phase | Target Temperature Range | Critical Control Objective |

|---|---|---|

| Magnesium Thermal Reduction | 800°C | Stabilize reaction kinetics for compound separation |

| Vacuum Separation | 900°C - 1010°C | Maximum impurity removal and purification |

| Thermal Monitoring | Multi-Zone Distribution | Preventing over-sintering and ensuring uniform particle size |

Optimize Your Thermal Processes with KINTEK

Precise temperature control is the difference between a high-purity product and a failed batch. At KINTEK, we empower labs and manufacturers with the precision required for complex zirconium production. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to your unique thermal monitoring needs.

Ready to eliminate thermal fluctuations and secure chemical stability?

Contact our specialists today to discover how our advanced furnace solutions can enhance your production efficiency.

References

- М.М. Pylypenko, A.О. Drobyshevska. MAGNESIUM-THERMAL METHOD OF SPONGE ZIRCONIUM OBTAINING. DOI: 10.46813/2024-149-052

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What are most heating elements made of? Discover the Best Material for Your Heating Needs

- Why are silicon carbide heating elements suitable for high-temperature applications? Discover Their Key Benefits

- Why is a furnace system equipped with multiple thermocouples necessary for tungsten testing? Achieve Thermal Precision

- What type of heating elements are commonly used in both tube and box furnaces? Explore Key Choices for High-Temp Labs

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs

- What are the two most commonly used heating elements in modern sintering furnaces? Choose MoSi2 or SiC for High-Temp Success

- Why is graphite used in furnaces? Unlock Superior Performance for High-Temp Processes

- Why use silicon molybdenum rod furnaces for desulfurizer homogenization? Achieving 1400°C Thermal Stability