In the context of dental and porcelain applications, ceramic furnaces typically operate in a temperature range of 600°C to 1,000°C (1112°F to 1832°F). However, this range represents only a specific subset of what "ceramic furnaces" are used for. The required temperature is fundamentally dictated by the material being processed and the desired thermal treatment.

The term "ceramic furnace" is broad; there is no single temperature range. The specific ceramic material and the intended process—whether sintering, annealing, or glazing—are the factors that truly define the required operating temperature, which can span from 600°C to well over 1,700°C.

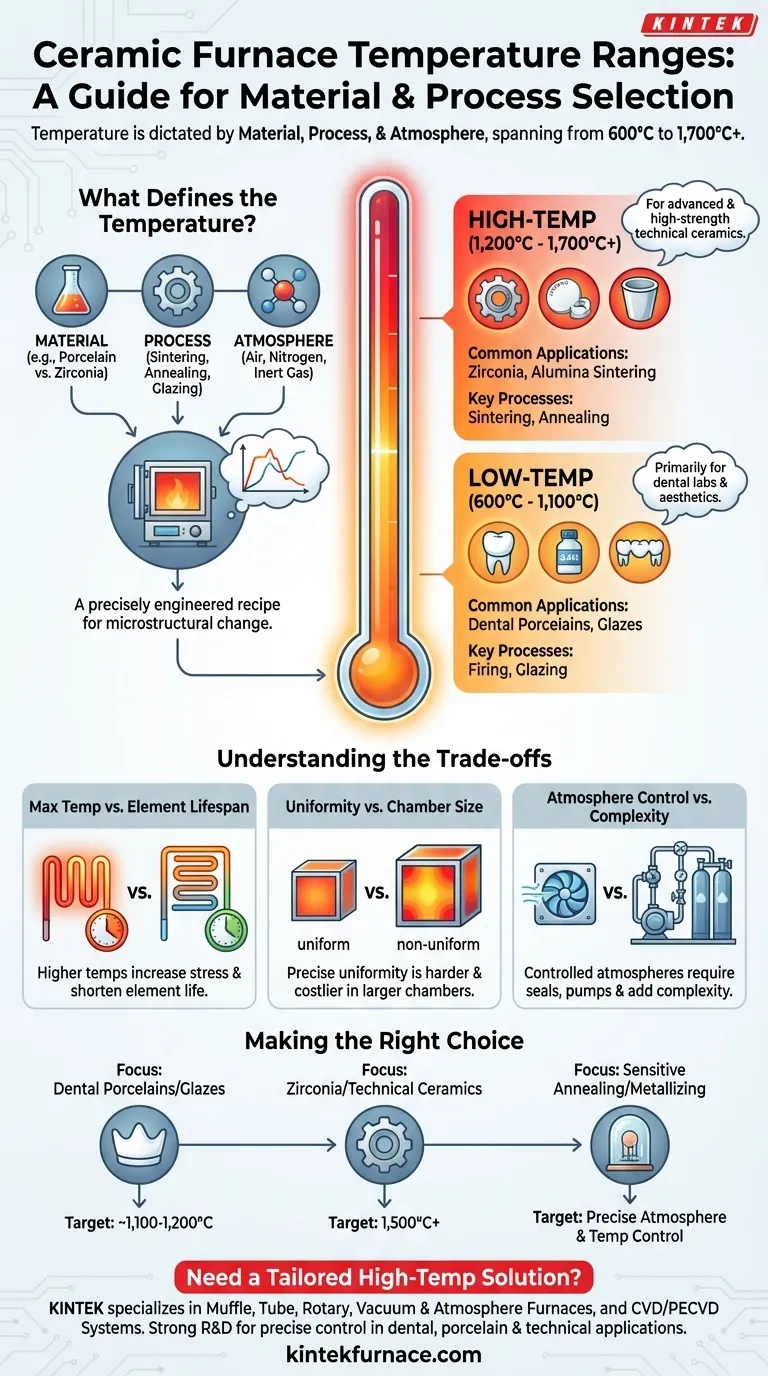

What Defines a Furnace's Operating Temperature?

The temperature profile of a furnace cycle is not arbitrary. It is a precisely engineered recipe designed to achieve a specific microstructural change in a material.

The Material Dictates the Process

Different ceramics have vastly different processing requirements. A furnace must be able to reach and hold the temperature needed to properly mature the specific material you are working with.

For example, feldspathic dental porcelains are fired at lower temperatures, often below 1,000°C. In contrast, sintering high-strength technical ceramics like zirconia requires much higher temperatures.

The Process Determines the Thermal Cycle

The goal of the heating process determines the entire temperature curve, including ramp rates, peak temperature, and hold times.

Common processes include:

- Sintering: Compacting and forming a solid mass of material by heat without melting it to the point of liquefaction.

- Annealing: Altering a material's microstructure to reduce hardness, increase ductility, and relieve internal stresses.

- Glazing/Firing: Applying a vitreous (glass-like) coating to a ceramic body, often for aesthetic or sealing purposes.

The Atmosphere's Critical Role

The atmosphere inside the furnace—be it air, nitrogen, an inert gas like argon, or even pure oxygen—is just as critical as the temperature. It prevents unwanted chemical reactions, such as oxidation, that could compromise the final properties of the ceramic component.

Common Temperature Ranges and Their Applications

While custom furnaces can be built for nearly any temperature, most commercial units fall into a few key categories based on their intended use.

Low-Temperature Processes (600°C - 1,100°C)

This is the range most commonly associated with dental lab furnaces. It is primarily used for firing low-fusing-point glasses and porcelains onto metal or ceramic substructures, as well as applying glazes and stains.

High-Temperature Sintering (1,200°C - 1,700°C+)

This range is required for processing advanced and high-strength technical ceramics. Sintering zirconia for dental crowns and bridges or alumina for industrial components occurs at these elevated temperatures, often requiring specialized heating elements.

Understanding the Trade-offs

Selecting a furnace involves balancing performance, capability, and cost. Understanding the inherent trade-offs is key to making an informed decision.

Maximum Temperature vs. Element Lifespan

Furnaces capable of reaching higher temperatures place greater stress on their heating elements (e.g., Kanthal vs. MoSi2). Running a furnace consistently near its maximum rated temperature will shorten the life of these critical components, increasing maintenance costs.

Temperature Uniformity vs. Chamber Size

Achieving precise and uniform temperature across the entire firing chamber is a significant engineering challenge. It is generally more difficult and expensive to maintain tight uniformity in a larger furnace than in a smaller one.

Atmosphere Control vs. Complexity

A simple furnace that operates only in air is far less complex and costly than a system designed for controlled atmospheres. Furnaces that manage inert gases or create a vacuum require additional seals, pumps, and control systems, adding to their expense and operational complexity.

Making the Right Choice for Your Application

To choose the correct furnace, you must first define your material and your process.

- If your primary focus is firing dental porcelains or glazes: A furnace with a maximum temperature around 1,100°C to 1,200°C will be sufficient.

- If your primary focus is sintering zirconia or other technical ceramics: You will need a high-temperature furnace capable of reliably reaching 1,500°C or more.

- If your primary focus is sensitive annealing or metallizing: Your priority should be a furnace with precise atmosphere control, in addition to accurate temperature management.

Understanding that the furnace is a tool to achieve a specific material outcome is the key to selecting the right equipment for your work.

Summary Table:

| Temperature Range | Common Applications | Key Processes |

|---|---|---|

| 600°C - 1,100°C | Dental porcelains, glazes | Firing, glazing |

| 1,200°C - 1,700°C+ | Zirconia, alumina sintering | Sintering, annealing |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK specializes in advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we ensure precise temperature control and performance for dental, porcelain, and technical ceramic applications. Contact us today to discuss how we can enhance your material processing efficiency and results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations