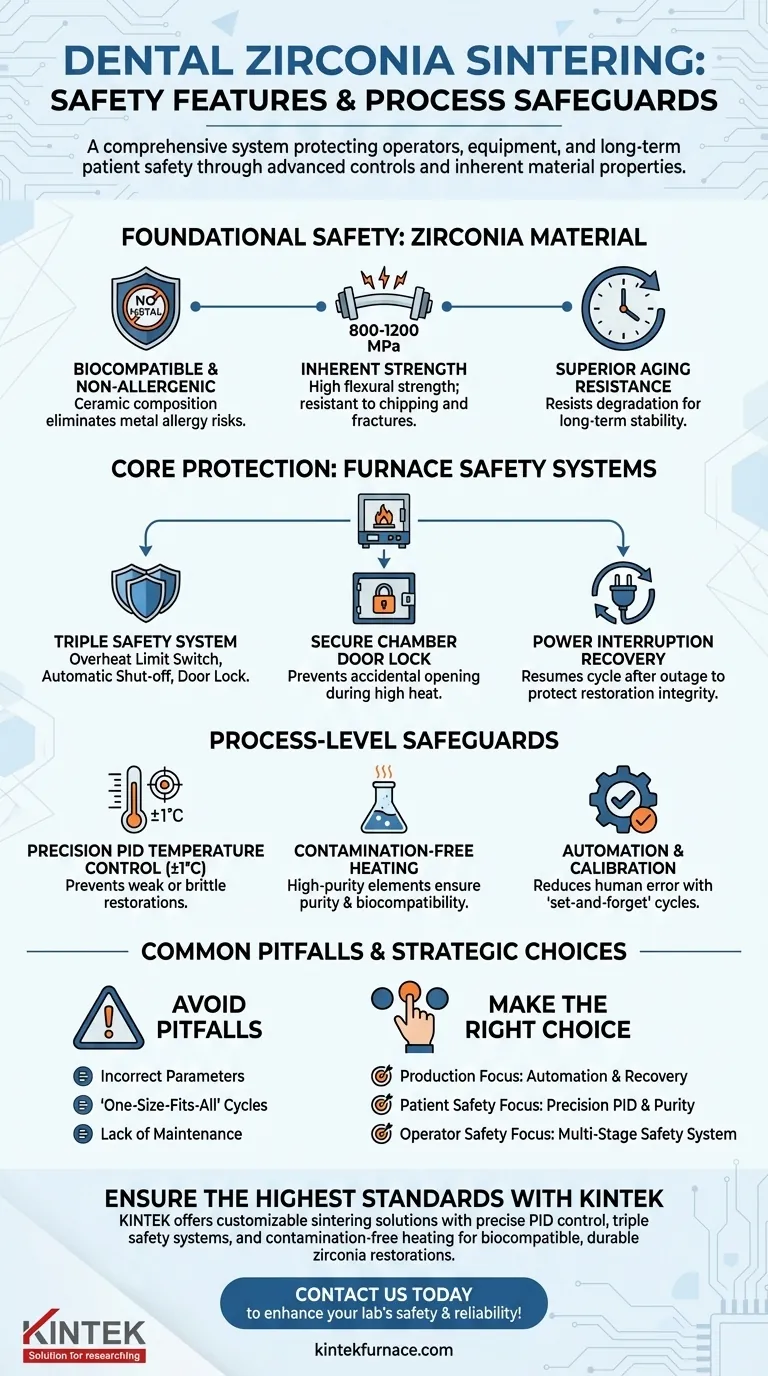

The primary safety features of the dental zirconia sintering process are a combination of advanced equipment controls and the inherent properties of the material itself. Furnaces are equipped with a triple safety system—including an overheating limit switch, a door lock, and an automatic shut-off—while the zirconia material is biocompatible, non-allergenic, and produces no harmful radiation.

The concept of safety in dental zirconia sintering extends beyond simple operator protection. It is a comprehensive system designed to ensure the integrity of the process, the reliability of the equipment, and the long-term clinical safety of the final restoration for the patient.

Foundational Safety: The Zirconia Material

The safety of the final product begins with the material. Dental zirconia is chosen not just for its aesthetics and strength but also for its fundamental biocompatibility, which protects the patient.

Biocompatibility and Allergen-Free Nature

Zirconia is a ceramic, not a metal. This composition completely eliminates the risk of metal allergies, a significant concern for some patients with traditional PFM (Porcelain-Fused-to-Metal) restorations.

Inherent Strength and Durability

Sintered zirconia possesses exceptionally high flexural strength, often between 800 and 1200 MPa. This incredible durability means the final crown or bridge is highly resistant to chipping, cracking, and fractures, ensuring long-term safety and stability in the patient's mouth.

Superior Aging Resistance

The material is engineered to effectively resist degradation over time. This unique stability prevents the material from becoming brittle or weak after years of use, safeguarding against unexpected failures.

The Core of Protection: Sintering Furnace Safety Systems

Modern sintering furnaces are not simply high-temperature ovens; they are sophisticated pieces of equipment with multiple overlapping systems designed to protect the operator, the lab environment, and the restoration itself.

Preventing Overheating and Failure

Most furnaces feature a triple safety system. A high-temperature limit switch acts as a primary fail-safe against overheating, while an automatic shut-off mechanism powers down the unit upon completion of a cycle, preventing a cycle from running indefinitely.

Securing the Sintering Chamber

A door lock mechanism is a critical operator safety feature. It prevents the furnace door from being opened accidentally during the extremely high-temperature sintering cycle, protecting the user from thermal hazards.

Ensuring Integrity After Power Loss

A power interruption recovery function allows the sintering process to resume exactly where it left off after a power outage. This isn't just a feature of convenience; it's a safety measure that prevents a batch of restorations from being compromised by an incomplete cycle.

Process-Level Safeguards for Precision and Reliability

Safety is also achieved through process control. Features that guarantee a precise and repeatable sintering cycle are essential for producing a clinically safe and effective dental restoration.

Precision Temperature Control

Modern furnaces use PID (Proportional-Integral-Derivative) intelligent temperature control systems. These maintain chamber temperatures with an accuracy of ±1℃, which is crucial. Deviations can result in under-sintered (weak) or over-sintered (brittle) restorations, both of which are clinical risks.

Contamination-Free Heating

High-purity dental silicon molybdenum heating elements are used to ensure pollution-free and even heat distribution. This prevents contaminants from being baked into the zirconia, maintaining the material's biocompatibility and aesthetic properties.

Automation to Reduce Human Error

Built-in automated software and calibration tools allow for "set-and-forget" sintering cycles. By reducing manual input, these systems minimize the risk of human error in programming a cycle, leading to more consistent and reliable outcomes.

Common Pitfalls to Avoid

While the technology is inherently safe, its effectiveness depends entirely on correct operation. Understanding these potential issues is key to maintaining a safe and reliable workflow.

The Criticality of Correct Parameters

The most advanced safety features cannot compensate for incorrect programming. Using the wrong sintering cycle (temperature, duration, or ramp rate) for a specific type of zirconia is the most common cause of a compromised restoration, leading to clinical failure.

The Myth of "One-Size-Fits-All" Sintering

Different zirconia materials, such as high-translucency for anterior crowns and high-strength for bridges, require distinct sintering profiles. Applying a generic "fast" cycle to a material not designed for it can severely impact its final strength and aesthetics.

Maintenance is Non-Negotiable

The precision of the furnace relies on its components. Temperature sensors and heating elements require periodic calibration and maintenance as specified by the manufacturer. A slow drift in temperature accuracy can silently compromise every restoration that passes through the furnace.

Making the Right Choice for Your Goal

Selecting equipment and defining protocols should be driven by your primary objectives.

- If your primary focus is high-volume production: Prioritize furnaces with robust automation, power interruption recovery, and the capacity to store dozens of programs to ensure consistency and minimize error across many users and cases.

- If your primary focus is ultimate patient safety: Scrutinize the specifications for PID temperature control (±1℃ accuracy) and contamination-free heating elements to guarantee the material's integrity and biocompatibility.

- If your primary focus is operator safety and ease of use: Confirm the presence of a multi-stage safety system, including a secure door lock, automatic shut-off, and an intuitive user interface to reduce operational risk.

Ultimately, understanding that these safety features work together as a system empowers you to produce reliable, durable, and biocompatible restorations with confidence.

Summary Table:

| Safety Feature | Purpose | Benefit |

|---|---|---|

| Triple Safety System (Overheat Limit, Door Lock, Auto Shut-off) | Protects operator and equipment | Prevents accidents and overheating |

| Biocompatible Zirconia Material | Ensures patient safety | Eliminates allergy risks and provides long-term stability |

| PID Temperature Control (±1℃) | Maintains precise sintering conditions | Prevents weak or brittle restorations |

| Power Interruption Recovery | Resumes cycle after outage | Protects restoration integrity from incomplete cycles |

Ensure the highest safety standards for your dental lab and patients with KINTEK's advanced sintering solutions.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our sintering furnaces feature precise PID control, triple safety systems, and contamination-free heating to guarantee biocompatible, durable zirconia restorations.

Contact us today to discuss your lab's requirements and enhance your sintering process safety and reliability!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations