At its core, a dental zirconia sintering furnace requires a disciplined regimen of routine cleaning, professional calibration, and consistent environmental control. These maintenance tasks are not merely procedural; they are essential for guaranteeing the quality of dental restorations, ensuring operator safety, and protecting the significant investment the furnace represents.

The central takeaway is that furnace maintenance is not just a technical chore but a critical quality control process. Neglecting it directly compromises the mechanical properties and aesthetic finish of the zirconia restorations, ultimately impacting patient outcomes and lab profitability.

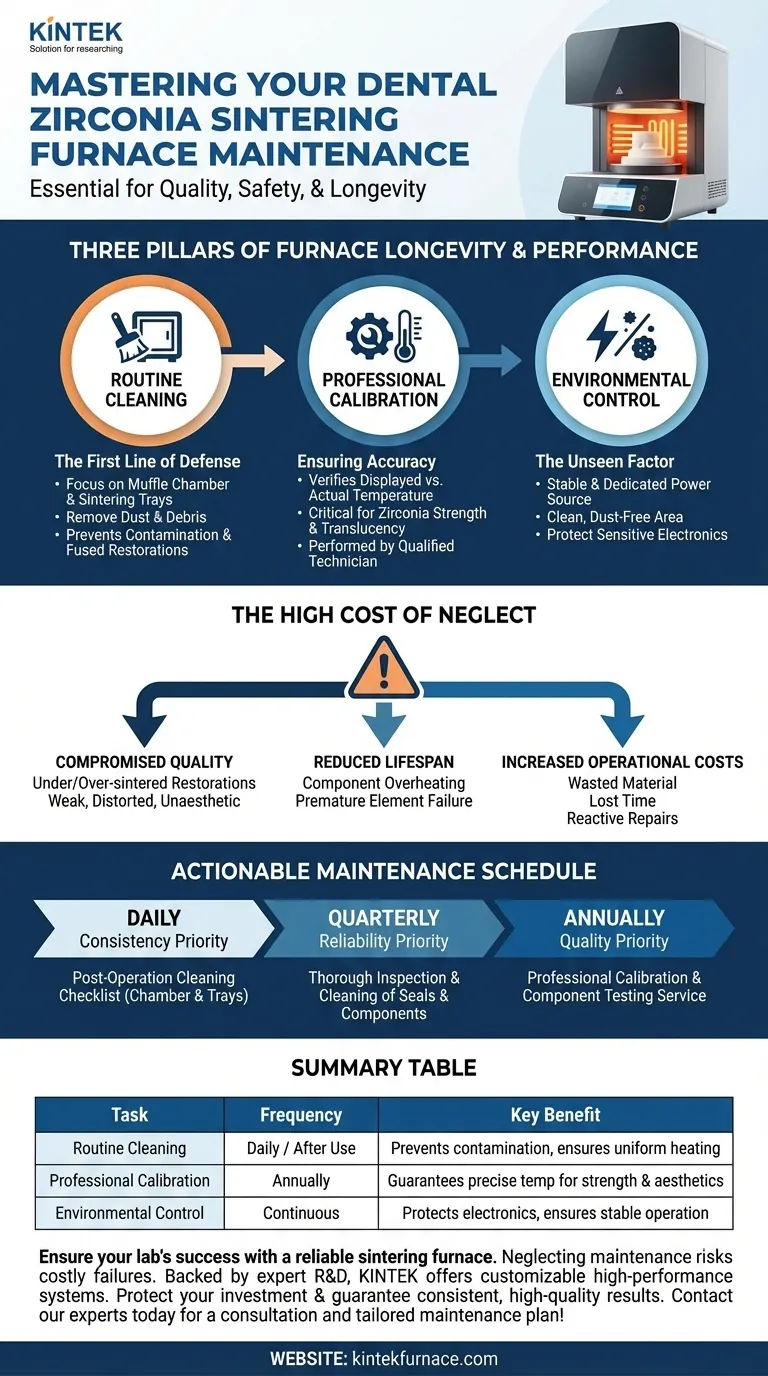

The Pillars of Furnace Longevity and Performance

Proper maintenance can be broken down into three fundamental areas. Each addresses a different aspect of the furnace's operation, and together they ensure consistent, reliable results.

Routine Cleaning: The First Line of Defense

Regularly cleaning the furnace is the most frequent and straightforward maintenance task. Contaminants can compromise the sintering process and the final restoration.

The primary focus should be on the furnace's muffle chamber and the sintering trays. Dust or debris can interfere with heat distribution and may fuse to restorations, causing defects. A clean exterior also prevents dust from entering the system.

Professional Calibration: Ensuring Accuracy

Calibration is the process of verifying that the temperature displayed by the furnace control matches the actual temperature inside the chamber. This is not optional.

Zirconia requires extremely precise temperature curves to achieve its target strength and translucency. Even a minor deviation can result in weak, discolored, or poorly fitting restorations. This critical task should be performed by a qualified technician.

Environmental Control: The Unseen Factor

The furnace's performance is heavily influenced by its operating environment. It requires a stable and dedicated power source to function correctly.

Power surges or inconsistent voltage can damage sensitive electronic components and heating elements. Furthermore, the furnace should be located in a clean, dust-free area to prevent contamination and ensure adequate ventilation for cooling cycles.

The High Cost of Neglect

Ignoring a regular service schedule introduces significant risks and hidden costs that go far beyond the price of a technician's visit.

Compromised Restoration Quality

The most immediate consequence of poor maintenance is a decline in the quality of your output. Inaccurate temperatures from a miscalibrated furnace can lead to under-sintered restorations that are weak and prone to fracture, or over-sintered ones that are distorted and unaesthetic.

Reduced Furnace Lifespan

A sintering furnace is a complex piece of equipment. Dust buildup can cause components to overheat, while uncalibrated heating cycles can place undue stress on the heating elements, leading to premature and costly failure.

Increased Operational Costs

The financial impact extends beyond repairs. A single failed batch due to a furnace malfunction means wasted zirconia, lost technician time, and delays in case delivery. Proactive maintenance is an investment that prevents these much larger, reactive expenses.

How to Apply This to Your Lab

Create a simple, structured maintenance schedule to ensure consistency and accountability.

- If your priority is daily consistency: Implement a post-operation cleaning checklist for the chamber and trays.

- If your priority is long-term reliability: Schedule a thorough inspection and cleaning of seals and components on a quarterly basis.

- If your priority is guaranteed quality: Commit to an annual service appointment with a qualified technician for professional calibration and component testing.

A well-maintained furnace is the foundation of a predictable, high-quality, and profitable dental laboratory.

Summary Table:

| Maintenance Task | Frequency | Key Benefit |

|---|---|---|

| Routine Cleaning (Chamber & Trays) | Daily / After Use | Prevents contamination, ensures uniform heating |

| Professional Calibration | Annually | Guarantees precise temperature for strength & aesthetics |

| Environmental Control (Power, Dust) | Continuous | Protects electronics, ensures stable operation |

Ensure your lab's success with a reliable sintering furnace. Neglecting maintenance risks costly failures and compromised dental restorations. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including high-performance sintering furnaces, all customizable for your unique dental lab needs. Protect your investment and guarantee consistent, high-quality results—contact our experts today for a consultation on the right furnace and a tailored maintenance support plan!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations