In a laboratory setting, a muffle furnace is primarily used for high-temperature processes that demand precise thermal control and an environment free from contaminants. Its core applications include analytical ashing to determine the inorganic content of a sample, heat treatment to alter the physical properties of metals, and materials research for synthesizing or testing substances like ceramics and glass.

The defining feature of a muffle furnace is its internal chamber—the "muffle"—which isolates the sample from the heating elements and any combustion byproducts. This separation makes it the essential tool for applications where chemical purity and precise, uniform heating are non-negotiable.

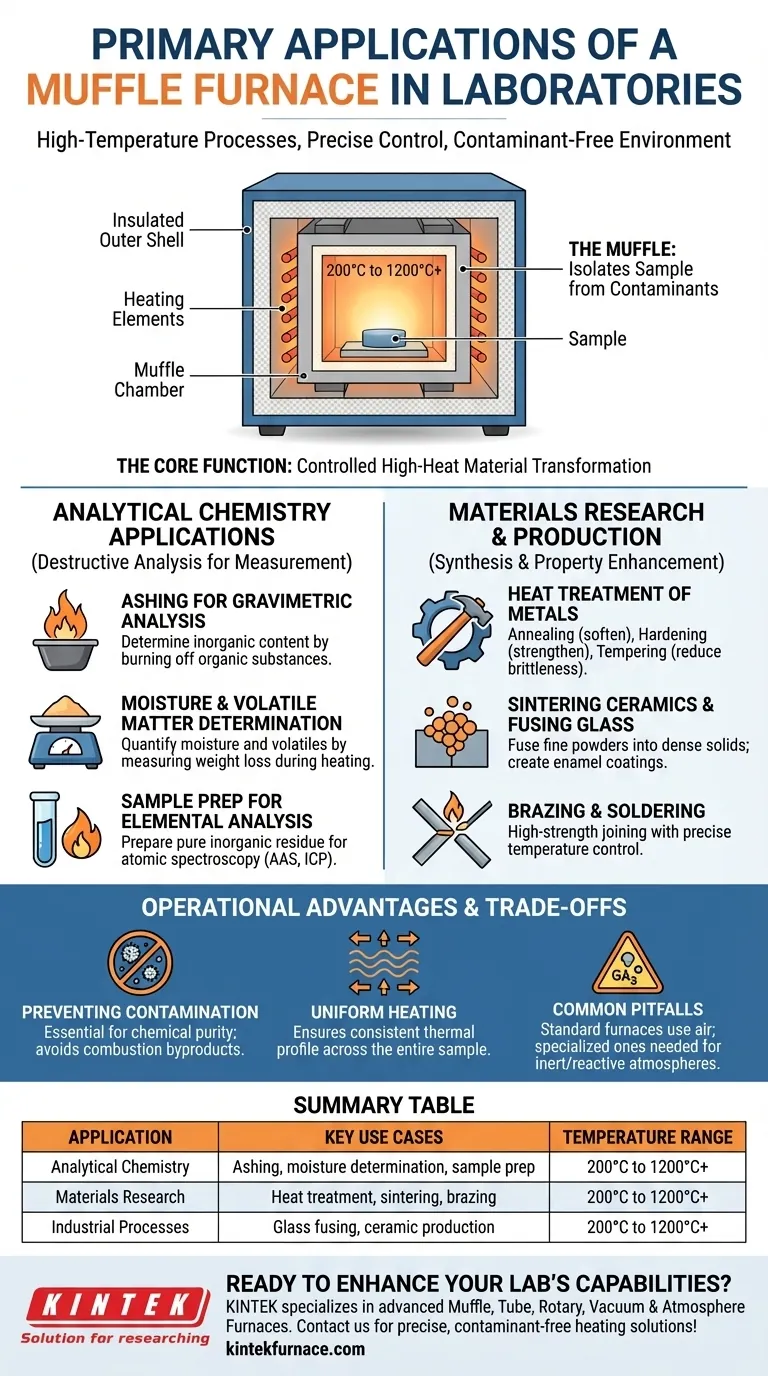

The Core Function: High-Heat Material Transformation

A muffle furnace is not just an oven; it is a controlled environment for fundamentally changing or analyzing materials at extreme temperatures, typically ranging from 200°C to over 1200°C.

What the "Muffle" Achieves

The term "muffle" refers to the insulated inner chamber that protects the sample. Unlike a simple kiln where combustion gases might interact with the material, the muffle acts as a radiant heat box.

This design ensures that heat is transferred cleanly and uniformly, without introducing chemical contaminants from the heating source.

The Importance of Precision

Modern muffle furnaces offer programmable digital controllers that allow for precise temperature ramping, holding (soaking), and cooling cycles. This control is critical for achieving repeatable results in both material synthesis and analysis.

Key Applications in Analytical Chemistry

Much of a muffle furnace's work involves breaking down materials to understand their composition. This is a form of destructive analysis where the goal is measurement.

Ashing for Gravimetric Analysis

This is one of the most common applications. A sample (such as food, polymers, or biological tissue) is heated to a high temperature to burn off all organic and volatile substances.

The non-combustible material that remains, known as ash, is then weighed. This process is crucial for determining the mineral or filler content in a sample.

Determining Moisture and Volatile Matter

By heating a sample at specific temperatures for set durations, a muffle furnace can be used to drive off moisture and other volatile compounds. The weight loss is measured at each step to quantify these components.

Sample Preparation for Elemental Analysis

After ashing, the remaining inorganic residue is often dissolved in acid and analyzed by techniques like atomic absorption spectroscopy (AAS) or inductively coupled plasma (ICP). The furnace provides the first critical step in preparing a pure inorganic sample for these sensitive instruments.

Transforming Materials in Research and Production

Beyond analysis, muffle furnaces are workhorses for creating and modifying materials. Here, the goal is synthesis or property enhancement.

Heat Treatment of Metals

Metallurgists use muffle furnaces for processes like annealing (softening metal and improving ductility), hardening (increasing strength), and tempering (reducing brittleness). The uniform, contaminant-free heat is essential for achieving the desired metallic crystal structure.

Sintering Ceramics and Fusing Glass

Ceramics are often formed from fine powders that are heated just below their melting point. In the furnace, the particles fuse together in a process called sintering to create a dense, solid object.

Similarly, the furnace provides the controlled, clean environment needed to fuse glass powders or create enamel coatings on metal or ceramic substrates.

Brazing and Soldering

For high-strength joining of metals, brazing requires precise temperature control to melt a filler metal into a joint. A muffle furnace provides the necessary heat in a controlled atmosphere, preventing oxidation that could weaken the bond.

Understanding the Operational Advantages and Trade-offs

Choosing a muffle furnace over other heating methods comes down to a few key considerations.

The Primary Advantage: Preventing Contamination

If your process is sensitive to chemical changes from external gases, a muffle furnace is required. A direct-fired furnace would expose your sample to the byproducts of combustion, altering its chemistry.

The Benefit of Uniformity

The radiant heat inside a muffle chamber tends to be more uniform than direct heating methods. This prevents hot spots and ensures the entire sample experiences the same thermal profile, which is critical for consistent material properties.

Common Pitfalls to Avoid

A standard muffle furnace operates with a normal air atmosphere. If your process requires an inert (e.g., nitrogen, argon) or reactive atmosphere, you will need a specialized furnace with ports for gas exchange. Assuming a standard furnace is inert is a common and costly mistake.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the right tool, consider your primary objective.

- If your primary focus is quantitative analysis: Use the furnace for ashing to accurately measure the non-combustible content of foods, plastics, or other organic materials.

- If your primary focus is modifying material properties: Leverage the furnace for controlled heat treatments like annealing to improve a metal's ductility or for hardening to increase its strength.

- If your primary focus is material synthesis: Utilize the furnace's clean environment for sintering powders into a solid ceramic part or for creating high-purity glass.

Ultimately, the muffle furnace empowers you to precisely control the transformation of matter, whether for discovery, analysis, or creation.

Summary Table:

| Application | Key Use Cases | Temperature Range |

|---|---|---|

| Analytical Chemistry | Ashing, moisture determination, sample prep | 200°C to 1200°C+ |

| Materials Research | Heat treatment, sintering, brazing | 200°C to 1200°C+ |

| Industrial Processes | Glass fusing, ceramic production | 200°C to 1200°C+ |

Ready to enhance your lab's capabilities with a high-temperature furnace? KINTEK specializes in advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong R&D and in-house manufacturing ensure deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can deliver precise, contaminant-free heating for your applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?