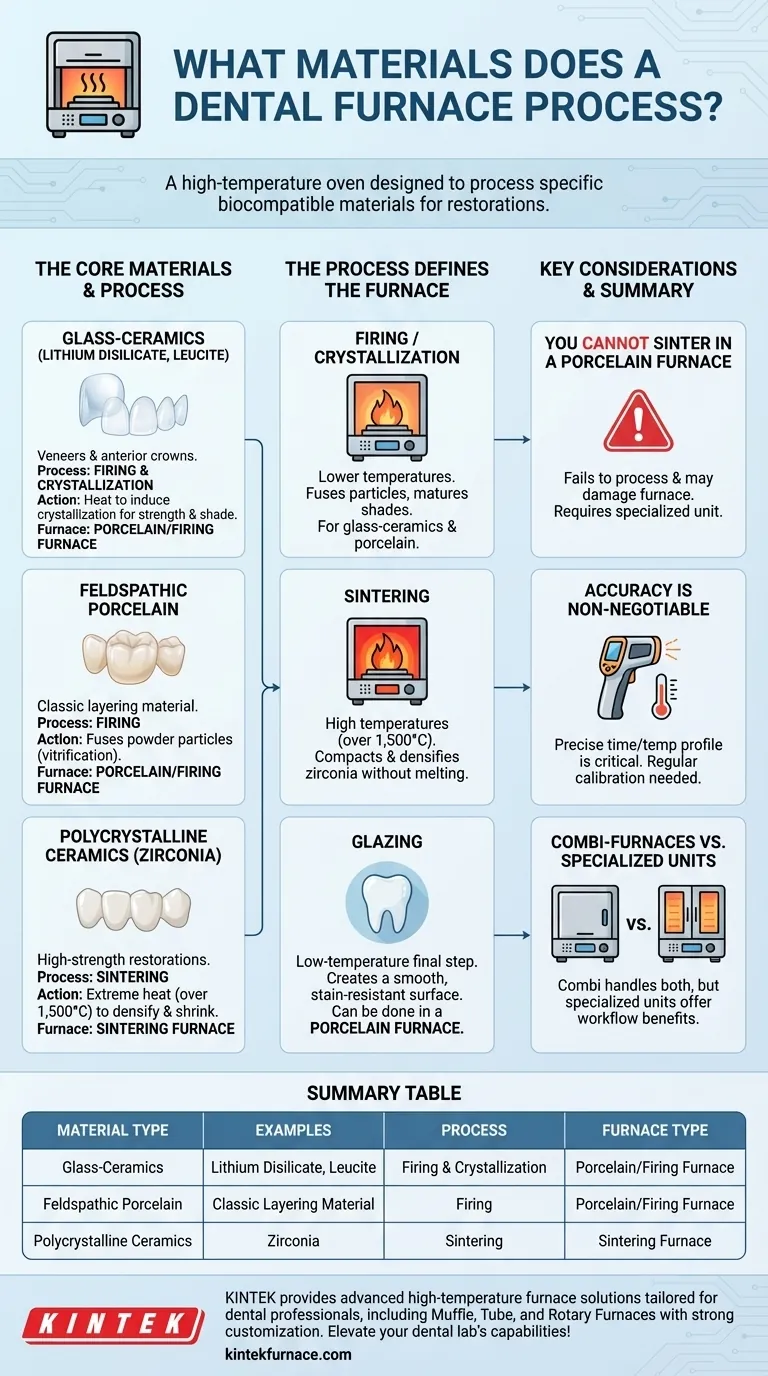

At its core, a dental furnace is a high-temperature oven designed to process specific biocompatible materials into their final, durable state for dental restorations. The primary materials processed are advanced dental ceramics, including various types of porcelain, glass-ceramics like lithium disilicate, and high-strength zirconia.

The specific material a dental furnace processes is less important than the thermal cycle it is designed to execute. Different ceramics require fundamentally different processes—such as firing, sintering, or glazing—each demanding a specific type of furnace to achieve the desired strength, fit, and aesthetics.

The Core Materials: A Focus on Dental Ceramics

A dental furnace is not a one-size-fits-all device. Its capabilities are matched to the chemical and physical properties of the materials it must process. These materials fall into distinct categories.

Glass-Ceramics (Lithium Disilicate & Leucite)

These materials are prized for their excellent translucency and aesthetic qualities, making them ideal for veneers and anterior crowns.

They are processed in what is often called a porcelain or firing furnace. The process involves heating the milled or pressed restoration to a specific temperature to induce crystallization, which gives the material its final strength and shade.

Feldspathic Porcelain

This is the classic material used for layering over a stronger core, such as a metal or zirconia framework. It allows technicians to build up a restoration with incredibly natural-looking color and character.

Like glass-ceramics, feldspathic porcelain is processed in a firing furnace that fuses the powder particles together in a process known as firing or vitrification.

Polycrystalline Ceramics (Zirconia)

Zirconia is the workhorse for high-strength restorations like posterior crowns and multi-unit bridges. It is supplied to the dental lab in a soft, chalky, pre-sintered state that is easy to mill.

This material requires a dedicated sintering furnace. The sintering process heats the zirconia to extremely high temperatures (often over 1,500°C), causing the particles to densify and shrink, transforming the soft block into a solid, exceptionally strong final restoration.

The Process Defines the Furnace

Understanding the distinction between thermal processes is critical. The terms "firing" and "sintering" are not interchangeable; they describe different actions performed by different types of furnaces.

Firing & Crystallization

Firing is a general term for heating ceramic materials to fuse particles and mature shades. This process is used for feldspathic porcelains and for the crystallization of glass-ceramics like lithium disilicate.

These cycles occur at lower temperatures than sintering and are performed in standard porcelain furnaces.

Sintering

Sintering is a specific, high-temperature process used almost exclusively for zirconia. It is a process of solid-state diffusion that compacts the material into a dense, non-porous final form without melting it.

This requires a specialized sintering furnace capable of reaching and precisely holding the extreme temperatures needed to properly densify the zirconia.

Glazing

Glazing is the final step for most ceramic restorations. A thin layer of glass is applied and fired at a relatively low temperature to create a smooth, stain-resistant, and lifelike surface.

Most porcelain firing furnaces have pre-set programs for glazing, and it is a common final step for both fired and sintered restorations.

Understanding the Trade-offs

Choosing and using a dental furnace involves navigating key practical considerations that directly impact a lab's workflow and the quality of the final product.

You Cannot Sinter in a Porcelain Furnace

The most critical distinction is temperature capability. A standard porcelain furnace cannot reach the extreme temperatures required to sinter zirconia. Attempting to do so will fail to process the material and may damage the furnace.

This means a dental lab working with both zirconia and glass-ceramics will almost always require at least two different types of furnaces: a sintering furnace and a firing furnace.

Accuracy is Non-Negotiable

The success of a restoration depends on the furnace's ability to follow a precise time and temperature profile. Any deviation can lead to cracks, poor fit due to incorrect shrinkage, or compromised aesthetics.

This is why proper and regular calibration of the furnace's temperature (pyrometer) is a mission-critical maintenance task in any dental laboratory.

Combi-Furnaces vs. Specialized Units

Some modern "combi" furnaces are designed to handle both the lower-temperature firing of glass-ceramics and the high-temperature sintering of zirconia.

While these offer space and cost savings, high-volume labs often prefer dedicated units. A separate sintering furnace allows for long zirconia cycles to run overnight without tying up the primary firing furnace needed for daily casework.

Making the Right Choice for Your Restoration

Your clinical goal for the restoration dictates the material, which in turn dictates the furnace and process required.

- If your primary focus is anterior aesthetics (veneers, inlays): You will use a firing furnace to process glass-ceramics (lithium disilicate) or to fire layered feldspathic porcelain.

- If your primary focus is high-strength posterior crowns or bridges: You will require a sintering furnace to properly process milled zirconia restorations.

- If your primary focus is the final surface finish of any ceramic: You will use a glazing cycle, which can typically be performed in a standard porcelain firing furnace.

Ultimately, mastering the relationship between material, process, and equipment is fundamental to producing consistent, high-quality dental restorations.

Summary Table:

| Material Type | Examples | Process | Furnace Type |

|---|---|---|---|

| Glass-Ceramics | Lithium Disilicate, Leucite | Firing & Crystallization | Porcelain/Firing Furnace |

| Feldspathic Porcelain | Classic Layering Material | Firing | Porcelain/Firing Furnace |

| Polycrystalline Ceramics | Zirconia | Sintering | Sintering Furnace |

Ready to elevate your dental lab's capabilities? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental professionals. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discover how our furnaces can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures