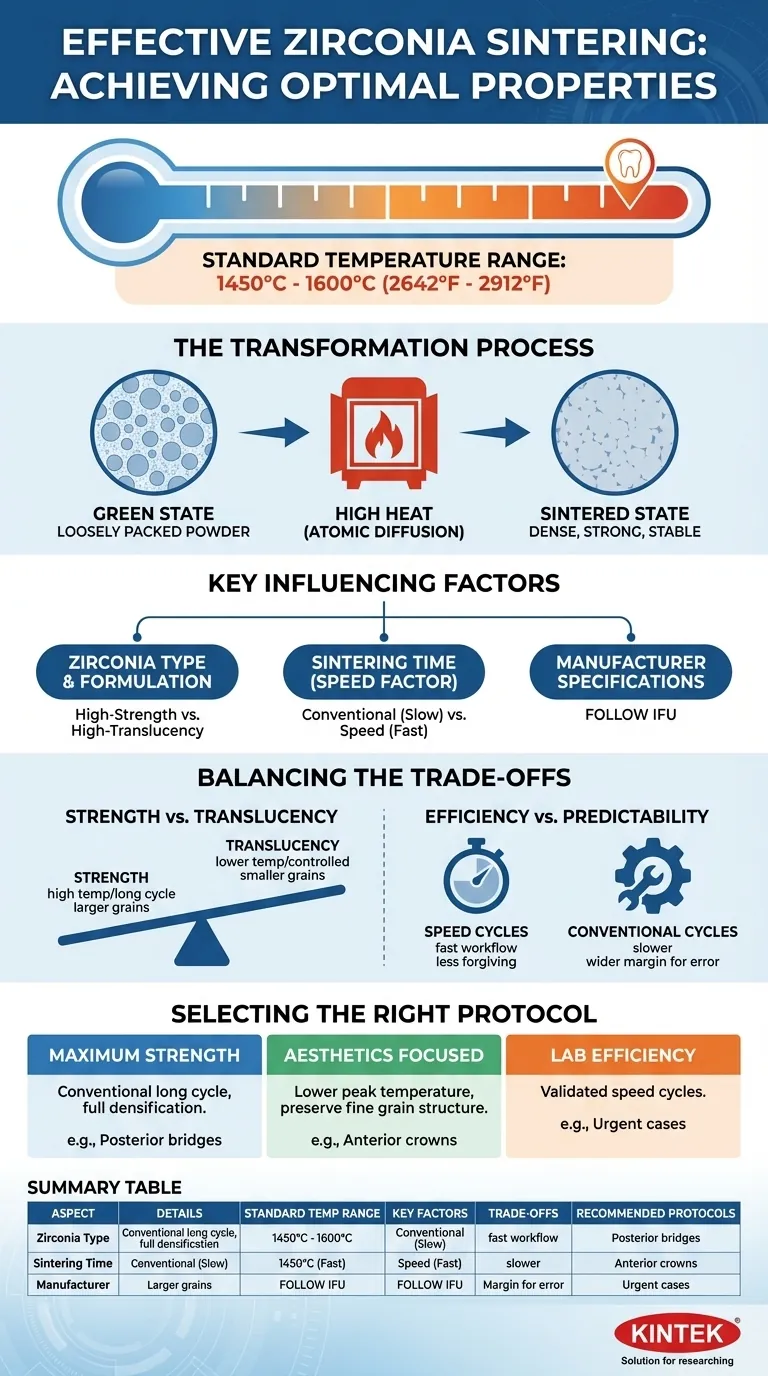

To achieve full densification and optimal properties, dental furnaces must operate within a specific high-temperature range for sintering zirconia. The standard temperature for sintering conventional dental zirconia typically falls between 1450°C and 1600°C (2642°F to 2912°F). This critical thermal process is what transforms the porous, chalk-like "green state" material into a dense, strong, and stable final restoration.

While the peak temperature is a critical benchmark, effective sintering is a function of a precise thermal cycle—the interplay of temperature, time, and heating/cooling rates. Simply hitting a target temperature is not enough; the entire process must be controlled to balance the final strength with the desired aesthetic translucency.

The Role of Temperature in Zirconia Transformation

Sintering is a process of atomic diffusion, where high heat provides the energy needed to fundamentally change the material's structure. Understanding this transformation is key to controlling the final outcome.

From Porous to Dense

In its pre-sintered state, zirconia is a compressed powder with significant empty space, or porosity, between its particles.

As the furnace temperature rises, these individual particles begin to fuse at their contact points. Reaching the target temperature of 1450°C to 1600°C provides enough energy to eliminate these pores, causing the material to shrink and achieve nearly 100% of its theoretical density.

Achieving Material Strength

The final flexural strength of the zirconia restoration is directly linked to its density. Incomplete sintering due to insufficient temperature leaves residual porosity within the material.

These pores act as microscopic stress concentrators and crack-initiation sites, severely compromising the structural integrity and long-term durability of the restoration.

The Impact of Grain Size

At a microscopic level, zirconia is composed of crystalline grains. The temperature and duration of the sintering cycle directly influence the final size of these grains.

Generally, higher temperatures or longer hold times at peak temperature lead to larger grain growth. This has significant implications for the material's optical and mechanical properties.

Factors Influencing the Ideal Sintering Cycle

The ideal temperature is not a single number but a variable within a range, dependent on the specific material and desired outcome.

Zirconia Type and Formulation

Modern dental zirconia comes in various formulations. High-strength opaque zirconias, used for posterior bridges, can be sintered at higher temperatures to maximize strength.

Conversely, high-translucency aesthetic zirconias, used for anterior crowns, often require slightly lower and more carefully controlled temperatures. Over-firing these materials can increase grain size, which scatters light and reduces the desired chameleon-like effect.

Sintering Time (The Speed Factor)

The time the material is held at its peak temperature is just as important as the temperature itself. Sintering cycles can range from a few hours to an overnight process.

"Speed" or "fast" sintering cycles use rapidly increasing temperatures and shorter hold times. Conventional cycles use slower heating rates and longer hold times, which is often considered the gold standard for achieving maximum strength and stability.

Manufacturer Specifications

Every zirconia disc or block is a unique chemical formulation. The manufacturer has invested heavily in determining the precise thermal protocol to achieve the advertised properties. Always treat the manufacturer's Instructions for Use (IFU) as the primary source of truth.

Understanding the Trade-offs

Choosing a sintering protocol involves balancing competing priorities. There is no single "best" cycle for all situations.

Strength vs. Translucency

This is the most critical trade-off in modern dental ceramics. Maximizing strength through high-temperature, long-duration sintering often leads to larger grain growth, which can increase opacity and decrease translucency. Achieving the highest aesthetic potential may require sacrificing a small amount of maximum strength.

Efficiency vs. Predictability

Speed sintering cycles significantly improve a dental lab's workflow and turnaround time. However, they can be less forgiving than conventional cycles.

The rapid heating and cooling can introduce internal stresses if not managed perfectly by a well-calibrated furnace, potentially impacting the marginal fit or long-term stability of the restoration. Conventional cycles are slower but offer a wider margin for error and more predictable results.

Selecting the Right Sintering Protocol

Your choice of sintering cycle should be a deliberate decision based on the clinical requirements of the case.

- If your primary focus is maximum strength (e.g., for a multi-unit posterior bridge): Adhere to the manufacturer's conventional, long-sintering cycle to ensure full densification and a robust grain structure.

- If your primary focus is aesthetics (e.g., for an anterior crown): Use a cycle specified for high-translucency materials, which may involve a lower peak temperature to preserve fine grain structure and optimize light transmission.

- If your primary focus is lab efficiency: A speed sintering cycle is a valid option, but only use protocols that have been explicitly validated by both the zirconia and furnace manufacturers to avoid compromising the restoration's integrity.

Ultimately, mastering zirconia sintering means moving beyond a single temperature and controlling the entire thermal process to perfectly match the material to the clinical need.

Summary Table:

| Aspect | Details |

|---|---|

| Standard Temperature Range | 1450°C to 1600°C (2642°F to 2912°F) |

| Key Factors | Zirconia type, sintering time, manufacturer specifications |

| Trade-offs | Strength vs. translucency, efficiency vs. predictability |

| Recommended Protocols | Conventional for strength, speed for efficiency, aesthetic-focused for translucency |

Unlock Precision in Your Dental Lab with KINTEK's Advanced Furnace Solutions

Struggling to achieve the perfect balance of strength and aesthetics in zirconia sintering? KINTEK specializes in high-temperature furnace technology tailored for dental laboratories. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we design solutions to precisely meet your unique experimental needs, ensuring reliable sintering cycles and superior restoration outcomes.

Contact us today to discuss how KINTEK can enhance your lab's efficiency and deliver consistent, high-quality results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations