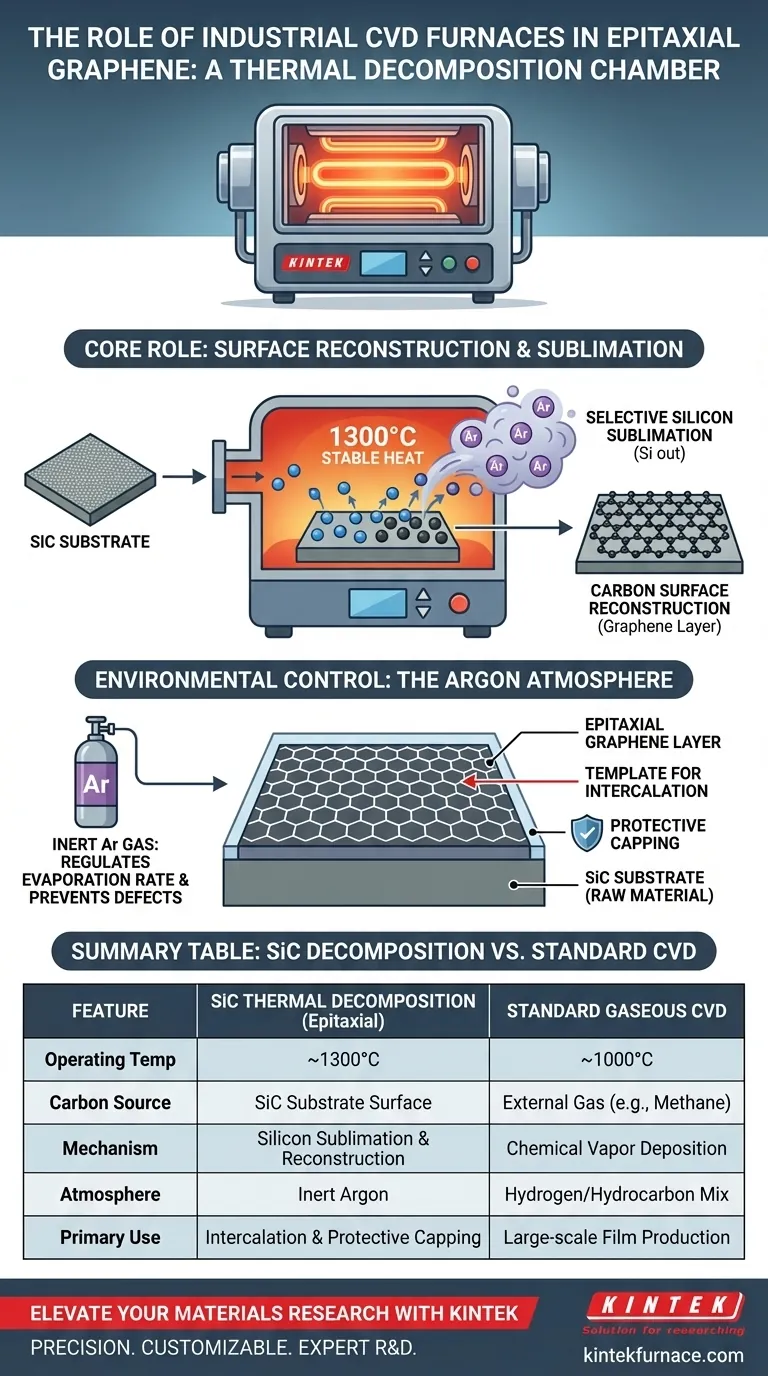

The industrial-grade CVD furnace functions as a high-precision thermal decomposition chamber rather than a standard deposition tool in this context. Specifically for epitaxial graphene, the furnace heats Silicon Carbide (SiC) substrates to approximately 1300°C in an argon atmosphere to induce the controlled sublimation of silicon atoms, leaving behind a carbon-rich surface.

The core role of the furnace is to facilitate surface reconstruction by removing silicon atoms from the substrate lattice. This creates a high-quality, large-area epitaxial graphene layer that serves as a robust template for atomic intercalation and a protective shield against oxidation.

The Mechanism of Thermal Decomposition

Precise High-Temperature Control

The production of epitaxial graphene on SiC requires temperatures significantly higher than standard CVD processes.

The furnace must maintain a stable environment of approximately 1300°C.

This extreme heat is the catalyst that breaks the chemical bonds within the silicon carbide substrate.

Selective Sublimation

Unlike standard CVD which introduces carbon gases (like methane) to deposit a layer, this process utilizes the substrate itself as the source material.

The furnace heat causes silicon atoms to sublime (evaporate) from the surface.

Because carbon has a lower vapor pressure, the carbon atoms remain on the surface rather than evaporating with the silicon.

Surface Reconstruction

Once the silicon atoms are removed, the remaining carbon atoms are unstable in their previous configuration.

The furnace environment allows these atoms to undergo surface reconstruction.

They naturally rearrange themselves into the hexagonal lattice structure characteristic of high-quality epitaxial graphene.

Environmental Control and Atmosphere

The Role of Argon

The primary reference highlights the use of an argon atmosphere within the furnace.

This inert gas environment is critical for regulating the rate of silicon evaporation.

Without this atmospheric control, the silicon might sublime too rapidly or unevenly, leading to defects in the graphene layer.

Creating a Functional Template

The resulting graphene is not just a passive coating; it interacts with the substrate and future layers.

It functions as a template for gallium atom intercalation, allowing for the modification of electronic properties.

Additionally, this epitaxial layer acts as a protective capping layer, shielding the material underneath from oxidation.

Understanding the Trade-offs

Process Intensity vs. Standard CVD

It is important to distinguish this epitaxial process from standard CVD growth on copper foil.

Standard CVD (referenced in supplementary materials) typically operates at lower temperatures (around 1000°C) and uses external gases like methane as a carbon source.

The epitaxial SiC process requires higher energy inputs (1300°C) and relies on the costly consumption of the SiC substrate's surface, rather than inexpensive gaseous carbon.

Substrate Dependency

The quality of the graphene is intrinsically linked to the quality of the SiC substrate.

In standard CVD, the copper foil is merely a catalyst; in this process, the substrate is the raw material.

Any defects in the underlying SiC crystal can propagate into the graphene layer during the reconstruction phase.

Making the Right Choice for Your Goal

When selecting a preparation method for graphene, consider your specific application requirements:

- If your primary focus is creating a template for intercalation: Utilize the high-temperature SiC decomposition method to ensure a structurally aligned epitaxial interface.

- If your primary focus is oxidation resistance: Rely on the SiC-derived epitaxial layer to serve as an integrated protective cap for the underlying material.

- If your primary focus is minimizing thermal budget: Consider standard gaseous CVD methods (like methane on copper) which operate at significantly lower temperatures (1000°C).

By controlling silicon sublimation at 1300°C, the CVD furnace transforms the substrate itself into a high-performance electronic material.

Summary Table:

| Feature | SiC Thermal Decomposition (Epitaxial) | Standard Gaseous CVD |

|---|---|---|

| Operating Temp | ~1300°C | ~1000°C |

| Carbon Source | SiC Substrate Surface | External Gas (e.g., Methane) |

| Mechanism | Silicon Sublimation & Reconstruction | Chemical Vapor Deposition |

| Atmosphere | Inert Argon | Hydrogen/Hydrocarbon Mix |

| Primary Use | Intercalation & Protective Capping | Large-scale Film Production |

Elevate Your Materials Research with KINTEK

Precision is paramount when managing high-temperature silicon sublimation. KINTEK provides industry-leading CVD systems, Muffle, and Vacuum furnaces designed to maintain the rigorous 1300°C stability required for flawless epitaxial graphene growth.

Backed by expert R&D and specialized manufacturing, our equipment is fully customizable to meet your unique laboratory or industrial needs. Whether you are performing atomic intercalation or developing oxidation-resistant templates, KINTEK delivers the thermal control you need to succeed.

Ready to optimize your graphene synthesis? Contact our technical experts today to find the perfect furnace solution for your application.

Visual Guide

References

- Emanuele Pompei, Stefano Veronesi. Novel Structures of Gallenene Intercalated in Epitaxial Graphene. DOI: 10.1002/smll.202505640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility