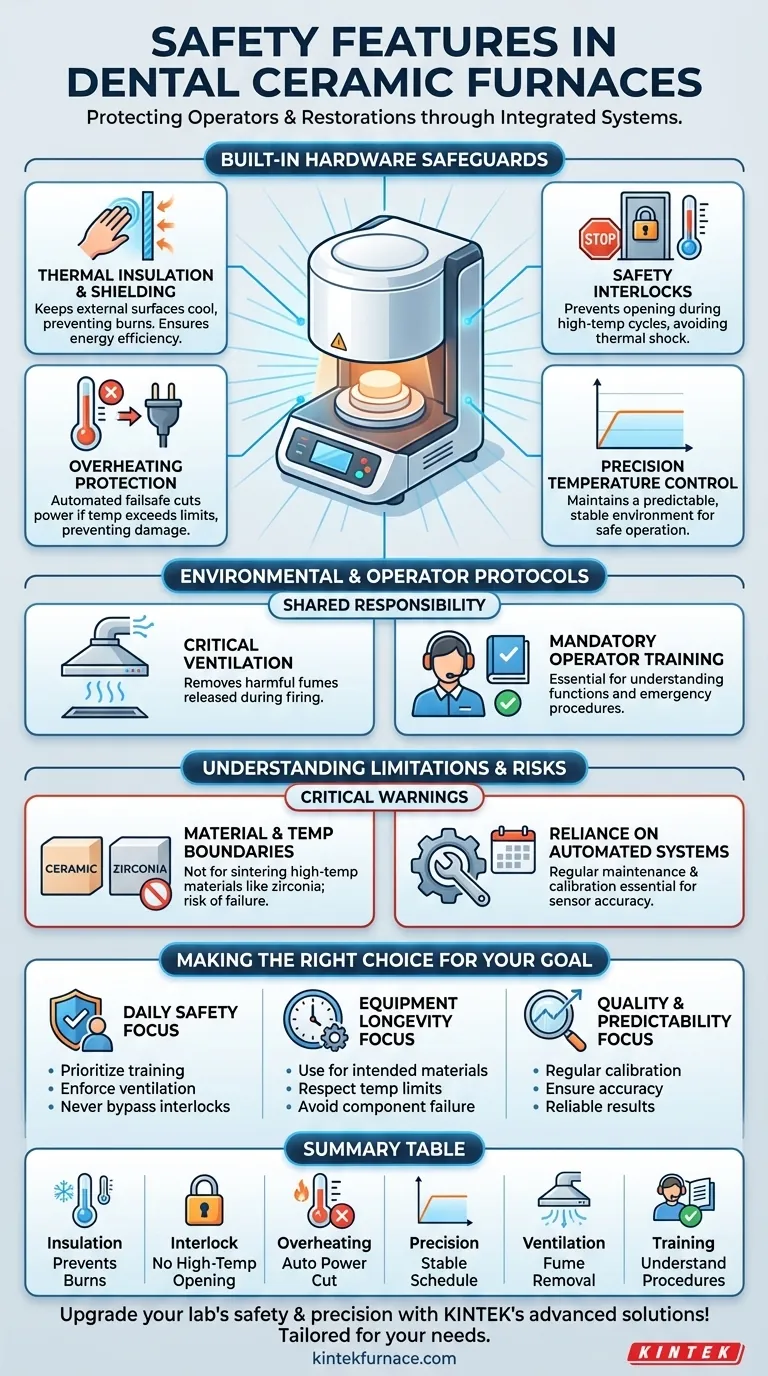

At their core, dental ceramic furnaces are engineered with several integrated safety systems to protect both the operator and the integrity of the dental restoration. The primary safety features are robust thermal insulation to maintain a cool external surface, safety interlocks that prevent the chamber from being opened during a high-temperature firing cycle, and automated controls to prevent overheating.

A dental furnace's safety is not just a list of features, but a system. It's a partnership between the furnace's built-in hardware safeguards and the mandatory safety protocols—like proper ventilation and training—that must be followed by the operator.

Built-in Hardware Safeguards

Modern dental ceramic furnaces are designed with multiple layers of protection to contain the intense heat required for firing porcelain. These features work automatically to minimize risk during operation.

Thermal Insulation and Shielding

The furnace chamber is lined with high-quality thermal insulation. This material serves two purposes: it prevents heat loss for energy efficiency and, more critically, it keeps the external surfaces of the unit at a safe temperature to prevent accidental burns.

Safety Interlocks

Nearly all modern furnaces are equipped with a safety interlock on the firing chamber door or lift. This mechanical or electronic lock prevents the furnace from being opened while it is operating or above a certain temperature, protecting the user from a blast of hot air and thermal shock.

Overheating Protection

Furnaces use precise thermocouples to monitor internal temperatures. If the temperature exceeds the programmed limit due to a malfunction, an automated failsafe will cut power to the heating elements. This critical feature prevents catastrophic damage to the furnace, the dental restoration, and the surrounding lab environment.

Precision Temperature Control

While primarily for aesthetic results, precise, automated temperature control is also a safety feature. By ensuring the furnace accurately follows a programmed firing schedule without unexpected temperature spikes, it maintains a predictable and stable operating environment.

Environmental and Operator Safety Protocols

The safety of a furnace extends beyond the machine itself. The environment it's used in and the knowledge of the person operating it are just as important.

The Critical Need for Ventilation

During the firing process, certain binding agents or materials within the dental ceramic can release fumes. These furnaces must be operated in a well-ventilated area or connected to an appropriate exhaust system to prevent the buildup of potentially harmful fumes in the laboratory.

Mandatory Operator Training

A furnace is a sophisticated piece of equipment. Dental professionals must receive proper training before operating it. This ensures they understand the specific functions, safety warnings, and emergency procedures for their particular model. An untrained operator can inadvertently bypass safety features or create a hazardous situation.

Understanding the Limitations and Risks

To use a ceramic furnace safely, you must also understand what it is not designed to do. Misusing the equipment is a primary source of risk.

Material and Temperature Boundaries

Ceramic furnaces, which often use Kanthal or Nichrome heating elements, operate in a lower temperature range suitable for conventional porcelains. They are not sintering furnaces. Attempting to fire high-temperature materials like zirconia in a standard ceramic furnace can exceed its design limits, leading to equipment failure and creating a significant safety hazard.

Reliance on Automated Systems

The full automation of these furnaces is a major benefit, but it means operators must trust the device's sensors and calibration. Regular maintenance and calibration checks are essential to ensure the automated safety features are functioning correctly.

Making the Right Choice for Your Goal

Ensuring safety involves a combination of relying on the furnace's features and implementing strict lab protocols.

- If your primary focus is daily operator safety: Prioritize consistent operator training, enforce the use of proper ventilation, and never attempt to bypass the door interlocks.

- If your primary focus is equipment longevity: Use the furnace only for its intended materials (dental ceramics) and respect its maximum temperature limitations to avoid component failure.

- If your primary focus is quality control and predictable results: Ensure your furnace undergoes regular calibration to confirm its temperature accuracy, which underpins both the quality of the restoration and the reliability of its safety systems.

Ultimately, achieving a safe and efficient workflow is a shared responsibility between the technology's design and the user's expertise.

Summary Table:

| Safety Feature | Description |

|---|---|

| Thermal Insulation | Keeps external surfaces cool to prevent burns and ensures energy efficiency. |

| Safety Interlocks | Prevents chamber opening during high-temperature cycles to avoid thermal shock. |

| Overheating Protection | Automatically cuts power if temperature exceeds limits to prevent damage. |

| Precision Temperature Control | Maintains stable firing schedules for predictable, safe operation. |

| Ventilation Requirements | Essential for fume removal to protect against harmful emissions in the lab. |

| Operator Training | Mandatory for understanding functions, warnings, and emergency procedures. |

Upgrade your dental lab's safety and precision with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure they meet your unique experimental needs, enhancing operator protection and equipment reliability. Contact us today to discuss how our tailored solutions can benefit your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab