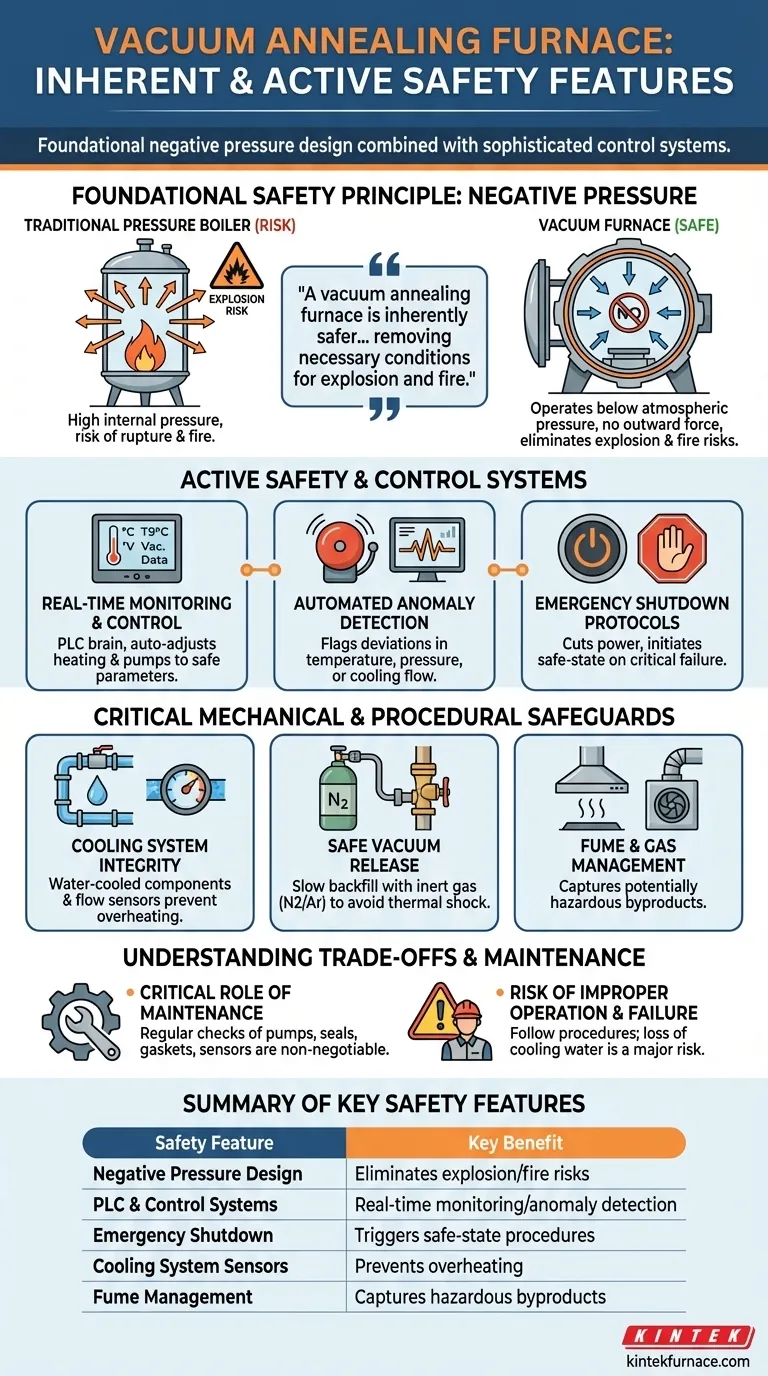

At their core, the safety features of a vacuum annealing furnace are designed around two principles: the inherent safety of operating in a vacuum and a sophisticated network of active control systems. By removing oxygen and operating at a negative pressure, these furnaces eliminate the common industrial risks of fire and explosion. This foundational safety is then reinforced by real-time monitoring systems that manage temperature, pressure, and cooling to prevent anomalies before they become hazards.

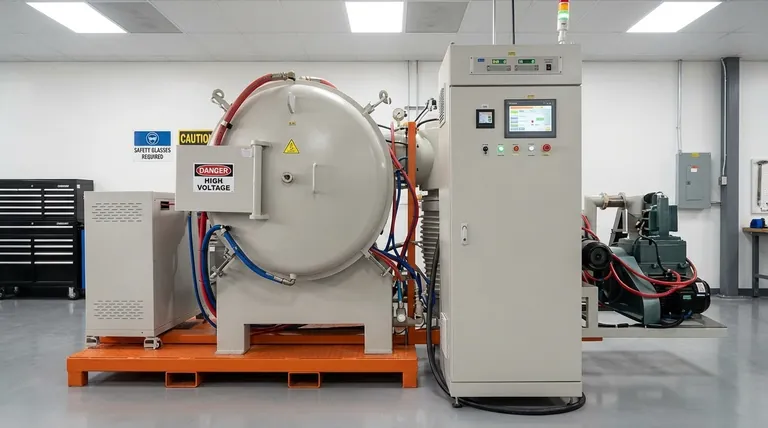

A vacuum annealing furnace is inherently safer than a conventional pressure or atmospheric furnace because its core operating principle—a vacuum—removes the necessary conditions for explosion and fire. Its advanced safety features are designed to maintain this controlled state and protect the equipment and operator.

The Foundational Safety Principle: Negative Pressure

The most significant safety feature of a vacuum furnace is not an add-on, but its fundamental design. Operating under negative pressure changes the entire risk profile compared to traditional heating equipment.

Elimination of Explosion Risk

Unlike a pressure boiler, which contains high internal pressure that can lead to a catastrophic rupture, a vacuum furnace operates at a pressure below the surrounding atmosphere. There is no outward force on the furnace walls, completely eliminating the risk of an explosion from over-pressurization.

Mitigation of Fire and Oxidation Risk

Fire requires oxygen. By evacuating the air from the heating chamber, a vacuum furnace removes the oxygen needed for combustion. This prevents the workpiece from oxidizing or catching fire, even at extreme temperatures, which is a critical safety and quality control feature.

Active Safety and Control Systems

Modern vacuum furnaces are equipped with intelligent systems that actively monitor and manage the entire annealing process, providing a robust layer of automated safety.

Real-Time Monitoring and Control

The furnace’s brain is typically a Programmable Logic Controller (PLC) paired with temperature and pressure controllers. This system provides real-time data on vacuum levels and temperature, automatically adjusting heating elements and pump activity to stay within precise, safe parameters.

Automated Anomaly Detection

These control systems are programmed to detect any deviation from the desired process. If the temperature overshoots, the vacuum level drops, or cooling water flow is interrupted, the system immediately flags the anomaly.

Emergency Shutdown Protocols

In the event of a critical anomaly, such as a cooling system failure, the furnace will trigger an emergency shutdown. This automatically cuts power to the heating elements and initiates other safe-state procedures to protect the equipment, the product, and personnel.

Critical Mechanical and Procedural Safeguards

Beyond the digital controls, physical engineering and established operating procedures are essential for ensuring safe, repeatable outcomes.

Cooling System Integrity

The furnace walls, door, and power feedthroughs are typically water-cooled to protect them from the intense internal heat. Cooling water flow sensors are a vital safety feature that will trigger an alarm or shutdown if the flow is insufficient, preventing furnace body overheating and damage.

Safe Vacuum Release

Returning the chamber to atmospheric pressure must be done correctly. A proper vacuum release procedure uses an inert gas like nitrogen or argon to backfill the chamber slowly, preventing thermal shock to the hot workpiece or contamination from ambient air.

Fume and Gas Management

For processes involving materials that may release volatile substances or fumes, some vacuum furnaces are equipped with fume hoods or local exhaust systems. This ensures any potentially hazardous byproducts are safely captured and vented, protecting operators and maintaining compliance.

Understanding the Trade-offs and Maintenance Needs

While inherently safe, the reliability of a vacuum furnace depends entirely on its condition and proper operation. Complacency is the greatest risk.

The Critical Role of Maintenance

The safety systems are only as good as the components they monitor. A regular maintenance schedule is non-negotiable. This includes inspecting and servicing vacuum pumps, checking door seals and gaskets, calibrating control systems, and verifying the function of all sensors. A leaking seal can compromise the vacuum, introducing risks the furnace is designed to prevent.

The Risk of Improper Operation

Operator error remains a potential hazard. Failing to follow correct procedures for loading, unloading, or backfilling can introduce risks. For this reason, modern furnaces often offer automatic or semi-automatic control modes to minimize manual intervention and ensure process consistency.

Cooling System Failure

The single most critical point of failure on a water-cooled vacuum furnace is the loss of cooling water. This can lead to rapid overheating of the furnace body, seal failure, and significant equipment damage. Reliable water sources and functional flow sensors are paramount.

Making the Right Choice for Your Goal

Understanding how these safety systems work together allows you to prioritize what matters most for your specific operational needs.

- If your primary focus is process stability and quality: The PLC and programmable controllers are your most important features, as they ensure precise, repeatable control over the vacuum and thermal environment.

- If your primary focus is operator safety and compliance: The fundamental negative-pressure design, combined with emergency shutdown systems and fume management, provides the highest level of protection.

- If your primary focus is long-term reliability and uptime: A rigorous preventive maintenance schedule for the vacuum pumps, seals, and cooling system is the key to preventing failures.

By leveraging its inherent design and intelligent controls, a well-maintained vacuum annealing furnace offers one of the safest and most controlled thermal processing environments available.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Negative Pressure Design | Eliminates explosion and fire risks by removing oxygen |

| PLC and Control Systems | Provides real-time monitoring and automated anomaly detection |

| Emergency Shutdown | Triggers safe-state procedures for critical failures |

| Cooling System Sensors | Prevents overheating by monitoring water flow |

| Fume Management | Captures hazardous byproducts for operator safety |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our solutions can protect your operations and boost performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity