The fundamental maintenance procedures for a muffle furnace focus on four key areas: regular inspection of the heating elements and chamber, periodic calibration of temperature controls, thorough cleaning to prevent contamination, and checks of all electrical and safety systems. Performing these tasks diligently is the most effective way to ensure the furnace operates accurately, safely, and reliably over its lifespan.

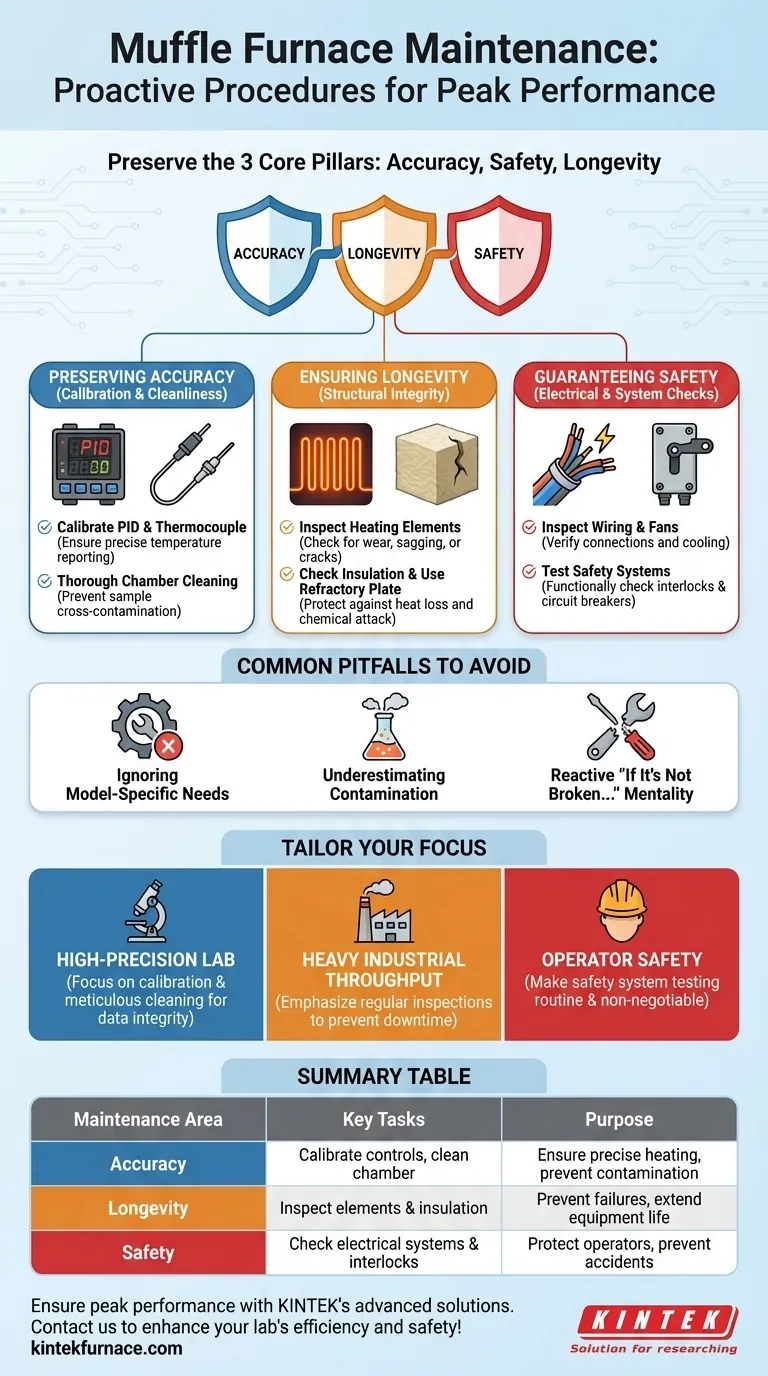

Proactive maintenance is not about fixing what is broken; it is about preserving the three core pillars of your furnace's performance: operational accuracy, operator safety, and equipment longevity. Each recommended task directly supports one or more of these pillars.

The Pillars of Muffle Furnace Maintenance

Understanding the "why" behind each maintenance task transforms it from a chore into a strategic practice. Every procedure is designed to protect the integrity of your processes and the significant investment in the equipment itself.

Preserving Accuracy: Calibration and Cleanliness

Your furnace is a precision instrument. Its value comes from its ability to reliably and repeatedly hit and hold specific temperatures.

A furnace's PID (Proportional-Integral-Derivative) controller is its brain, but the thermocouple is its nervous system. Over time and through thermal cycling, thermocouples can drift, reporting temperatures that are slightly off.

Periodic calibration verifies that the temperature displayed on the controller is the actual temperature inside the chamber. For scientific research or quality control, this accuracy is non-negotiable.

Likewise, residues, oxides, or debris left in the chamber can vaporize at high temperatures and contaminate future samples. This can ruin sensitive processes like technical ceramic firing or metal injection molding. Regular cleaning prevents this cross-contamination.

Ensuring Longevity: Structural and Component Integrity

The furnace chamber and its components are subjected to extreme thermal stress. Regular inspection is critical to catching wear before it leads to catastrophic failure.

Heating elements are the heart of the furnace. Visually inspect them for signs of wear, sagging, or cracking. Replacing a worn element is far less expensive than dealing with a major failure and extended downtime.

The high-purity fibrous alumina insulation is key to the furnace's energy efficiency and temperature stability. Check for cracks or degradation, as compromised insulation leads to heat loss, higher energy bills, and difficulty maintaining a uniform temperature.

For samples that may release corrosive vapors, it is a best practice to place a refractory plate on the chamber floor. This sacrificial layer protects the primary insulation and chamber from chemical attack, significantly extending the furnace's life.

Guaranteeing Safety: Electrical and System Checks

A muffle furnace combines high temperatures with high voltage, a combination that demands respect and regular safety verification.

Visually inspect all wiring and electrical connections for signs of brittleness, discoloration, or fraying. Ensure the cooling fan is operational and its vents are unobstructed to prevent the control cabinet from overheating.

Most importantly, regularly test the safety systems. This includes the circuit breaker and any door safety interlock, which is designed to automatically cut power to the heating elements when the door is opened. Verifying these features function correctly is a critical operator safety measure.

Common Pitfalls to Avoid

Even with a basic checklist, several common oversights can compromise furnace performance and safety.

Ignoring Model-Specific Needs

While the core principles apply to all furnaces, advanced models have additional requirements. Furnaces equipped with vacuum systems, atmosphere controls, or moving parts like elevators require specialized maintenance. Always consult the manufacturer's manual for these specific procedures, such as monitoring vacuum performance or lubricating mechanical components.

Underestimating Contamination Impact

Do not underestimate how quickly a sample can damage a furnace. Materials that release corrosive or volatile substances can degrade heating elements and insulation rapidly. The use of a simple refractory plate is an easy and effective preventative measure.

The "If It's Not Broken..." Mentality

Waiting for a component to fail is the most expensive and dangerous maintenance strategy. Proactive checks and preventative replacements based on inspection will always be more cost-effective and result in less operational downtime than emergency repairs.

Making the Right Choice for Your Goal

Tailor your maintenance frequency and focus to your specific application to maximize efficiency and reliability.

- If your primary focus is high-precision lab results: Prioritize frequent temperature calibration and meticulous chamber cleaning to ensure data integrity and prevent sample cross-contamination.

- If your primary focus is heavy industrial throughput: Emphasize regular visual inspection of heating elements, insulation, and electrical components to prevent unplanned downtime.

- If your primary focus is operator safety (which it always should be): Make the functional testing of safety interlocks and circuit breakers a routine, non-negotiable part of your schedule.

Consistent, thoughtful maintenance is a direct investment in your furnace's long-term performance and safety.

Summary Table:

| Maintenance Area | Key Tasks | Purpose |

|---|---|---|

| Accuracy | Calibrate temperature controls, clean chamber | Ensure precise heating and prevent contamination |

| Longevity | Inspect heating elements and insulation | Prevent failures and extend equipment life |

| Safety | Check electrical systems and safety interlocks | Protect operators and prevent accidents |

Ensure your muffle furnace operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to enhance your lab's efficiency and safety!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation