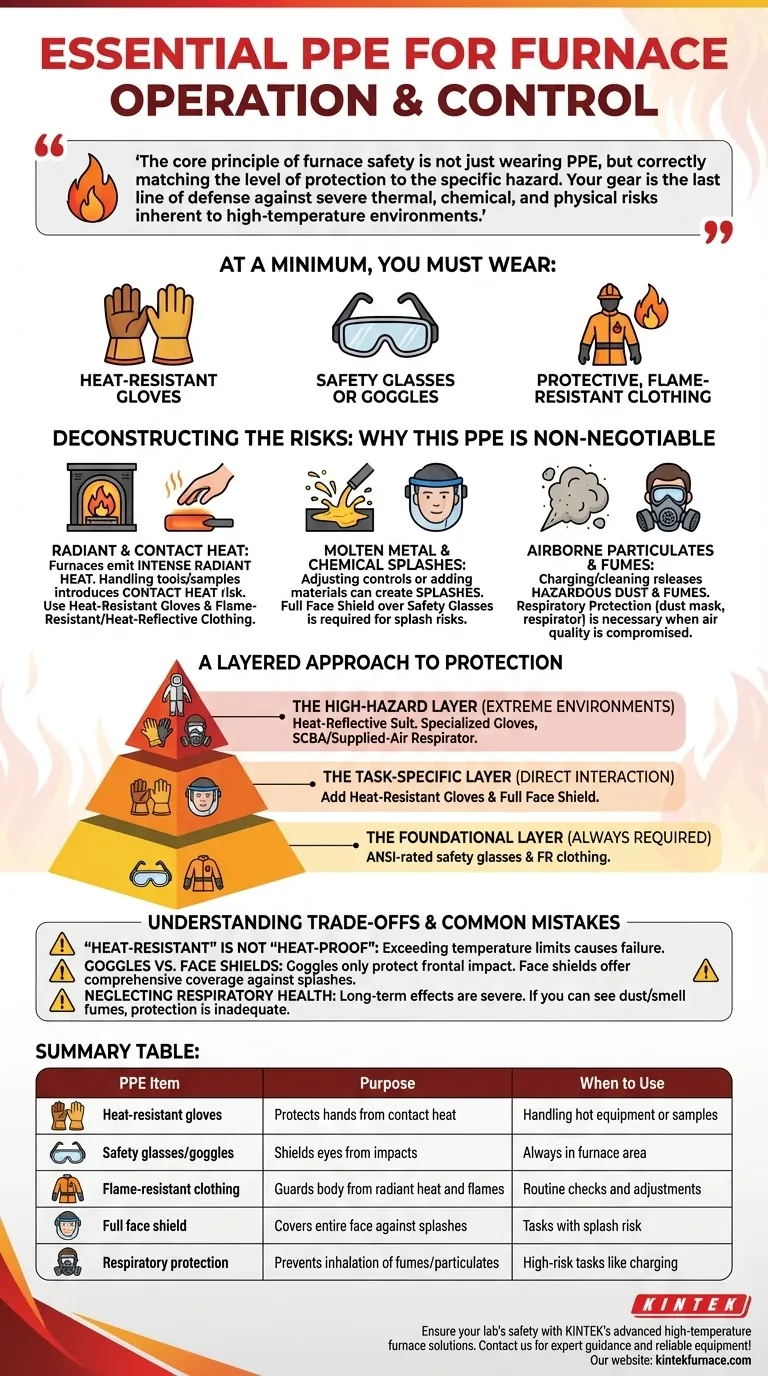

At a minimum, you must wear heat-resistant gloves, safety glasses or goggles, and protective, flame-resistant clothing when adjusting controls or handling equipment during furnace operation. For tasks with a higher risk of splashes or airborne particles, a face shield and appropriate respiratory protection are also essential.

The core principle of furnace safety is not just wearing PPE, but correctly matching the level of protection to the specific hazard. Your gear is the last line of defense against severe thermal, chemical, and physical risks inherent to high-temperature environments.

Deconstructing the Risks: Why This PPE is Non-Negotiable

Understanding the specific dangers of a furnace environment clarifies why each piece of PPE is critical. The goal is to create a complete barrier between you and potential harm.

Radiant and Contact Heat

Furnaces emit intense radiant heat that can cause burns even without direct contact. Handling tools, samples, or equipment introduces the additional risk of contact heat.

Heat-resistant gloves are your primary defense for handling hot objects. Flame-resistant (FR) or heat-reflective clothing protects your body from both ambient heat and potential flashes.

Molten Metal and Chemical Splashes

Adjusting controls or adding materials can create splashes of molten metal, slag, or chemicals. A single drop can cause a devastating burn or eye injury.

Safety glasses or goggles provide a baseline level of eye protection. However, for any task with a splash risk, a full face shield worn over safety glasses is the required standard, protecting the entire face.

Airborne Particulates and Fumes

Charging materials, cleaning dross, or performing maintenance can release hazardous dust, particulates, and chemical fumes into the air. These hazards are often invisible.

Respiratory protection, such as a dust mask or a fitted respirator, is necessary when the air quality is compromised. The specific type of respirator depends on the materials being processed and the contaminants they produce.

A Layered Approach to Protection

Think of your PPE in layers, with each layer corresponding to an increasing level of risk.

The Foundational Layer (Always Required)

This is the absolute minimum for anyone in the furnace area, even for observation. It includes ANSI-rated safety glasses and long-sleeved, natural-fiber or flame-resistant protective clothing.

The Task-Specific Layer (Direct Interaction)

When you are directly interacting with the furnace—adjusting controls, opening doors, or handling tools—you must add this layer. It consists of heat-resistant gloves and a full face shield.

The High-Hazard Layer (Extreme Environments)

For high-risk tasks like charging, tapping, or emergency maintenance, you need maximum protection. This includes a full heat-reflective or aluminized suit, specialized high-temperature gloves, and a self-contained breathing apparatus (SCBA) or supplied-air respirator.

Understanding the Trade-offs and Common Mistakes

Selecting the right PPE is only the first step. Understanding its limitations is just as important.

"Heat-Resistant" Is Not "Heat-Proof"

Gloves and clothing are rated for specific temperatures and contact times. Exceeding these limits will result in equipment failure and injury. Always know the rating of your gear and avoid prolonged contact with hot surfaces.

Goggles vs. Face Shields: A Critical Distinction

Safety glasses protect from frontal impact, but they offer little defense against a splash from below or the side. A face shield provides comprehensive coverage for the entire face and is the only acceptable primary protection against splashes.

Neglecting Respiratory Health

The long-term health effects of inhaling metal fumes and particulates are severe. The danger is not always immediate or obvious, making respiratory protection one of the most commonly overlooked safety requirements. If you can see dust or smell fumes, your protection is inadequate.

Matching Your PPE to the Task

Use this guide to select the appropriate level of protection for your specific activity.

- If your primary focus is routine checks or adjusting controls at a distance: Ensure you are wearing the foundational layer of safety glasses and flame-resistant clothing.

- If your primary focus is handling hot equipment or taking samples: You must add the task-specific layer of heat-resistant gloves and a full face shield.

- If your primary focus is charging, tapping, or performing furnace maintenance: You must use the high-hazard layer, including specialized clothing and appropriate respiratory protection.

Ultimately, disciplined and proactive safety is a non-negotiable part of professional furnace operation.

Summary Table:

| PPE Item | Purpose | When to Use |

|---|---|---|

| Heat-resistant gloves | Protects hands from contact heat | Handling hot equipment or samples |

| Safety glasses/goggles | Shields eyes from impacts | Always in furnace area |

| Flame-resistant clothing | Guards body from radiant heat and flames | Routine checks and adjustments |

| Full face shield | Covers entire face against splashes | Tasks with splash risk |

| Respiratory protection | Prevents inhalation of fumes/particulates | High-risk tasks like charging |

Ensure your lab's safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today for expert guidance and reliable equipment!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals