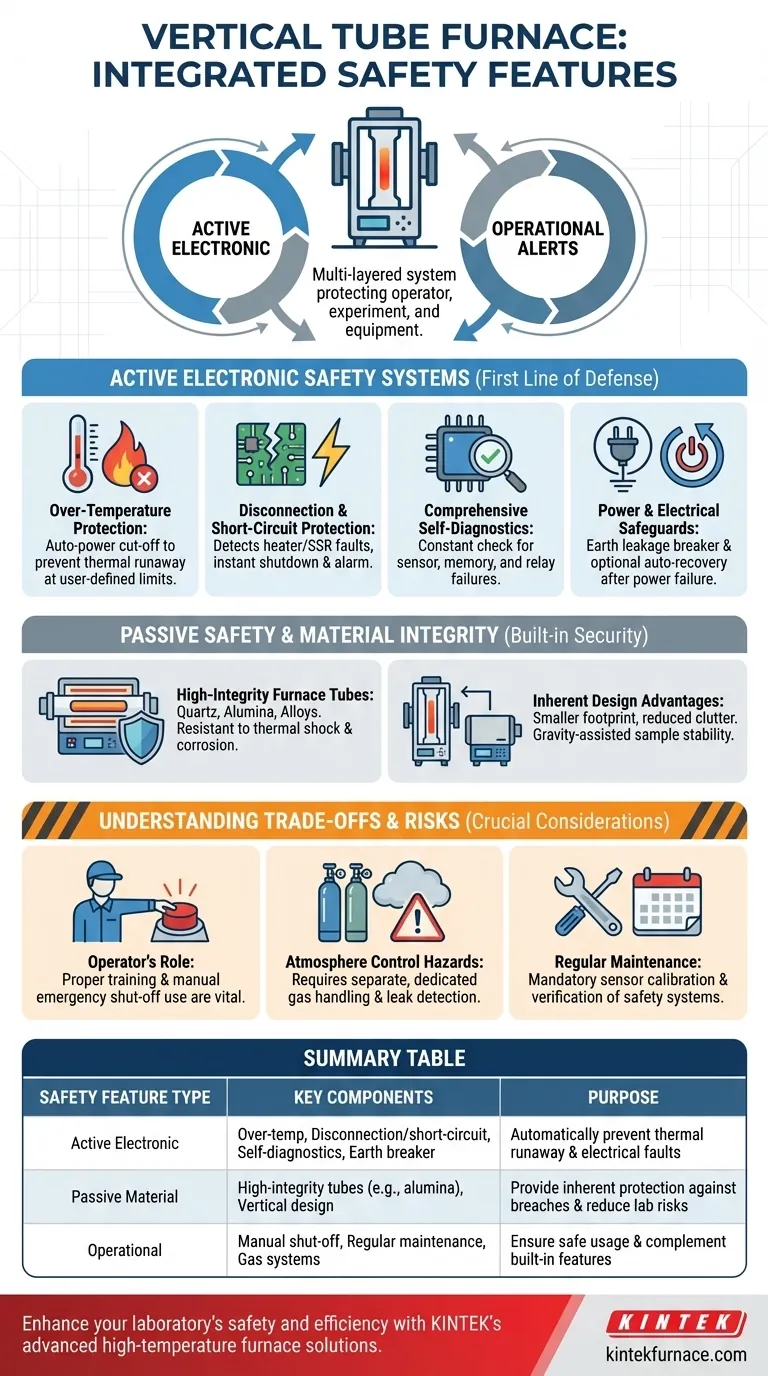

At its core, a vertical tube furnace is equipped with a multi-layered safety system designed to protect the operator, the experiment, and the equipment itself. The primary safety features include active electronic controls like over-temperature protection that automatically cuts power, emergency shut-off mechanisms, and self-diagnostic functions that monitor for component failure. These are complemented by passive safeguards, such as the use of high-integrity materials for the furnace tube to prevent failure at extreme temperatures.

The safety of a vertical tube furnace is not defined by a single feature, but by an integrated system of active electronic protections, passive material safeguards, and clear operational alerts that work together to mitigate risk.

Active Electronic Safety Systems

Modern vertical tube furnaces rely on a suite of intelligent electronic systems to actively prevent hazardous situations before they occur. These are the first line of defense during operation.

Over-Temperature Protection

This is arguably the most critical safety feature. A dedicated sensor, separate from the primary control thermocouple, monitors the furnace temperature. If it exceeds a user-defined safety limit, the system automatically cuts all power to the heating elements, preventing thermal runaway, sample destruction, and damage to the furnace.

Disconnection and Short-Circuit Protection

The furnace continuously monitors its own electrical integrity. It can detect a heater disconnection or an SSR (Solid State Relay) short circuit. In either event, the controller will immediately shut down the system and trigger an alarm to prevent unpredictable heating behavior or electrical hazards.

Comprehensive Self-Diagnostic Functions

Advanced furnaces perform a constant self-check on their core components. This system can identify and alert the operator to a range of potential failures, including:

- Sensor or memory errors

- Triac or SSR short circuits

- Heater or main relay disconnection

This allows for proactive maintenance and prevents a user from starting a process with a compromised, unsafe system.

Power and Electrical Safeguards

Beyond the heating controls, furnaces are equipped with fundamental electrical protection. An earth leakage breaker is a crucial component that protects operators from electric shock in the event of an internal fault. Additionally, some models offer auto-recovery after a power failure, which can be configured to safely resume or terminate a process once power is restored.

Passive Safety and Material Integrity

Safety is also engineered into the physical construction and design of the furnace. These passive features provide a robust foundation of security that doesn't rely on active electronics.

High-Integrity Furnace Tubes

The furnace tube is the heart of the system, containing the high-temperature environment. These tubes are made from carefully selected materials like high-purity quartz, alumina ceramic, or specialized metal alloys. This material choice ensures high resistance to thermal shock and corrosion, preventing a catastrophic breach that could release heat and hazardous atmospheres.

Inherent Design Advantages

The vertical orientation itself contributes to safety. A vertical furnace typically has a smaller footprint than a comparable horizontal model, reducing clutter in a lab environment and minimizing trip hazards. This design also uses gravity to ensure samples are positioned consistently, which can contribute to more stable and predictable processes.

Understanding the Trade-offs and Risks

Even the most advanced furnace has limitations. Understanding them is key to maintaining a truly safe operating environment.

The Critical Role of the Operator

Safety features are a backstop, not a substitute for proper procedure. Operators must be trained on the furnace's specific functions, including how to set the over-temperature limit correctly and how to operate the manual emergency shut-off.

Atmosphere Control Hazards

Many processes require controlled atmospheres using inert or reactive gases. In these cases, the gas delivery system is a critical part of the overall safety equation. A furnace's safety features do not typically monitor for gas leaks; that requires a separate, properly designed gas handling and leak detection system.

The Necessity of Regular Maintenance

Electronic components can fail and sensors can drift over time. Regular verification of the over-temperature protection system and sensor calibration (using the calibration offset feature) is not optional. It is a mandatory part of ensuring the safety systems will function when needed.

Making the Right Choice for Your Goal

When evaluating a vertical tube furnace, your specific application should guide which safety features you prioritize.

- If your primary focus is high-temperature processing (>1200°C): Prioritize a robust over-temperature protection system and a furnace tube material (like high-purity alumina) rated well above your maximum operating temperature.

- If your primary focus is operator safety and ease of use: Look for comprehensive self-diagnostic functions, clear alarm systems, and an intuitive, easily accessible emergency shut-off mechanism.

- If your primary focus is unattended or long-duration runs: Insist on features like auto-recovery after power failure, heater disconnection detection, and a reliable earth leakage breaker.

Ultimately, a safe furnace is one where electronic, material, and operational safety are treated as an interconnected system.

Summary Table:

| Safety Feature Type | Key Components | Purpose |

|---|---|---|

| Active Electronic | Over-temperature protection, Disconnection/short-circuit detection, Self-diagnostics, Earth leakage breaker | Automatically prevent hazards like thermal runaway and electrical faults |

| Passive Material | High-integrity furnace tubes (e.g., quartz, alumina), Vertical design with smaller footprint | Provide inherent protection against breaches and reduce lab risks |

| Operational | Manual emergency shut-off, Regular maintenance, Gas handling systems | Ensure safe usage and complement built-in features |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior protection and performance. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing