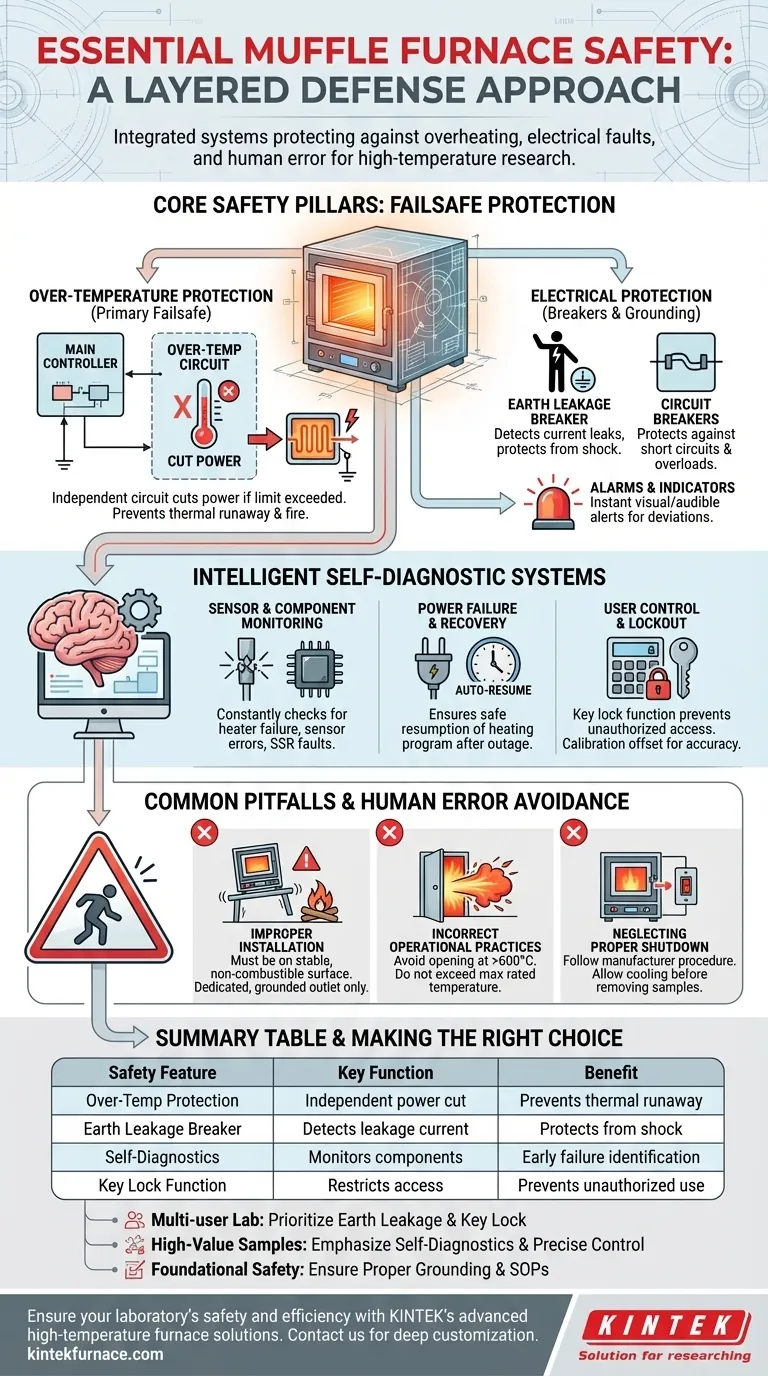

Beyond reaching extreme temperatures, the defining characteristic of a professional-grade muffle furnace is its integrated safety system. The most important safety features are those that protect against overheating, electrical faults, and component failure. These include independent over-temperature protection circuits, earth leakage circuit breakers, and comprehensive self-diagnostic functions that continuously monitor the furnace's health.

A truly safe muffle furnace operates on a principle of layered defense. It combines automated self-protection systems that prevent catastrophic failure with robust physical safeguards that protect the user, all of which must be supported by disciplined operational procedures.

Core Safety Pillars: From Overheating to Electrical Failure

A furnace's primary risks are extreme heat and high-voltage electricity. Modern designs address these with dedicated, redundant systems that function independently of the main temperature controller.

Over-Temperature Protection (The Primary Failsafe)

This is the most critical safety feature. It is a secondary, independent control circuit designed to cut power to the heating elements if the main controller fails and the temperature exceeds a user-set safety limit.

Without this, a single controller malfunction could lead to a thermal runaway event, destroying the furnace, the samples within it, and creating a severe fire hazard.

Electrical Protection (Circuit and Leakage Breakers)

An earth leakage breaker is essential for protecting personnel from electric shock. It instantly cuts power if it detects a small amount of current leaking to the furnace's chassis, which could happen if a wire becomes frayed or insulation fails.

Standard electrical circuit breakers protect the furnace's internal components and the building's electrical system from damage caused by short circuits or overloads, such as from a failing Solid State Relay (SSR) or heating element.

Alarms and Indicators

Clear visual and audible alarms are non-negotiable. These systems alert the operator immediately to any deviation from normal operation, such as an over-temperature condition or a sensor error. This allows for prompt intervention before a minor issue becomes a major failure.

The Role of Intelligent Self-Diagnostic Systems

Modern furnaces go beyond simple failsafes by incorporating microprocessors that actively monitor the system's health. These "smart" features provide an advanced layer of protection and prevent failures before they happen.

Sensor and Component Monitoring

The furnace's control system should constantly run diagnostics to check for critical component failures.

This includes detecting heater disconnection, sensor errors, and short circuits in the power control components like SSRs or triacs. A furnace that can report why it has shut down is infinitely safer and easier to troubleshoot.

Power Failure and Recovery

An auto-recovery function ensures that after an unexpected power outage, the furnace can resume its heating program safely once power is restored. This prevents damage to sensitive samples that require a specific, uninterrupted thermal profile.

User Control and Lockout Features

A key lock function is a simple but effective feature in a multi-user environment. It prevents unauthorized or untrained personnel from operating the furnace or changing critical settings on a validated heating program.

Calibration offset capabilities, while primarily for accuracy, also contribute to safety by ensuring the displayed temperature accurately reflects the real chamber temperature, preventing accidental overheating.

Common Pitfalls: Where Safety Features Meet Human Error

Even the most advanced furnace is only as safe as its operator and environment. The most common safety incidents arise not from feature failure, but from procedural mistakes.

Improper Installation and Environment

The furnace must be placed on a stable, non-combustible surface like a cement platform. It requires a dedicated, properly grounded power outlet with an appropriate fuse or breaker to prevent circuit overloads and ensure shock protection.

Crucially, the area must be completely free of flammable, explosive, or corrosive materials.

Incorrect Operational Practices

Never exceed the furnace's maximum rated temperature. Operating at the absolute maximum for extended periods can shorten the life of heating elements and refractory materials.

Avoid opening the door at very high temperatures (e.g., above 600°C) to prevent thermal shock to the door and chamber insulation, and to avoid exposing the operator to a blast of intense radiant heat.

Neglecting Proper Shutdown

After a cycle is complete, always allow the furnace to cool down significantly before removing samples. Following the manufacturer's shutdown procedure—which often involves turning off the heaters but leaving power on for the controller and fan—is vital for equipment longevity.

Making the Right Choice for Your Goal

When evaluating a muffle furnace, match its safety features to your primary application and work environment.

- If your primary focus is operator safety in a multi-user lab: Prioritize a model with an earth leakage breaker, clear alarms, and a key lock function to prevent unauthorized use.

- If your primary focus is protecting high-value samples and equipment: Emphasize comprehensive self-diagnostic functions (for sensors, SSRs, heaters) and a precise, independent over-temperature controller.

- If your primary focus is establishing a foundational safety protocol: Ensure proper grounding and installation on a dedicated circuit, and build strict Standard Operating Procedures (SOPs) around its use.

By understanding these integrated safety systems and operational requirements, you can ensure your high-temperature work is not only effective but fundamentally secure.

Summary Table:

| Safety Feature | Key Function | Benefit |

|---|---|---|

| Over-Temperature Protection | Independent circuit cuts power if temperature exceeds limit | Prevents thermal runaway and fire hazards |

| Earth Leakage Breaker | Detects current leakage and cuts power | Protects personnel from electric shock |

| Self-Diagnostic Systems | Monitors components like heaters and sensors | Identifies failures early for proactive maintenance |

| Alarms and Indicators | Provides visual/audible alerts for issues | Enables quick operator intervention |

| Key Lock Function | Restricts access to controls | Prevents unauthorized use in multi-user labs |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, integrating top-tier safety features for peace of mind. Contact us today to discuss how we can enhance your lab's performance and safety!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?