A safe muffle furnace is defined by a multi-layered system of thermal, electrical, and operational protections. The most critical features include over-temperature protection to prevent catastrophic failure, earth leakage breakers to mitigate electrical shock, and robust self-diagnostic functions that continuously monitor the furnace's health. Additional key elements are physical insulation, fume extraction systems, and alarms that alert operators to any deviation from safe operating parameters.

Muffle furnaces combine extreme temperatures with high electrical power, creating inherent risks. True safety is not achieved by a single feature, but through an integrated system designed to protect the operator from harm, the process from failure, and the equipment from damage.

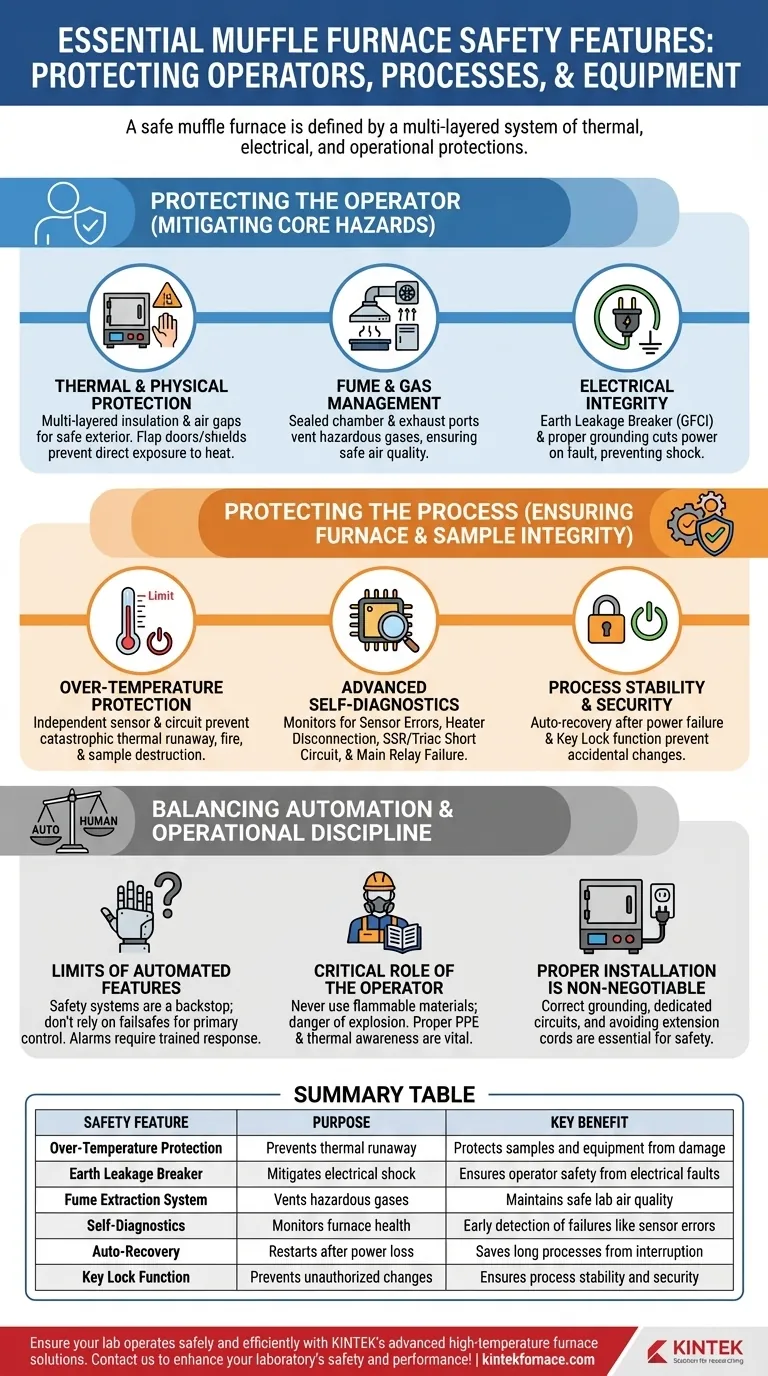

Protecting the Operator: Mitigating Core Hazards

The primary goal of any safety system is to protect the people using the equipment. For a muffle furnace, the risks are primarily thermal, electrical, and chemical.

Thermal and Physical Protection

A furnace's most obvious danger is its extreme heat. Modern designs incorporate features to isolate the operator from high temperatures.

This includes multi-layered insulation and an air gap between the inner and outer casings to keep the exterior surfaces at a safe-to-touch temperature. Some models also feature flap doors or safety shields that prevent direct exposure to the hot chamber when the door is opened.

Fume and Gas Management

Many high-temperature processes release gases or fumes that can be hazardous if inhaled. A sealed muffle chamber is the first line of defense, isolating the sample from the heating elements and containing byproducts.

Crucially, many furnaces must be equipped with an exhaust port or ventilation system. This allows for the safe venting of aggressive or toxic gases, ensuring a safe breathing environment in the laboratory.

Electrical Integrity

High-power heating elements demand robust electrical safety. A fundamental feature is an earth leakage breaker or Ground Fault Circuit Interrupter (GFCI), which immediately cuts power if it detects a fault that could lead to electric shock.

Proper grounding of the furnace chassis is non-negotiable. This ensures that in the event of an internal short circuit, the current is safely directed to the ground rather than through an operator. The furnace should always be connected to a dedicated, properly rated circuit.

Protecting the Process: Ensuring Furnace and Sample Integrity

Beyond operator safety, these features are designed to protect the integrity of your work and the significant investment the furnace represents.

Over-Temperature Protection

This is arguably the most important single safety feature. It is an independent monitoring circuit with its own sensor that will shut down the furnace if the main temperature controller fails and the temperature exceeds a user-set limit.

Without this, a controller failure could lead to thermal runaway, destroying the sample, the furnace's heating elements, and creating a significant fire hazard.

Advanced Self-Diagnostics

High-end furnaces actively monitor their own internal state. These self-diagnostic functions provide an early warning of potential failures before they become critical.

Key systems monitored include:

- Sensor Errors: Detects a broken or disconnected thermocouple.

- Heater Disconnection: Senses a break in a heating element.

- SSR/Triac Short Circuit: Identifies a failure in the solid-state relays that control power to the elements, a common cause of overheating.

- Main Relay Failure: Ensures the primary power-cutting relay is functional.

Process Stability and Security

Features in this category prevent accidental process changes and ensure reliable operation. Auto-recovery after a power failure can automatically restart a heating program once power is restored, saving a long process from being ruined.

A key lock function is a simple but effective feature that prevents unauthorized users or accidental bumps from changing critical temperature or time settings during a run.

Understanding the Trade-offs: Automated vs. Operational Safety

Built-in safety features are a critical backstop, but they cannot replace disciplined operational procedures. Understanding their limitations is key to a truly safe environment.

The Limits of Automated Features

Safety systems are designed to prevent catastrophic failure, not to correct for improper use. Over-temperature protection is a failsafe, but relying on it to control your process means your primary controller is already failing.

Alarms and diagnostics are only effective if operators are trained to understand and respond to them correctly.

The Critical Role of the Operator

No furnace is designed to safely contain flammable, volatile, or explosive materials. Placing such items in a muffle furnace can lead to pressure buildup and explosion, bypassing all built-in safety mechanisms. This is a procedural, not a technical, safeguard.

Likewise, operators must be trained to handle hot materials with appropriate personal protective equipment (PPE) and to be aware of thermal hazards even after the furnace has been turned off.

Proper Installation is Non-Negotiable

Safety features are rendered useless if the furnace is not installed correctly. Using extension cords, overloading circuits, or failing to properly ground the unit creates significant electrical and fire risks that no internal feature can mitigate.

How to Select a Furnace Based on Your Safety Priorities

Your specific application will determine which safety features to prioritize.

- If your primary focus is operator safety in a busy lab: Prioritize excellent external insulation, a secure door latch, and a mandatory fume extraction system.

- If your primary focus is protecting high-value or irreplaceable samples: Insist on a furnace with independent over-temperature protection and advanced self-diagnostics to prevent process loss.

- If your primary focus is running long, unattended processes: Look for robust self-diagnostics, alarms that can be monitored remotely, and an auto-recovery function for power failures.

A truly safe muffle furnace is one where intelligent engineering design and disciplined operational procedure work in perfect tandem.

Summary Table:

| Safety Feature | Purpose | Key Benefit |

|---|---|---|

| Over-Temperature Protection | Prevents thermal runaway | Protects samples and equipment from damage |

| Earth Leakage Breaker | Mitigates electrical shock | Ensures operator safety from electrical faults |

| Fume Extraction System | Vents hazardous gases | Maintains safe lab air quality |

| Self-Diagnostics | Monitors furnace health | Early detection of failures like sensor errors |

| Auto-Recovery | Restarts after power loss | Saves long processes from interruption |

| Key Lock Function | Prevents unauthorized changes | Ensures process stability and security |

Ensure your lab operates safely and efficiently with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Protect your operators and processes—contact us today to discuss how our tailored solutions can enhance your laboratory's safety and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency