At its core, a modern dental porcelain furnace delivers operational advantages through a combination of digital precision, process automation, and user-centric design. These features work together to provide automatic temperature adjustments for consistency, quiet operation via precision motors, and real-time feedback through status displays, fundamentally improving the quality and efficiency of dental restoration manufacturing.

The true operational advantage is not found in a single feature, but in the furnace's ability to reliably translate a technician's skill into a physically perfect product. It removes process variability, ensuring that every restoration achieves its maximum potential for strength, aesthetics, and fit.

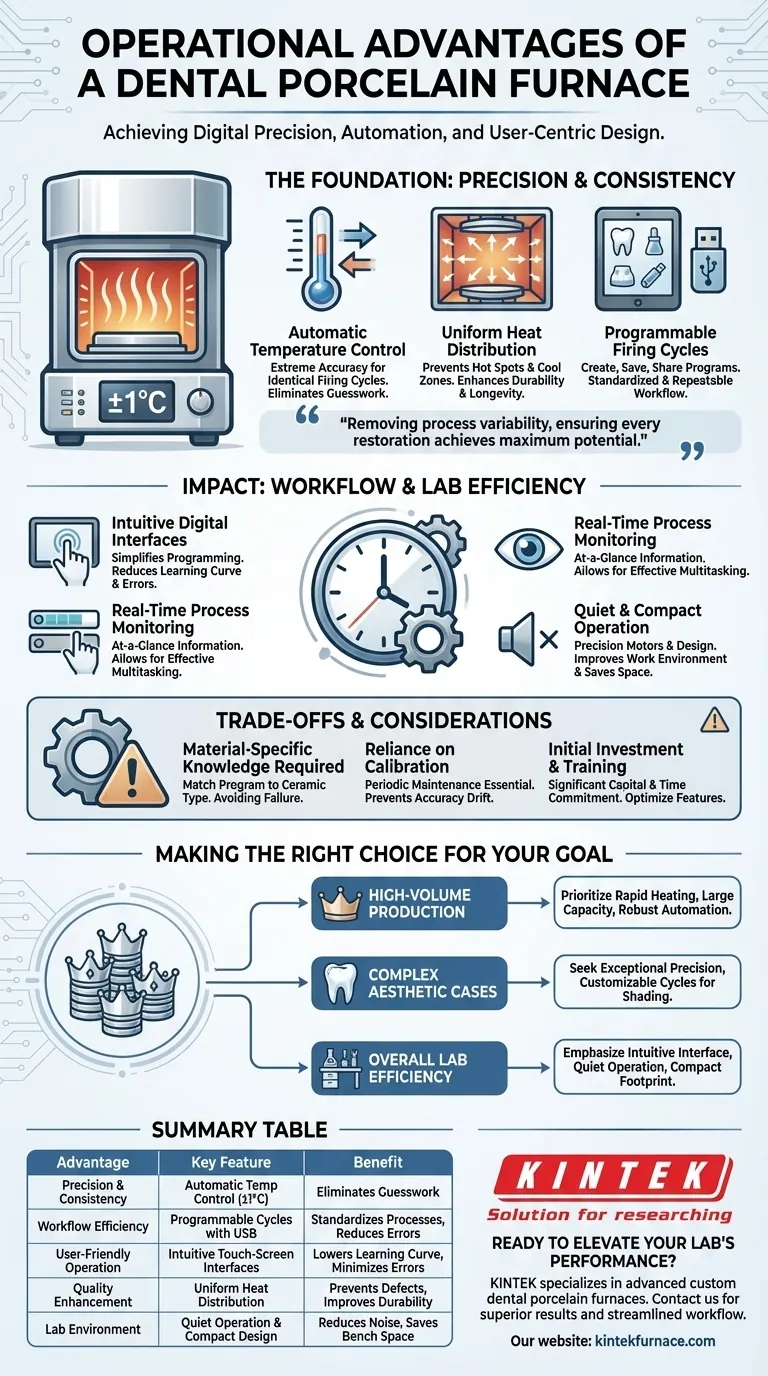

The Foundation: Precision and Consistency

The primary goal of any dental lab is to produce consistent, high-quality results. A modern porcelain furnace is engineered specifically to eliminate the variables that can compromise the final restoration.

Automatic Temperature Control

High-end furnaces maintain temperature with extreme accuracy, often within +/- 1 degree Celsius. This digital precision ensures that every firing cycle is identical, which is critical for achieving the desired material properties, shade, and translucency in the final ceramic.

This removes the guesswork and variability inherent in manual or less precise systems, guaranteeing that the material is sintered or glazed under ideal conditions every time.

Uniform Heat Distribution

The furnace's muffle or chamber is designed to distribute heat evenly across the entire restoration. This prevents hot spots or cool zones that could lead to internal stresses, micro-fractures, or an incomplete sintering process.

Proper heat distribution is directly responsible for the enhanced durability and longevity of crowns, bridges, and veneers.

Programmable Firing Cycles

Technicians can create, save, and recall specific firing programs for different types of ceramics and restorations. With USB connectivity, these programs can be easily shared or backed up.

This programmability ensures that every material is processed according to the manufacturer's exact specifications, creating a standardized and repeatable workflow that is essential for quality control.

The Impact: Workflow and Lab Efficiency

Beyond the quality of the final product, operational advantages have a direct impact on the daily productivity and environment of the dental laboratory.

Intuitive Digital Interfaces

Modern furnaces feature touch-screen interfaces that simplify the complex process of programming firing cycles. This reduces the learning curve for new technicians and minimizes the risk of user error.

Clear on-screen prompts and an organized layout allow for faster setup and less time spent consulting manuals.

Real-Time Process Monitoring

An optical status display provides at-a-glance information on the furnace's current stage, temperature, and remaining time. This allows technicians to multitask effectively, knowing they will be alerted to the cycle's completion or any potential errors.

Quiet and Compact Operation

The use of precision stepper motors for the lift mechanism results in nearly silent operation. This, combined with a compact design, improves the overall work environment by reducing noise and saving valuable bench space in the lab.

Understanding the Trade-offs and Considerations

While highly advantageous, leveraging a modern porcelain furnace requires a clear understanding of its operational demands.

The Need for Material-Specific Knowledge

The furnace's versatility is a significant benefit, but it places responsibility on the technician. You must use the correct program for the specific ceramic material being fired. Applying a generic cycle to a specialized material can result in a complete failure of the restoration.

Reliance on Calibration

To maintain their high precision, these instruments require periodic maintenance and temperature calibration. Neglecting this step can cause the furnace to drift from its specified accuracy, silently undermining the consistency it was designed to provide.

Initial Investment and Training

Advanced furnaces represent a significant capital investment. Realizing their full operational advantage requires an initial time investment for technicians to learn the programming features and understand how to optimize cycles for different aesthetic outcomes.

Making the Right Choice for Your Goal

When evaluating a porcelain furnace, match its features to your laboratory's primary objectives.

- If your primary focus is high-volume production: Prioritize furnaces with rapid heating rates, large program storage capacity, and robust automation to maximize daily throughput.

- If your primary focus is complex aesthetic cases: Seek out exceptional temperature precision (+/- 1°C) and highly customizable firing cycles to achieve fine control over shading and translucency.

- If your primary focus is overall lab efficiency: Emphasize an intuitive user interface, quiet operation, and a compact footprint to improve the daily work environment for your team.

Ultimately, investing in the right porcelain furnace is an investment in predictability, empowering your lab to deliver exceptional quality with unmatched consistency.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| Precision and Consistency | Automatic temperature control (±1°C) | Eliminates guesswork, ensures uniform material properties |

| Workflow Efficiency | Programmable firing cycles with USB | Standardizes processes, reduces errors, saves time |

| User-Friendly Operation | Intuitive touch-screen interfaces | Lowers learning curve, minimizes technician errors |

| Quality Enhancement | Uniform heat distribution | Prevents defects, improves durability and aesthetics |

| Lab Environment | Quiet operation and compact design | Reduces noise, saves bench space |

Ready to elevate your dental lab's performance? KINTEK specializes in advanced high-temperature furnace solutions, including custom dental porcelain furnaces. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique needs—whether for high-volume production, complex aesthetic cases, or overall lab efficiency. Our product line, featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, ensures reliability and precision. Contact us today to discuss how we can help you achieve superior results and streamline your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations