In short, low vacuum atmosphere furnaces are compatible with a range of materials that are not highly sensitive to oxidation or other atmospheric reactions. This includes common metals like steel and stainless steel, certain alloys, specific ceramics, and glass. These furnaces are ideal for standard heat treatment processes where moderate purity is sufficient and cost-effectiveness is a priority.

The key is understanding that "low vacuum" is not about processing in a void, but about purging ambient air. The work is then done in a backfilled inert "atmosphere," making material suitability dependent on its tolerance for the trace oxygen a low vacuum system leaves behind.

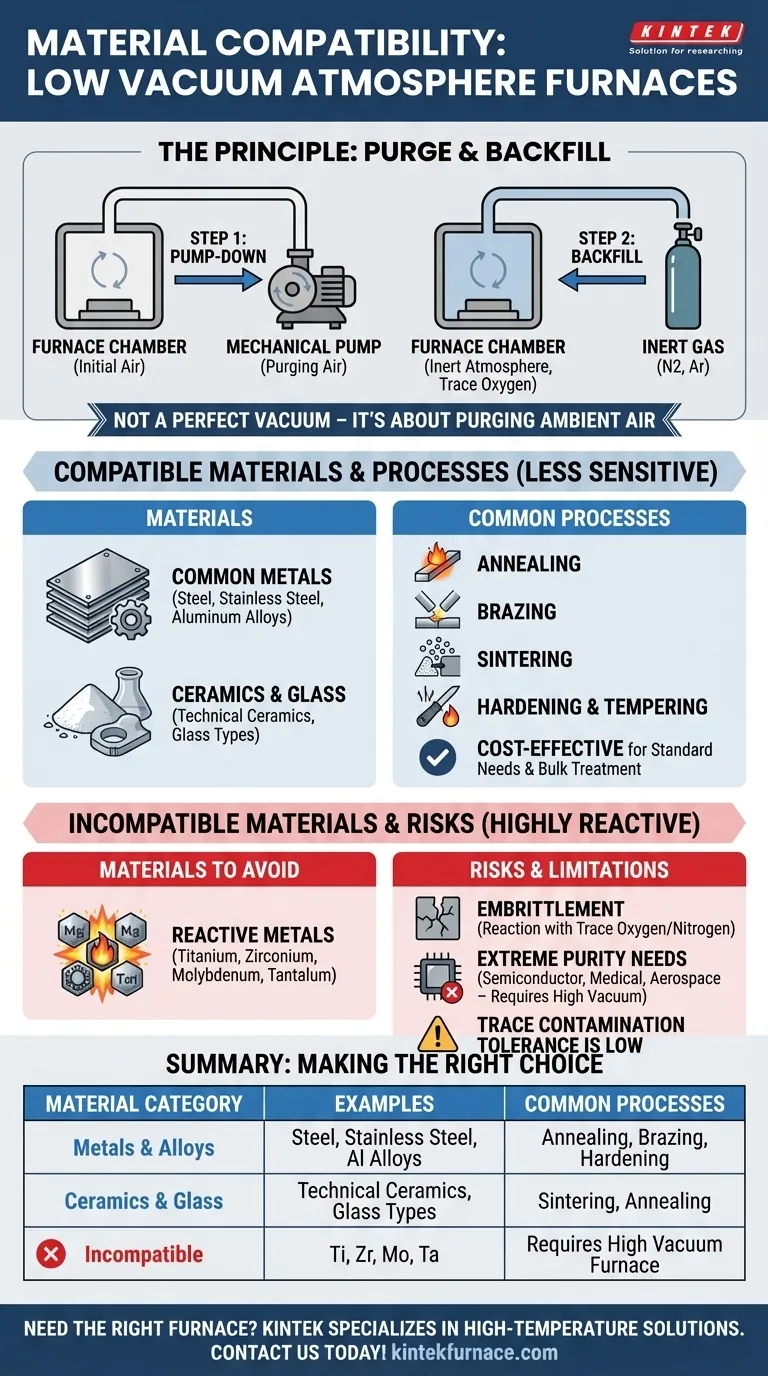

The Principle: It's About Purging, Not a Perfect Vacuum

To understand material compatibility, you first need to understand how these furnaces operate. The name "low vacuum atmosphere furnace" describes a two-step process.

The Role of the "Low Vacuum"

A low vacuum atmosphere furnace does not operate in a deep space-like vacuum. Instead, it uses a mechanical pump (like a rotary vane pump) to remove the majority of the ambient air from the chamber.

This initial step, called a "pump-down," is fundamentally a purging cycle. Its goal is to get rid of most of the reactive oxygen, nitrogen, and moisture present in normal air.

The Importance of the "Inert Atmosphere"

After the initial pump-down, the chamber is backfilled with an inert gas, most commonly nitrogen or argon. This inert atmosphere is the primary protective shield for the material during the high-temperature process.

The "low vacuum" simply ensures that this inert atmosphere is as pure as possible by removing the bulk of the air beforehand.

Compatible Materials and Common Processes

A material is compatible if it can tolerate the residual, trace amounts of oxygen and other gases that this system cannot remove.

Metals and Alloys

These furnaces are workhorses for treating common metals. Materials like steel, stainless steel, and aluminum alloys are frequently processed.

These materials are considered "less sensitive." For example, some steels may form a slight surface oxide that is inconsequential or is removed in a subsequent step. Aluminum brazing is a common application, where the process is designed to work within this environment.

Ceramics and Glass

Many technical ceramics and types of glass are inherently stable and less reactive than metals. They can be processed effectively in low vacuum atmosphere furnaces for applications like sintering or annealing.

Key Industrial Processes

The system's efficiency makes it ideal for high-volume heat treatments where extreme purity isn't the primary goal. Common processes include:

- Annealing: Softening metals to improve ductility.

- Brazing: Joining components, especially aluminum parts in the automotive industry.

- Sintering: Fusing powders together to form a solid mass.

- Hardening & Tempering: Standard heat treatments for tools and parts.

Understanding the Trade-offs: When to Avoid This Furnace

The primary limitation of a low vacuum atmosphere furnace is its inability to achieve high levels of purity. Using the wrong furnace can lead to costly component failure.

Highly Reactive and Refractory Metals

Materials like titanium, zirconium, molybdenum, and tantalum are extremely sensitive to contamination. They readily react with even trace amounts of oxygen, nitrogen, or hydrogen at high temperatures.

This reaction causes embrittlement, catastrophically degrading the material's mechanical properties. These metals demand the purity of a high vacuum furnace.

The Risk of the Inert Gas Itself

For some materials, the "inert" atmosphere isn't truly inert. At elevated temperatures, titanium will react with nitrogen gas to form titanium nitrides, which can also compromise the material. This is a critical consideration often overlooked.

Applications Demanding Extreme Purity

If you are producing components for the semiconductor, medical implant, or aerospace industries, the standards for material purity are absolute. A low vacuum furnace cannot provide the contamination-free environment required for these critical applications.

Making the Right Choice for Your Goal

Selecting the correct furnace technology is a crucial decision based on your material's chemistry and your final product requirements.

- If your primary focus is cost-effective heat treatment of standard steels or bulk materials: A low vacuum atmosphere furnace is an efficient and perfectly suitable choice.

- If your primary focus is joining components like aluminum or copper via brazing: This furnace type is the industry standard and well-suited for the process.

- If your primary focus is processing reactive metals like titanium or refractory metals: You must use a high vacuum furnace to prevent irreversible material damage.

- If your primary focus is achieving absolute chemical purity for medical or electronic parts: Only a high vacuum furnace can meet the stringent contamination control requirements.

Ultimately, selecting the right furnace is a function of knowing your material's reactivity and your process's tolerance for contamination.

Summary Table:

| Material Category | Examples | Common Processes |

|---|---|---|

| Metals & Alloys | Steel, Stainless Steel, Aluminum Alloys | Annealing, Brazing, Hardening |

| Ceramics & Glass | Technical Ceramics, Glass Types | Sintering, Annealing |

| Incompatible Materials | Titanium, Zirconium, Molybdenum, Tantalum | Requires High Vacuum Furnace |

Need the right furnace for your materials? KINTEK specializes in high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our deep customization and in-house manufacturing, we ensure precise fit for your lab's unique needs. Contact us today to enhance your heat treatment efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.