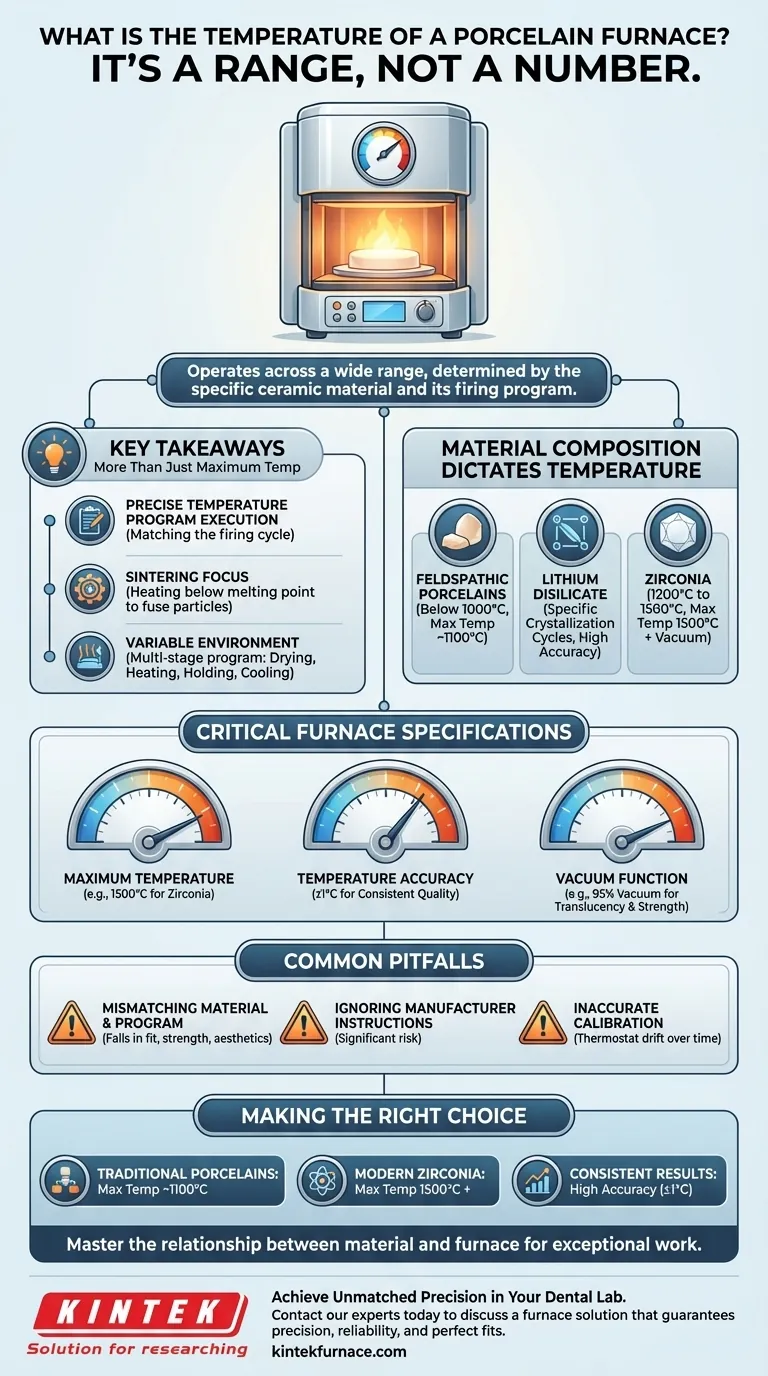

In practice, a dental porcelain furnace operates across a wide temperature range, not at a single fixed point. While many models have a maximum temperature around 1100°C (2012°F), specialized furnaces designed for materials like zirconia can reach up to 1500°C (2732°F). The precise temperature used depends entirely on the specific ceramic material being fired.

The critical takeaway is not the furnace's maximum temperature, but its ability to execute a precise temperature program. Success depends on accurately matching the firing cycle—including heating rates, hold times, and specific temperatures—to the exact requirements of the ceramic manufacturer.

Why Temperature is a Range, Not a Single Number

Understanding a porcelain furnace requires shifting focus from its peak temperature to its function: sintering. This process dictates the need for a variable and highly controlled temperature environment.

The Role of Sintering

Sintering is the process of heating compacted ceramic powder to a temperature high enough to fuse the particles together, creating a solid, dense mass.

This happens below the material's melting point. Different materials have unique sintering temperatures, which is the primary reason there is no single "furnace temperature."

Material Composition is Key

The specific composition of the dental ceramic dictates the required firing temperature.

- Feldspathic porcelains often fire at lower temperatures, sometimes below 1000°C.

- Lithium disilicate glass-ceramics have their own specific crystallization and glazing cycles.

- Zirconia, a high-strength ceramic, requires much higher sintering temperatures, often in the 1200°C to 1500°C range.

The Firing Program

A furnace doesn't just hold one temperature. It follows a multi-stage program with different temperatures and durations for each phase. A typical cycle includes stages for drying, heating, holding at the peak sintering temperature, and controlled cooling.

Understanding Key Furnace Specifications

While the firing program is paramount, certain hardware specifications determine the furnace's capability and the quality of the final restoration.

Maximum Temperature

This indicates the upper limit of what the furnace can achieve. A furnace with a max temperature of 1100°C can handle most traditional porcelains, but one that reaches 1500°C is necessary for sintering certain high-strength zirconia materials.

Temperature Accuracy

This is arguably the most critical specification. A high-quality furnace will have an accuracy of ±1°C.

This precision ensures that the ceramic is not under-fired (resulting in a weak, porous restoration) or over-fired (causing slumping, poor fit, and an unnatural glassy appearance). It guarantees repeatable and predictable results.

Vacuum Function

Many dental porcelain furnaces incorporate a vacuum pump to remove air from the firing chamber. Reaching a deep vacuum (e.g., 95%) prevents air bubbles from being trapped in the porcelain, which improves translucency and strength.

Common Pitfalls and Trade-offs

Achieving a perfect result is dependent on avoiding common errors related to temperature management.

Mismatching Material and Program

The most frequent cause of failure is using a firing program that is not designed for the specific ceramic material in the furnace. This can ruin the restoration's fit, strength, and aesthetics.

Ignoring Manufacturer Instructions

Always defer to the ceramic manufacturer's instructions for use (IFU). They provide scientifically validated firing schedules tested for their specific material composition. Deviating from these recommendations is a significant risk.

Inaccurate Calibration

Over time, a furnace's thermostat can drift. Without periodic calibration, a furnace set to 900°C might actually be heating to 890°C or 910°C, compromising the outcome. Regular maintenance is essential to maintain its stated accuracy.

Making the Right Choice for Your Goal

The correct temperature is not a number, but a carefully followed recipe. Use the material's requirements to guide your furnace programming.

- If your primary focus is firing traditional feldspathic porcelains: Your target temperatures will be on the lower end, and a furnace with a max temperature of 1100°C is generally sufficient.

- If your primary focus is sintering modern zirconia restorations: You must use a high-temperature furnace capable of reaching and holding temperatures between 1200°C and 1500°C.

- If your primary focus is achieving consistent, high-quality results: Prioritize a furnace with excellent temperature accuracy (±1°C) and always follow the specific firing program provided by your ceramic's manufacturer.

Mastering the relationship between your material and the furnace's temperature cycle is the key to producing exceptional ceramic work.

Summary Table:

| Material Type | Typical Sintering Temperature Range | Key Furnace Requirement |

|---|---|---|

| Feldspathic Porcelains | Below 1000°C | Max Temp ~1100°C |

| Lithium Disilicate | Specific Crystallization Cycles | High Accuracy (±1°C) |

| Zirconia | 1200°C to 1500°C | Max Temp 1500°C + Vacuum |

Achieve Unmatched Precision in Your Dental Lab

Struggling with inconsistent ceramic results? The key to perfect dental restorations lies in a furnace with superior temperature accuracy and deep customization.

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including specialized Muffle and Vacuum Furnaces, is designed to handle the precise demands of materials like zirconia and lithium disilicate. With our strong deep customization capability, we can precisely meet your unique sintering requirements, ensuring repeatable, high-quality results every time.

Ready to transform your ceramic workflow? Contact our experts today to discuss a furnace solution that guarantees precision, reliability, and perfect fits for your patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique