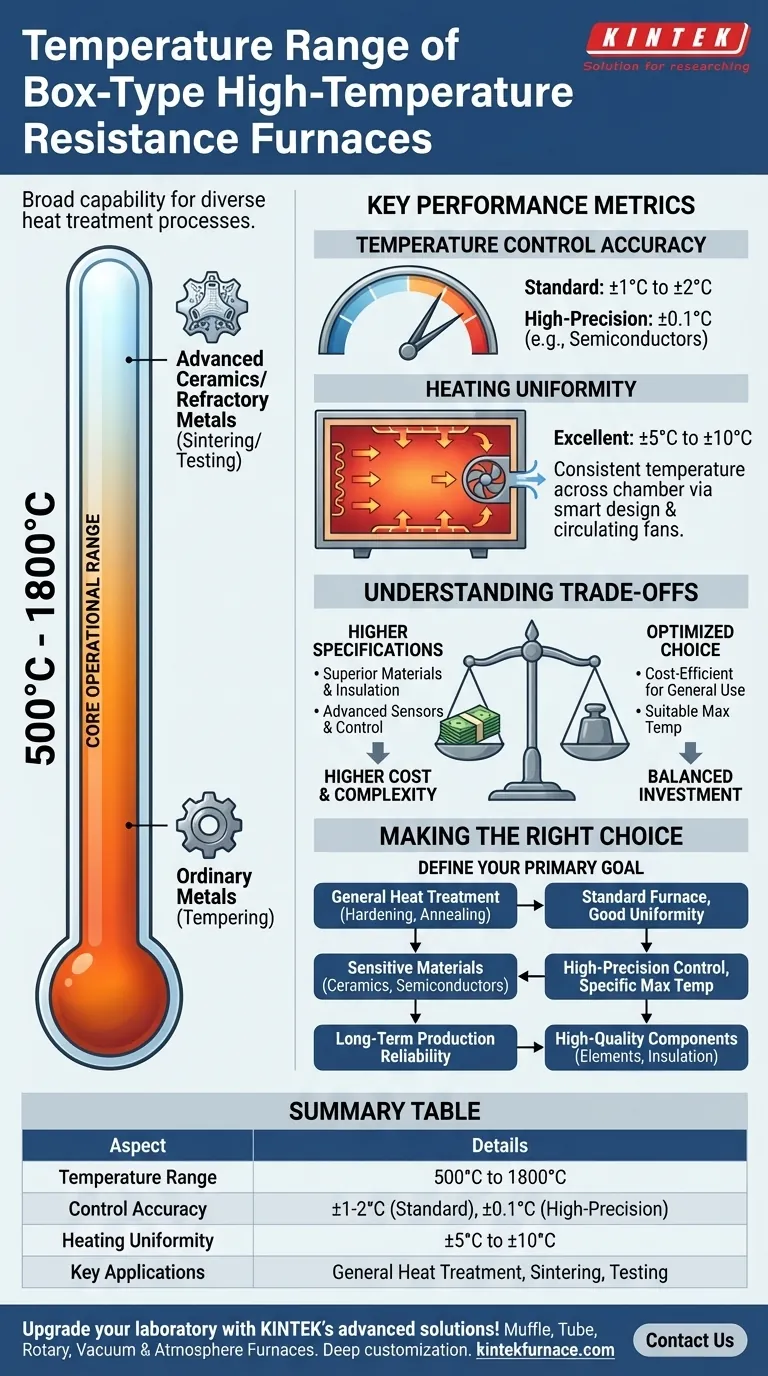

In short, a box-type high-temperature resistance furnace typically operates within a temperature range of 500°C to 1800°C. This broad capability allows them to be used for a wide variety of heat treatment processes on materials ranging from ordinary metals to advanced ceramics and refractory metals.

While the 500°C to 1800°C range defines the furnace's general capability, its true utility for a specific task is determined by three critical factors: the precision of its temperature control, the uniformity of its heat distribution, and the quality of its internal components.

Deconstructing the Temperature Specification

Understanding what goes into the temperature rating is key to selecting the right furnace. The maximum temperature is not just a number; it's a reflection of the furnace's design, materials, and intended purpose.

The Core Operational Range (500°C - 1800°C)

This wide spectrum covers most industrial and laboratory heat treatment needs. Lower temperatures are sufficient for processes like tempering steel, while the upper end is required for sintering advanced ceramics or testing refractory metals.

The Role of Heating Elements and Insulation

A furnace's maximum temperature is dictated by its core components. High-quality heating elements and insulation materials are chosen for their exceptional temperature resistance and oxidation resistance.

This ensures the furnace can not only reach but also sustain high temperatures reliably over a long service life, providing stable operation for continuous use and reducing production downtime.

Beyond Range: Understanding Key Performance Metrics

Simply reaching a high temperature is not enough. For any heat treatment process to be successful and repeatable, two other metrics are arguably more important: accuracy and uniformity.

Temperature Control Accuracy

This metric defines how closely the furnace can maintain a set temperature. It is managed by high-precision temperature control systems and sensors.

Most standard furnaces achieve a control accuracy of ±1°C to ±2°C. However, high-precision models designed for sensitive applications like semiconductor annealing can achieve an accuracy of ±0.1°C.

Heating Uniformity

This refers to the temperature consistency across the entire furnace chamber. Poor uniformity can result in unevenly treated workpieces, leading to defects.

Excellent uniformity, typically within ±5°C to ±10°C, is achieved through intelligent furnace structure design, the strategic arrangement of heating elements, and sometimes the use of circulating fans to ensure even heat distribution.

Understanding the Trade-offs

Choosing a furnace involves balancing capability with cost and complexity. A higher specification in one area often impacts another.

Higher Temperatures Require Superior Materials

A furnace rated for 1800°C uses fundamentally different—and more expensive—heating elements and insulation than a furnace designed for a maximum of 1200°C. Purchasing a furnace with a much higher temperature range than you need results in unnecessary upfront cost.

Precision Comes at a Premium

The advanced sensors and control systems required for high-precision temperature control (±0.1°C) add significant cost. This level of accuracy is critical for certain scientific and manufacturing processes but is overkill for general-purpose heat treatment.

Making the Right Choice for Your Application

To select the correct furnace, you must first define your primary goal.

- If your primary focus is general heat treatment (e.g., hardening, annealing): A standard furnace with good heating uniformity (±5-10°C) and a suitable maximum temperature will be effective and cost-efficient.

- If your primary focus is sensitive materials (e.g., advanced ceramics, semiconductors): Prioritize models with high-precision temperature control (±1°C or better) and the specific maximum temperature your process demands.

- If your primary focus is long-term production reliability: Scrutinize the quality of the heating elements and insulation, as these components directly impact the furnace's service life and operational stability.

Ultimately, selecting the right furnace depends not just on its maximum temperature, but on a clear understanding of your specific process requirements for precision, uniformity, and reliability.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | 500°C to 1800°C |

| Control Accuracy | ±1°C to ±2°C (standard), ±0.1°C (high-precision) |

| Heating Uniformity | ±5°C to ±10°C |

| Key Applications | General heat treatment, sintering ceramics, testing refractory metals |

| Critical Factors | Temperature control, heat distribution, component quality |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications and drive success!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are tubular furnaces important in material testing and research? Unlock Precision for Advanced Materials Development

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More