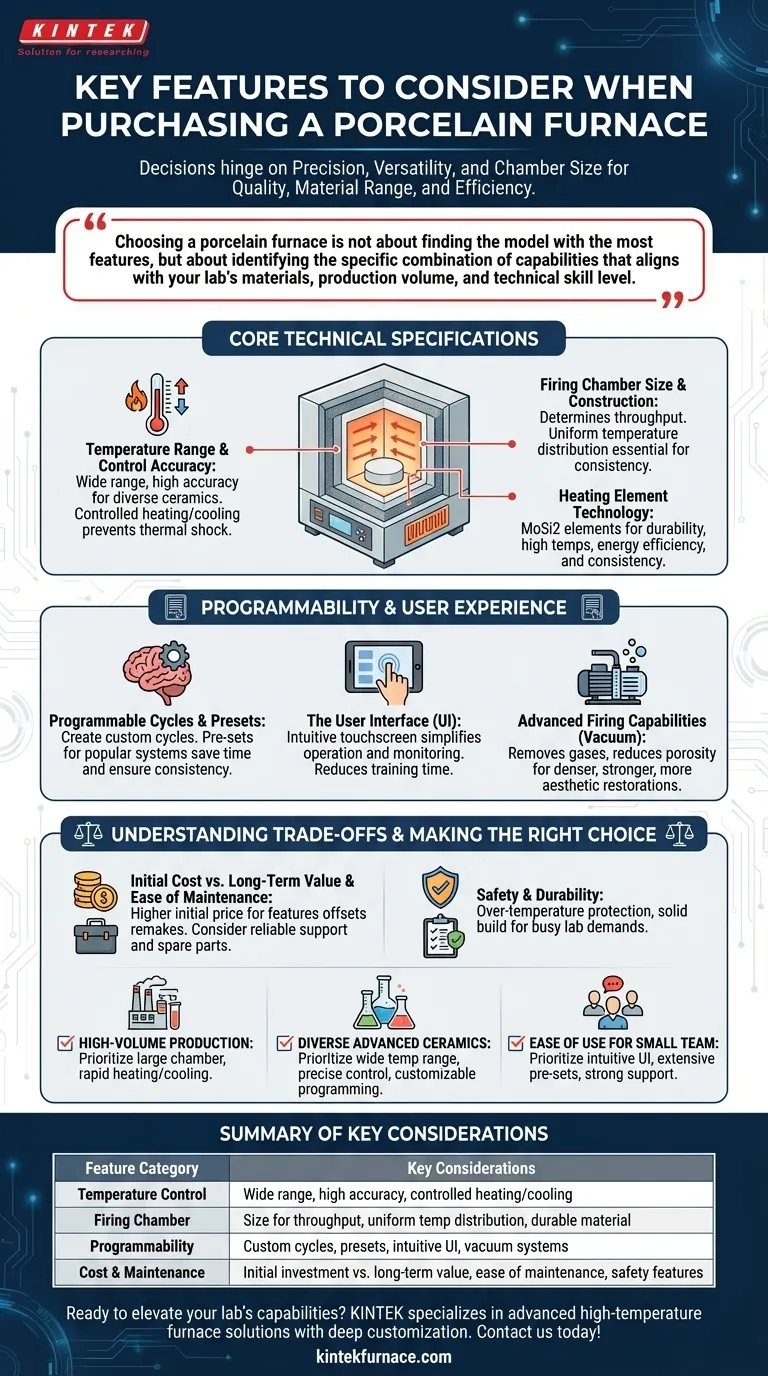

When purchasing a porcelain furnace, the decision hinges on three core pillars: the precision of its temperature control, the versatility of its programming, and the size and construction of its firing chamber. These features directly determine the quality of your restorations, the range of materials you can work with, and the overall efficiency of your lab's workflow.

Choosing a porcelain furnace is not about finding the model with the most features, but about identifying the specific combination of capabilities that aligns with your lab's materials, production volume, and technical skill level. The right furnace is a long-term investment in consistency and quality.

Core Technical Specifications

The foundation of any high-quality porcelain furnace lies in its technical hardware and performance metrics. These specifications are not just numbers on a sheet; they are the direct enablers of predictable, aesthetic results.

Temperature Range and Control Accuracy

A furnace's primary job is to execute a heating cycle with absolute precision. The ability to reach and hold specific temperatures is critical for the vitrification process, which gives porcelain its strength and translucency.

Look for a furnace with a wide temperature range and high temperature control accuracy. This ensures you can work with a variety of ceramics, from low-fusing to high-fusing porcelains, without compromising the material's structural integrity or aesthetic properties.

The heating rate is also a key parameter, as controlled heating and cooling prevent thermal shock and cracking in the final restoration.

Firing Chamber Size and Construction

The size of the firing chamber, or muffle, directly dictates your lab's throughput. A larger chamber allows you to fire more restorations simultaneously, which is essential for high-volume labs.

The chamber's internal material is equally important. It must provide uniform temperature distribution to ensure every restoration in the batch, regardless of its position, is fired under the exact same conditions.

Heating Element Technology

The heating element is the heart of the furnace. Most modern furnaces use molybdenum disilicide (MoSi2) elements, known for their durability and ability to reach high temperatures quickly and cleanly.

The quality and design of these elements impact the furnace's lifespan, energy efficiency, and consistency over thousands of firing cycles.

Programmability and User Experience

A technically sound furnace is only effective if its power is accessible to the technician. The software and user interface are what bridge the gap between the machine's capabilities and the user's intent.

Programmable Cycles and Presets

Modern dental ceramics have highly specific firing parameters. A furnace must offer robust programmability, allowing technicians to create, save, and edit custom firing cycles for different materials and specific cases.

Many furnaces also come with pre-set programs for popular ceramic systems. This feature saves time, reduces the chance of human error, and ensures consistent results, especially in labs with multiple technicians.

The User Interface (UI)

A furnace should feature a clear and intuitive user interface, often a touchscreen display. This simplifies operation, reduces training time, and allows for real-time monitoring of the firing process.

An easy-to-use control panel empowers technicians to make adjustments quickly and confidently, minimizing workflow disruptions and costly errors.

Advanced Firing Capabilities

Some advanced furnaces include vacuum systems. Creating a vacuum during the firing cycle helps to remove gasses and reduce porosity within the porcelain, resulting in a denser, stronger, and more aesthetic final restoration.

Understanding the Trade-offs

Making a smart investment requires an objective look at the compromises between cost, features, and long-term operational needs.

Initial Cost vs. Long-Term Value

More advanced features like highly flexible programmability, a larger firing chamber, and superior build quality will increase the initial price. However, this cost can be offset by greater efficiency, the ability to work with more profitable materials, and a reduction in costly remakes.

View the purchase as an investment in your lab's reputation for quality and its capacity for growth.

Ease of Maintenance and Support

A porcelain furnace is a critical piece of equipment that requires periodic maintenance, such as calibration or replacing a heating element. Consider the ease of maintenance and the availability of reliable manufacturer support and spare parts.

A furnace that is difficult to service can lead to extended downtime, directly impacting your lab's productivity and revenue.

Safety and Durability

Ensure the furnace has essential safety features, such as over-temperature protection, to protect both your staff and your facility. The overall build quality and structural design are indicators of the furnace's expected lifespan and its ability to withstand the demands of a busy lab environment.

Making the Right Choice for Your Lab

Your final decision should be guided by your lab's specific operational goals.

- If your primary focus is high-volume production: Prioritize a furnace with a larger firing chamber and a reputation for rapid, reliable heating and cooling cycles.

- If your primary focus is working with diverse, advanced ceramics: Prioritize a wide temperature range, precise control, and highly customizable programming capabilities.

- If your primary focus is ease of use for a small team: Prioritize a model with an intuitive user interface, extensive pre-set programs, and strong manufacturer support.

By carefully evaluating these features against your unique needs, you can confidently select a furnace that will serve as a reliable foundation for quality and efficiency in your lab for years to come.

Summary Table:

| Feature Category | Key Considerations |

|---|---|

| Temperature Control | Wide range, high accuracy, controlled heating/cooling rates |

| Firing Chamber | Size for throughput, uniform temperature distribution, durable internal material |

| Programmability | Custom cycles, presets, intuitive UI, vacuum systems for advanced firing |

| Cost & Maintenance | Initial investment vs. long-term value, ease of maintenance, safety features |

Ready to elevate your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs, ensuring superior performance and efficiency. Contact us today to discuss how our tailored solutions can benefit your lab!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures