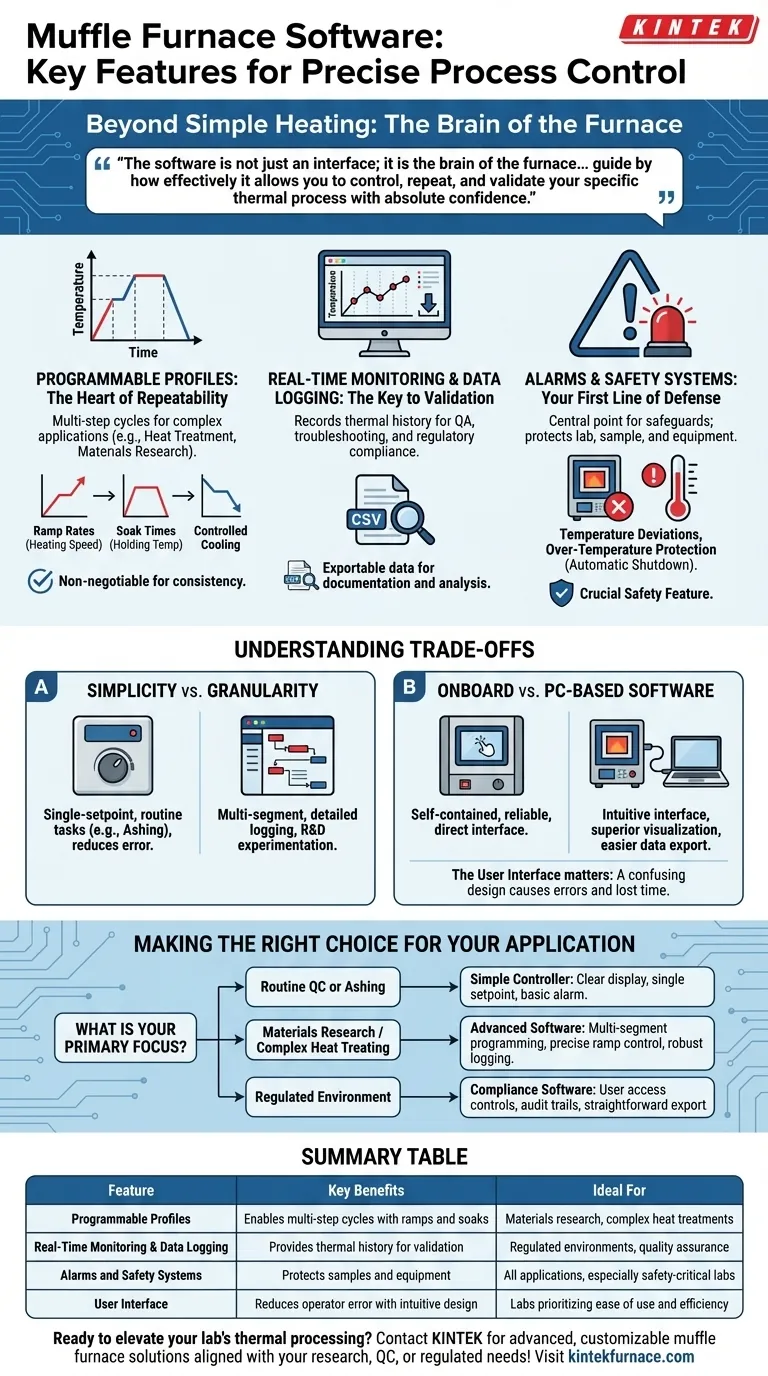

When selecting a muffle furnace, the most critical software features to consider are programmable controls for temperature profiles, real-time monitoring and data logging, and integrated safety systems like alarms and over-temperature protection. These features move beyond simple heating to provide the core functions of process control: repeatability, validation, and safety.

The software is not just an interface; it is the brain of the furnace. Your choice should be guided not by a list of features, but by how effectively the software allows you to control, repeat, and validate your specific thermal process with absolute confidence.

Beyond "On/Off": Achieving True Process Control

The purpose of furnace software is to translate your procedural requirements into a reliable and repeatable thermal cycle. This goes far beyond simply setting a temperature.

Programmable Profiles: The Heart of Repeatability

A basic controller allows you to set a single target temperature. Advanced, programmable software is essential for processes requiring multiple steps.

This includes setting specific ramp rates (how quickly the temperature rises), soak times (how long it holds at a temperature), and controlled cooling steps. This level of control is non-negotiable for applications like complex heat treatments, materials research, or ceramic firing.

Real-Time Monitoring and Data Logging: The Key to Validation

Seeing the current temperature is standard. True process control requires knowing the entire thermal history of your run.

Look for software that can log temperature data over time. The ability to export this data (e.g., as a CSV file) is crucial for quality assurance, troubleshooting failed processes, and providing documentation for reports or regulatory compliance.

Alarms and Alerts: Your First Line of Defense

Alarms are not a convenience; they are a critical safety and sample protection feature. The software is the central point for configuring these safeguards.

Modern systems should allow you to set alarms for temperature deviations (if the furnace strays too far from its setpoint) and, most importantly, over-temperature protection. This feature automatically shuts down the furnace if it exceeds a maximum safe temperature, protecting the furnace, your lab, and your sample.

Understanding the Trade-offs

More features are not always better. The key is to match the software's capability to your lab's actual needs and avoid paying for complexity you won't use.

Simplicity vs. Granularity

A furnace dedicated to a single, repetitive task like ashing may benefit from a simple, single-setpoint controller. The lack of complexity reduces the chance of operator error.

Conversely, a research and development environment demands granular control. These users need multi-segment programming and detailed data logging to experiment with and perfect new processes.

Onboard vs. PC-Based Software

Many furnaces are controlled entirely through a built-in digital interface. This is self-contained and reliable.

However, furnaces that can connect to a PC often offer a more intuitive interface for programming complex profiles, superior data visualization, and easier data export. The trade-off may be a reliance on a dedicated computer.

The Hidden Cost of a Poor User Interface

Even the most powerful software is a liability if it is difficult to use. A confusing or poorly designed interface is a direct cause of operator error, leading to ruined samples and lost time. During a product demonstration, ensure that programming a typical cycle feels logical and straightforward.

Making the Right Choice for Your Application

Choose the software that best enables your specific goal.

- If your primary focus is routine QC or ashing: A simple controller with a clear display, single setpoint programming, and a basic over-temperature alarm is efficient and sufficient.

- If your primary focus is materials research or complex heat treating: Prioritize software with multi-segment programming (ramps and soaks), precise ramp rate control, and robust data logging capabilities.

- If your primary focus is working in a regulated environment: Look for software with user access controls, audit trails, and straightforward data export features to meet validation requirements.

Ultimately, the right software empowers you to master your thermal processes, turning a simple hot box into a precise scientific instrument.

Summary Table:

| Feature | Key Benefits | Ideal For |

|---|---|---|

| Programmable Profiles | Enables multi-step cycles with ramps and soaks for repeatability | Materials research, complex heat treatments |

| Real-Time Monitoring & Data Logging | Provides thermal history for validation and compliance | Regulated environments, quality assurance |

| Alarms and Safety Systems | Protects samples and equipment with over-temperature alerts | All applications, especially safety-critical labs |

| User Interface | Reduces operator error with intuitive design | Labs prioritizing ease of use and efficiency |

Ready to elevate your lab's thermal processing with tailored muffle furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs—whether you're in research, quality control, or regulated industries. Contact us today to discuss how our expertise can enhance your process control and efficiency!

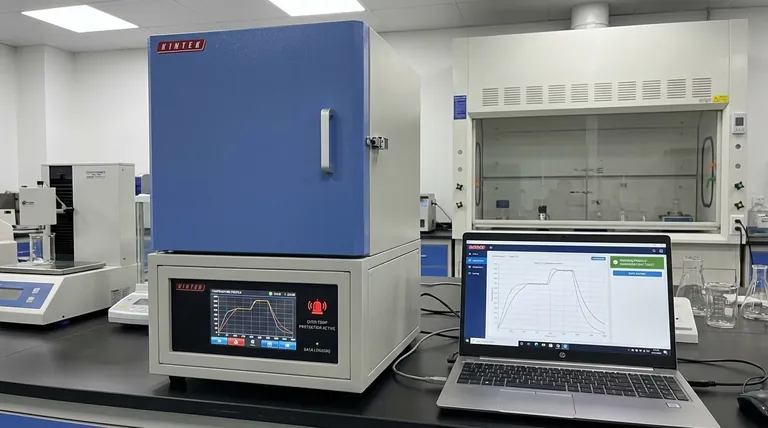

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating