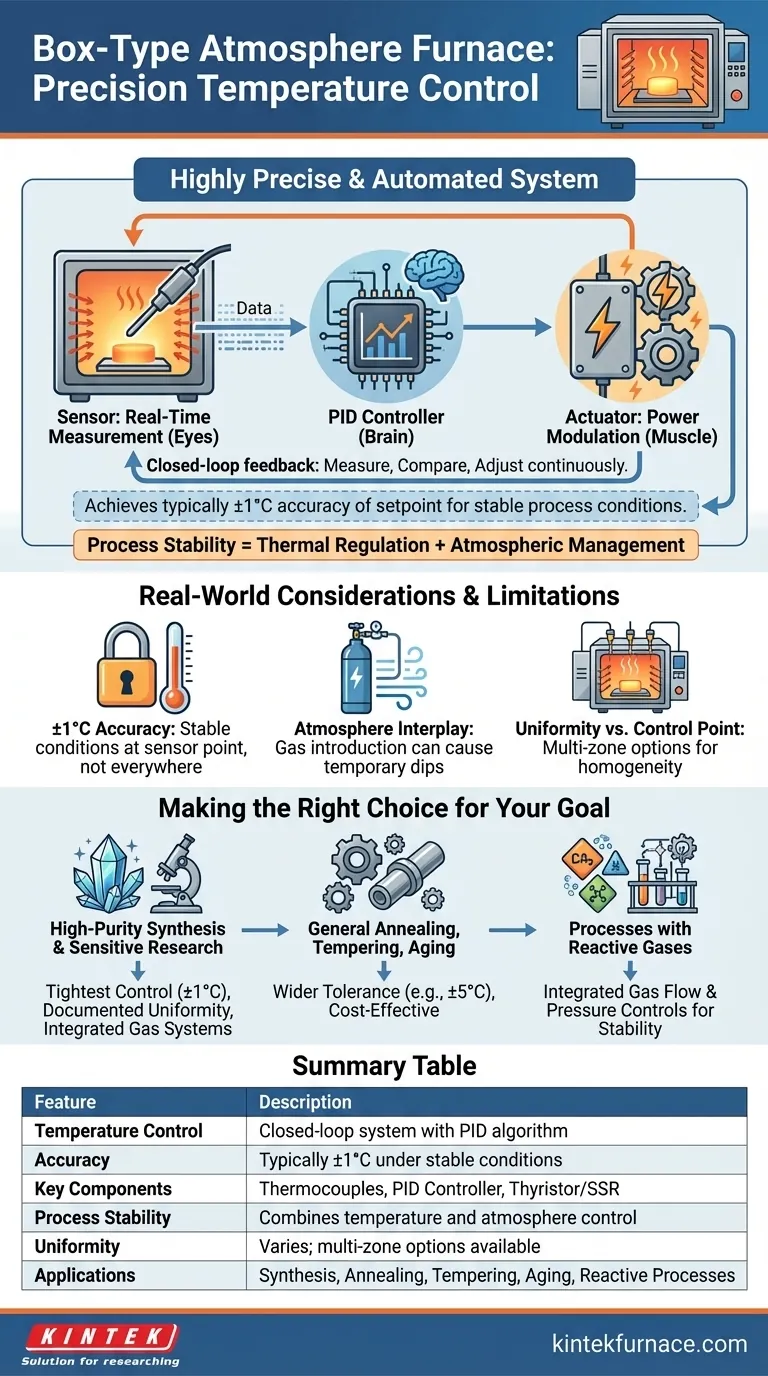

In short, a box-type atmosphere furnace offers highly precise and automated temperature control. It achieves this through a closed-loop system that continuously measures the internal temperature and adjusts heating power in real-time. This system typically uses high-precision sensors and an intelligent controller to maintain temperatures within a very narrow range, often as tight as ±1°C of the setpoint.

The furnace's true capability is not just temperature control, but process stability. It combines thermal regulation with atmospheric management to create a consistent, repeatable environment, which is the essential requirement for high-quality material processing and research.

How the Temperature Control System Works

A box-type atmosphere furnace operates on a classic feedback loop principle: measure, compare, and adjust. This cycle repeats continuously to hold the temperature precisely where you need it. The system is comprised of three critical components working in concert.

The Sensor: Real-Time Measurement

The system's "eyes" are high-precision thermocouples or thermistors. These sensors are placed inside the furnace chamber to get an accurate, real-time reading of the internal temperature.

This constant stream of data is the foundation for any adjustments the system makes. The quality and placement of this sensor are critical for accuracy.

The Brain: The PID Controller

The data from the sensor is fed to an intelligent temperature controller, which acts as the system's brain. This controller almost always uses a PID (Proportional-Integral-Derivative) algorithm.

The PID controller doesn't just see the current temperature; it analyzes how fast the temperature is changing (Derivative) and how far it has been from the setpoint over time (Integral). This allows it to make sophisticated, predictive adjustments to avoid overshooting or undershooting the target temperature.

The Muscle: The Actuator

Based on the PID controller's decisions, an actuator modulates the power sent to the heating elements. This is typically a thyristor regulator or a solid-state relay (SSR).

Instead of a simple on/off switch, this component can finely tune the electrical power, delivering just enough energy to maintain a stable thermal environment.

Understanding the Practical Limitations

While modern furnaces offer exceptional control, their datasheet specifications represent ideal conditions. Real-world performance involves trade-offs that are important to understand.

The Meaning of "±1°C Accuracy"

A specification like ±1°C accuracy refers to the system's ability to hold a stable temperature (a "soak") under steady conditions. It does not mean every cubic centimeter of the furnace is at that exact temperature.

Factors like the size and thermal mass of your workpiece, the ramp rate, and the introduction of process gases can create temporary, localized temperature variations.

The Interplay of Temperature and Atmosphere

Atmosphere control is integral to the furnace's function but also adds complexity. Introducing a cool inert or reducing gas will inevitably cause a slight temperature dip.

The PID controller must be well-tuned to sense this dip and respond quickly without overcompensating, ensuring the thermal cycle remains within your process window.

Uniformity vs. Control Point

The controller maintains the setpoint temperature at the location of the thermocouple. Temperature uniformity across the entire chamber can vary, especially in larger furnaces.

For processes requiring extreme uniformity, look for furnaces with multiple heating zones and corresponding control loops, which create a more homogenous thermal environment.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the sensitivity of your process. You must match the furnace's capabilities to your specific material or experimental requirements.

- If your primary focus is high-purity material synthesis or sensitive research: Prioritize a furnace with the tightest control accuracy (±1°C), documented temperature uniformity, and integrated gas management systems.

- If your primary focus is general annealing, tempering, or aging: A furnace with a slightly wider tolerance (e.g., ±5°C) is often sufficient and can be a more cost-effective solution.

- If your primary focus is processes involving reactive gases: Pay close attention to how well the gas flow and pressure controls are integrated with the temperature control system to ensure process stability.

Ultimately, understanding these control systems empowers you to select a furnace that will deliver the consistent and repeatable results your work demands.

Summary Table:

| Feature | Description |

|---|---|

| Temperature Control | Closed-loop system with PID algorithm for real-time adjustments |

| Accuracy | Typically ±1°C under stable conditions |

| Key Components | Thermocouples/sensors, PID controller, thyristor/SSR actuator |

| Process Stability | Combines temperature and atmosphere control for repeatable results |

| Uniformity | Varies by furnace size; multi-zone options available for better uniformity |

| Applications | Material synthesis, annealing, tempering, aging, and reactive gas processes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precise, customizable options like Box-Type Atmosphere Furnaces, Muffle, Tube, Rotary, Vacuum Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met for superior process stability and efficiency. Contact us today to discuss how we can enhance your material processing and research outcomes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity