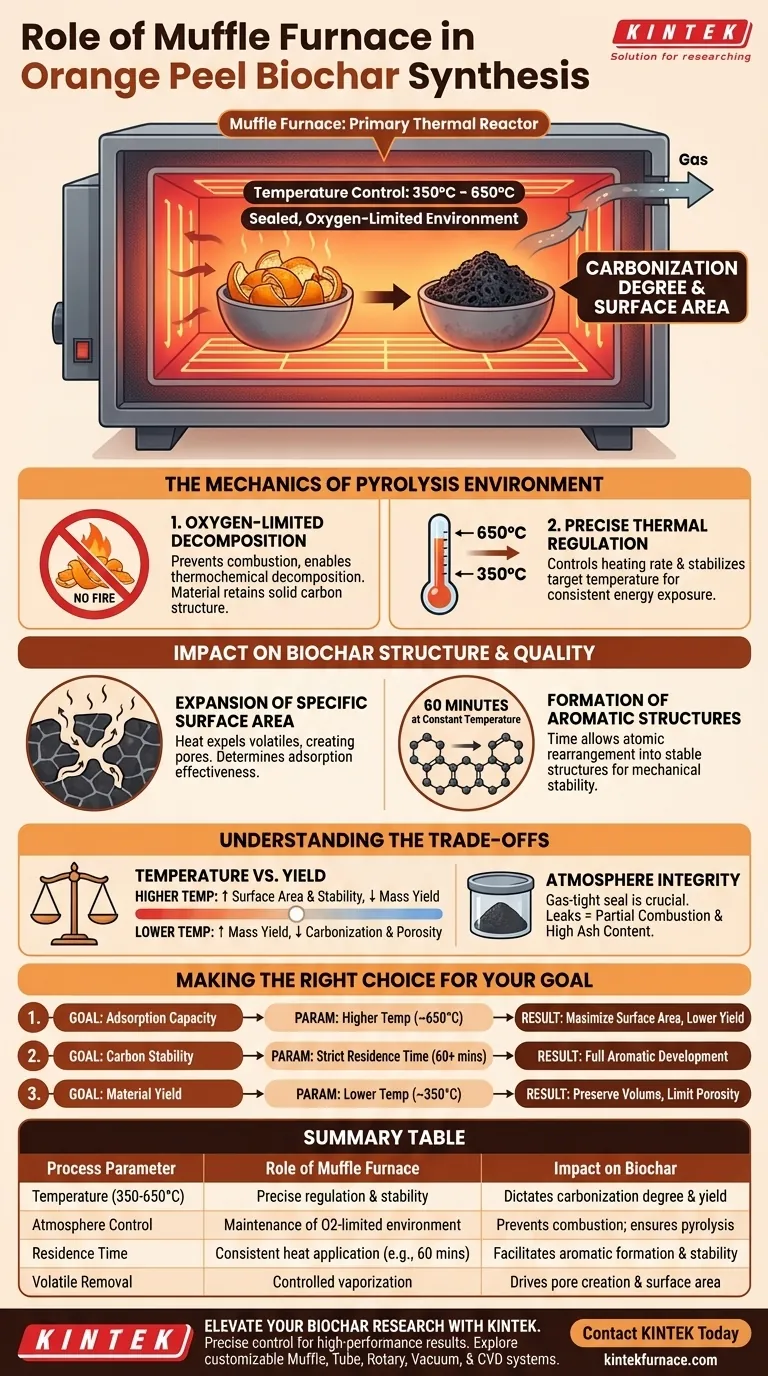

The muffle furnace acts as the primary thermal reactor for converting orange peel biomass into biochar through high-temperature pyrolysis. By providing a sealed, temperature-controlled environment typically between 350°C and 650°C, it facilitates thermochemical decomposition under oxygen-limited conditions to establish the material's carbon structure.

Core Takeaway: The muffle furnace is not merely a heat source; it is a precision instrument that dictates the carbonization degree and surface area of the biochar. Its ability to maintain a constant temperature for a specific duration (e.g., 60 minutes) allows for the controlled transformation of raw biomass into a stable, porous carbon skeleton without incinerating it.

The Mechanics of the Pyrolysis Environment

Oxygen-Limited Decomposition

The most critical function of the muffle furnace is to enable pyrolysis rather than combustion. By creating a sealed or semi-sealed environment, the furnace restricts oxygen availability during heating.

This hypoxic state ensures that the orange peel undergoes thermochemical decomposition instead of burning into ash. This process allows the organic material to break down chemically while retaining its solid carbon structure.

Precise Thermal Regulation

For orange peel synthesis, the furnace must maintain specific temperatures, generally ranging from 350°C to 650°C.

The equipment controls the heating rate and stabilizes the target temperature, ensuring the biomass is exposed to consistent thermal energy. This consistency is vital for reproducible results across different batches of biochar.

Impact on Biochar Structure and Quality

Expansion of Specific Surface Area

The heat provided by the furnace drives the expansion of the material's surface area.

As the temperature rises, volatile components are expelled, creating pores and voids within the biochar. This porosity is the primary determinant of the biochar's effectiveness in adsorption applications.

Formation of Aromatic Structures

The duration of the heating process plays a significant role in chemical stability.

Maintaining a constant temperature for 60 minutes allows the carbon atoms to rearrange into stable aromatic structures. This structural evolution determines the "carbonization degree" and the mechanical stability of the final product.

Removal of Volatiles

The furnace facilitates the efficient removal of non-carbon elements and volatile organic compounds.

By sustaining high temperatures, the furnace ensures these components are vaporized and exited from the material matrix. This leaves behind a fixed carbon skeleton that serves as the foundation for the biochar's functional properties.

Understanding the Trade-offs

Temperature vs. Yield

There is an inherent trade-off between the processing temperature and the final yield of the biochar.

Higher temperatures generally increase the surface area and carbon stability (aromaticity) but significantly reduce the total mass yield as more material is volatilized. Conversely, lower temperatures may result in higher yields but incomplete carbonization and lower surface area.

Atmosphere Integrity

While the muffle furnace provides the heat, the "oxygen-limited" aspect relies heavily on the integrity of the containment (e.g., a gas-tight retort or covered crucible inside the furnace).

If the containment within the furnace leaks or the furnace seal is compromised, oxygen ingress will lead to partial combustion. This degrades the pore structure and results in high ash content rather than high-quality carbon.

Making the Right Choice for Your Goal

To optimize the synthesis of orange peel biochar, you must adjust the furnace parameters based on your specific end-goal.

- If your primary focus is Adsorption Capacity: Prioritize higher temperatures (near 650°C) to maximize the specific surface area and pore volume, accepting a lower mass yield.

- If your primary focus is Carbon Stability: Ensure the residence time is strictly maintained (at least 60 minutes) to allow full development of aromatic structures.

- If your primary focus is Material Yield: Operate at the lower end of the temperature spectrum (closer to 350°C) to preserve biomass volume, though this may limit porosity.

The muffle furnace is the tool that translates your specific engineering requirements into the physical architecture of the carbon material.

Summary Table:

| Process Parameter | Role of Muffle Furnace | Impact on Biochar |

|---|---|---|

| Temperature (350-650°C) | Precise thermal regulation and stability | Dictates carbonization degree and yield |

| Atmosphere Control | Maintenance of oxygen-limited environment | Prevents combustion; ensures pyrolysis over incineration |

| Residence Time | Consistent heat application (e.g., 60 mins) | Facilitates aromatic structure formation and stability |

| Volatile Removal | Controlled vaporization of non-carbon elements | Drives pore creation and surface area expansion |

Elevate Your Biochar Research with KINTEK

Precise carbonization requires more than just heat—it demands absolute control. At KINTEK, we specialize in high-performance thermal solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are synthesizing orange peel biochar or advanced carbon structures, our lab furnaces are fully customizable to meet your specific temperature and atmospheric requirements.

Backed by expert R&D and manufacturing, we provide the tools you need for reproducible, high-quality results.

Contact KINTEK Today to Customize Your Furnace

Visual Guide

References

- Mariana Paola Cabrini, Claudinei Fonseca Souza. Biochar from orange waste as a filter medium for domestic effluent treatment aimed at agricultural reuse. DOI: 10.4136/ambi-agua.3024

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature box resistance furnace contribute to TWIP steel homogenization? Master Chemical Uniformity

- How should samples be placed inside the muffle furnace? Ensure Uniform Heating and Safety

- What is the role of precise temperature gradient control in a high-temperature box furnace? Master Mo6S8 Synthesis

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- What PPE is necessary when adjusting controls or handling equipment during furnace operation? Essential Safety Gear for High-Temperature Tasks

- What are some specific applications of muffle furnaces? Unlock Precision in Heat Treatment and Analysis

- What are the primary applications of a muffle furnace? Essential for Analysis and Heat Treatment

- What role does a muffle furnace play in mango seed moisture analysis? Ensure Precise Baselines for Drying Kinetics