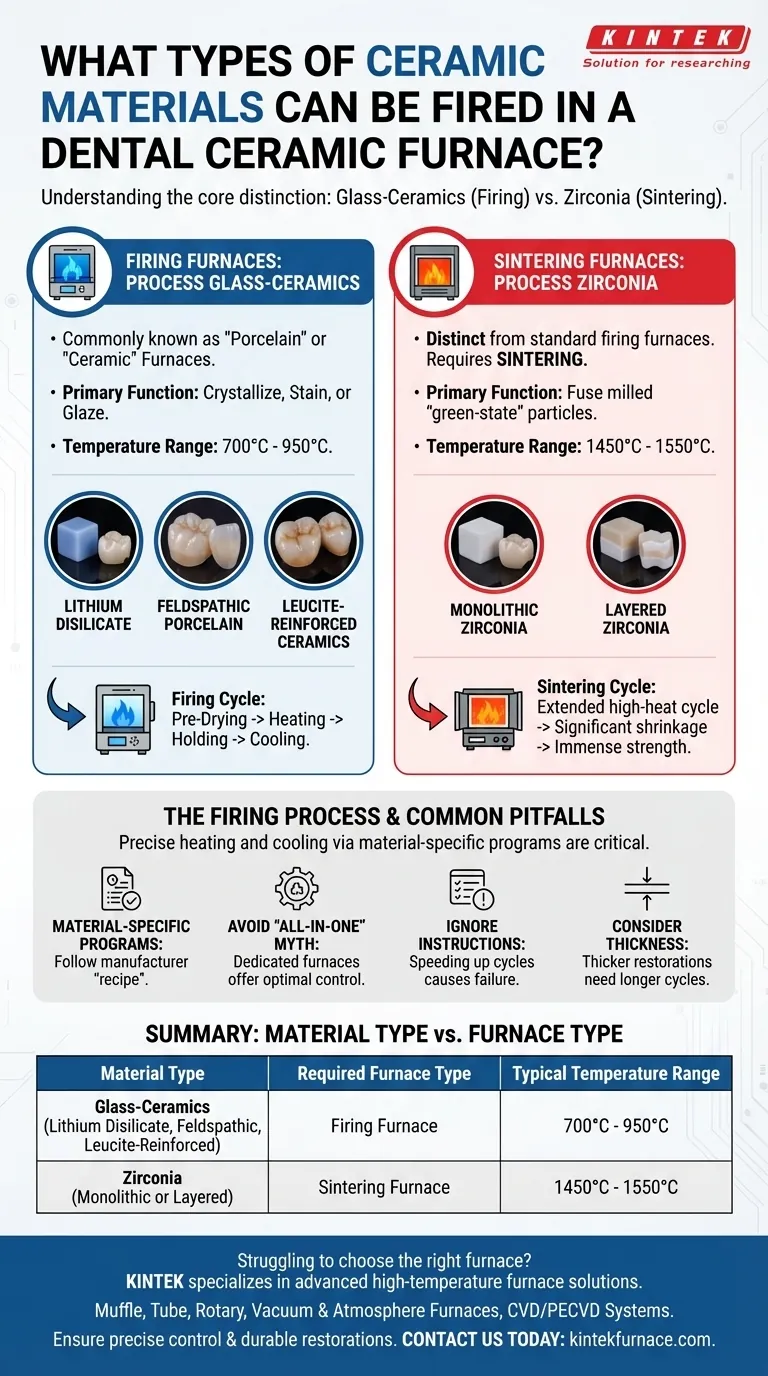

At its core, a dental ceramic furnace is designed to process glass-ceramic materials. This includes common restorative options like lithium disilicate, feldspathic porcelain, and leucite-reinforced ceramics. However, it's critical to understand that these furnaces are distinct from the high-temperature sintering furnaces required for processing zirconia, a common point of confusion.

The most important takeaway is that not all "dental ceramics" use the same furnace. A standard firing furnace is used for glass-ceramics like lithium disilicate, while a separate sintering furnace is required for zirconia due to its fundamentally different processing requirements and much higher temperatures.

The Two Core Categories of Dental Furnaces

Understanding the equipment starts with recognizing the two primary types of materials and the furnaces built to process them. The terms "firing" and "sintering" are not interchangeable; they describe different thermal processes for different material classes.

Firing Furnaces for Glass-Ceramics

These are the most common "porcelain" or "ceramic" furnaces. They are used to crystallize, stain, or glaze materials that have a significant glass component, typically operating at temperatures between 700°C and 950°C.

The primary materials for these furnaces are:

- Lithium Disilicate: This material is milled in a pre-crystallized "blue" state and requires a firing cycle in this furnace to achieve its final strength and tooth-like shade.

- Feldspathic Porcelain: This is the classic material used for layering over metal or zirconia substructures (PFM/PFZ) or for creating porcelain veneers. Each layer of porcelain requires a separate firing cycle.

- Leucite-Reinforced Ceramics: These materials also rely on a firing furnace to achieve their final esthetic properties through staining and glazing cycles.

Sintering Furnaces for Zirconia

Zirconia is a crystalline oxide ceramic with no glass matrix. It cannot be processed in a standard firing furnace because it requires a process called sintering.

Sintering involves heating the milled "green-state" or "chalky" zirconia to extremely high temperatures, typically between 1450°C and 1550°C. During this extended cycle, the individual zirconia particles fuse, causing the restoration to shrink significantly and gain its immense strength.

Understanding the Firing Process

A successful restoration depends on precisely controlling the heating and cooling of the ceramic. This is managed through pre-set programs specific to each material.

The Firing Cycle: More Than Just Heat

A modern firing program consists of multiple, carefully controlled stages.

- Pre-Drying: The furnace slowly heats to a low temperature to evaporate any moisture, which prevents thermal shock and cracking.

- Heating: The temperature is then raised at a specific rate (e.g., °C per minute) to the target firing temperature.

- Holding (Firing): The furnace holds the peak temperature for a set duration to allow the ceramic to fully mature, crystallize, or glaze.

- Cooling: Some programs control the cooling rate to prevent internal stresses from developing as the restoration returns to room temperature.

Why Material-Specific Programs are Critical

Each ceramic material has a unique "recipe"—a precise combination of temperatures, hold times, and heating rates. Using a program designed for lithium disilicate on a feldspathic porcelain will result in a failed restoration. The manufacturer of the ceramic material provides the exact program parameters required.

Common Pitfalls to Avoid

Mistakes in the firing process are costly and time-consuming. Understanding the limitations of your equipment and materials is essential for predictable success.

The Myth of the "All-in-One" Furnace

While some combination furnaces exist, they often represent a compromise. A dedicated high-temperature sintering furnace is optimized for the unique demands of zirconia. Likewise, a dedicated porcelain furnace offers more precise control for the nuances of glass-ceramics. For labs that process both materials regularly, separate, dedicated units are the professional standard.

Ignoring Manufacturer Instructions

The instructions provided by the ceramic manufacturer are the definitive guide. Technicians sometimes attempt to "speed up" cycles to save time, but this deviation is the most common cause of weak, cracked, or poorly shaded restorations.

Overlooking Restoration Thickness

The duration of a firing or sintering cycle is also influenced by the thickness of the restoration. Thicker crowns or bridges require longer, slower cycles to ensure heat penetrates evenly throughout the material, preventing internal stress and ensuring complete processing.

Making the Right Choice for Your Goal

To ensure a durable and esthetic outcome, you must match the material to the correct heating technology.

- If your primary focus is lithium disilicate (e.g., E.max) or feldspathic veneers: You need a programmable porcelain/firing furnace capable of precise temperature control for crystallization and glazing cycles.

- If your primary focus is monolithic or layered zirconia: You require a dedicated high-temperature sintering furnace that can reliably reach and hold temperatures around 1500°C.

- If your primary focus is layering porcelain onto zirconia frameworks (PFZ): You will need both a sintering furnace for the zirconia core and a separate porcelain furnace for applying the layers of feldspathic porcelain.

Matching the right material to the right furnace technology is the foundation of every successful dental restoration.

Summary Table:

| Material Type | Key Examples | Required Furnace Type | Typical Temperature Range |

|---|---|---|---|

| Glass-Ceramics | Lithium Disilicate, Feldspathic Porcelain, Leucite-Reinforced | Firing Furnace | 700°C - 950°C |

| Zirconia | Monolithic or Layered Zirconia | Sintering Furnace | 1450°C - 1550°C |

Struggling to choose the right furnace for your dental ceramics? KINTEK specializes in advanced high-temperature furnace solutions tailored for dental labs. With our strong R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs—whether you're firing glass-ceramics or sintering zirconia. Ensure precise temperature control and durable restorations—contact us today to discuss how our furnaces can elevate your lab's performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations