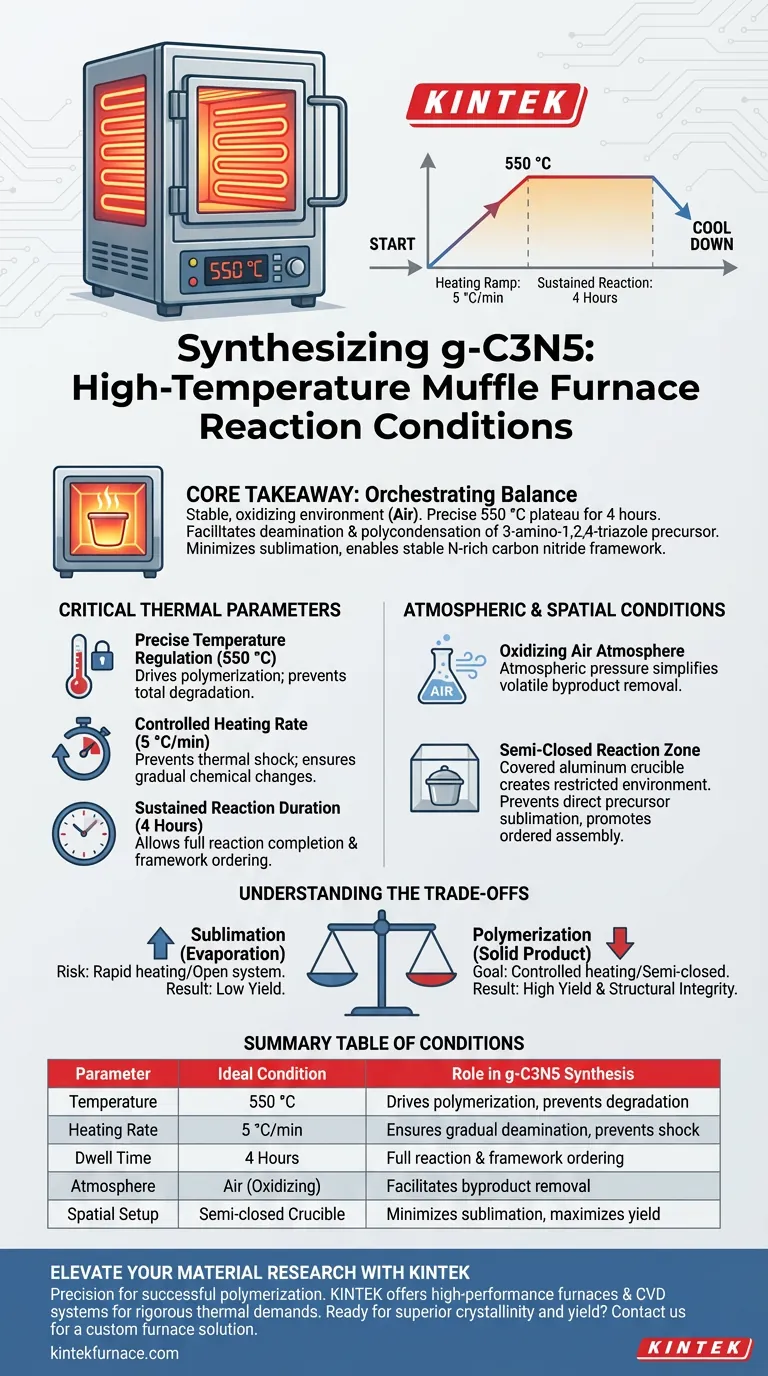

A high-temperature muffle furnace establishes a stable, oxidizing thermal environment characterized by a precise temperature plateau of 550 °C maintained for 4 hours in an air atmosphere. This controlled heating process, typically driven by a ramp rate of 5 °C/min, facilitates the necessary deamination and polycondensation of the 3-amino-1,2,4-triazole precursor to synthesize the g-C3N5 semiconductor.

Core Takeaway The muffle furnace does not simply heat the material; it orchestrates a delicate balance between thermal decomposition and structural assembly. By providing a uniform thermal field and allowing for a semi-closed reaction environment, it enables the transformation of organic precursors into a stable, nitrogen-rich carbon nitride framework while minimizing material loss through sublimation.

The Critical Thermal Parameters

Precise Temperature Regulation

The synthesis of g-C3N5 requires a specific thermal "sweet spot." The muffle furnace must maintain a stable reaction temperature of 550 °C.

This temperature is high enough to drive the polymerization reaction but low enough to prevent the total thermal degradation of the carbon nitride structure.

Controlled Heating Rate

The transition to the target temperature is just as critical as the final plateau. The furnace is programmed with a heating rate of approximately 5 °C/min.

A controlled ramp prevents thermal shock and ensures that the precursor undergoes gradual chemical changes rather than rapid, chaotic decomposition.

Sustained Reaction Duration

Once the target temperature is reached, the furnace maintains this environment for a continuous period of 4 hours.

This duration ensures the chemical reaction reaches completion, allowing time for the full deamination of the precursor and the ordering of the triazole units into a robust framework.

Atmospheric and Spatial Conditions

Oxidizing Air Atmosphere

Unlike syntheses requiring inert gases like argon or nitrogen, this process is conducted in an air atmosphere.

The muffle furnace allows the reaction to proceed under normal atmospheric pressure, which simplifies the removal of volatile byproducts generated during the condensation process.

Semi-Closed Reaction Zone

While the furnace provides the heat, the reaction often takes place within a covered aluminum crucible placed inside the chamber.

This setup creates a locally restricted, semi-closed environment. It prevents the direct sublimation (evaporation) of the 3-amino-1,2,4-triazole precursor before it can polymerize.

Retention of Intermediates

The semi-closed environment helps maintain a high concentration of reaction intermediates.

This promotes the ordered assembly of the nitrogen-rich framework, directly influencing the yield and the crystalline quality of the final photocatalyst.

Understanding the Trade-offs

Sublimation vs. Polymerization

The primary challenge in this solid-phase synthesis is the competition between the precursor reacting to form the solid product and the precursor simply evaporating.

If the furnace heats too rapidly or if the system is entirely open, the precursor may sublime, resulting in extremely low yields.

Thermal Homogeneity

The quality of the final g-C3N5 depends heavily on the uniformity of the thermal field provided by the furnace.

Uneven heating can lead to variations in crystallinity across the sample, resulting in inconsistent photocatalytic performance (visible light absorption) within the same batch.

Making the Right Choice for Your Goal

To maximize the efficiency of your g-C3N5 synthesis, align your furnace setup with your specific objectives:

- If your primary focus is High Yield: Ensure you utilize a covered crucible setup within the furnace to create a semi-closed environment that traps intermediates and reduces sublimation loss.

- If your primary focus is Structural Integrity: Adhere strictly to the 5 °C/min ramp rate and 550 °C hold time to allow for gradual, orderly deamination and polymerization without thermal shock.

Success in synthesizing g-C3N5 relies not just on reaching high temperatures, but on the precise control of the heating profile and the containment of the reaction atmosphere.

Summary Table:

| Parameter | Ideal Condition | Role in g-C3N5 Synthesis |

|---|---|---|

| Temperature | 550 °C | Drives polymerization while preventing thermal degradation |

| Heating Rate | 5 °C/min | Ensures gradual deamination and prevents thermal shock |

| Dwell Time | 4 Hours | Allows full reaction completion and framework ordering |

| Atmosphere | Air (Oxidizing) | Facilitates byproduct removal at atmospheric pressure |

| Spatial Setup | Semi-closed Crucible | Minimizes precursor sublimation and maximizes yield |

Elevate Your Material Research with KINTEK

Precision is the difference between successful polymerization and material loss. KINTEK provides high-performance Muffle, Tube, Rotary, and Vacuum furnaces, alongside specialized CVD systems, designed to meet the rigorous thermal demands of photocatalyst synthesis.

Backed by expert R&D and world-class manufacturing, our lab high-temp furnaces are fully customizable to your unique research needs, ensuring uniform thermal fields and stable reaction environments for your most sensitive precursors.

Ready to achieve superior crystallinity and yield? Contact us today to find your custom furnace solution.

Visual Guide

References

- Improving Photocatalytic Hydrogen Production over Pd Nanoparticles Decorated with g-C3N5 Photocatalyst. DOI: 10.3390/pr13010235

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the disadvantages of muffle furnace? Understanding the Trade-offs of Indirect Heating

- What are the primary applications of a muffle furnace in laboratories? Achieve Precise High-Temperature Processing

- Why is heat treatment in a muffle furnace required for bioactive glass pellets? Ensure Sterile Biological Testing

- Why is the muffle furnace widely used in the industrial sector? Achieve Clean, Precise High-Temperature Processing

- Why is a muffle furnace used without protective gases for molybdenum alloys? Simulate Real-World Oxidation Conditions

- Why are box furnaces considered essential in various industries? Discover Their Versatile Heating Solutions

- What role does a muffle furnace play in the carbonization synthesis of orange peel biochar? Precision Thermal Pyrolysis

- How is a high-temperature box furnace utilized during the calcination and sintering stages of SrVO3 precursors?