At its core, a modern Zirconia Dental Sintering Furnace operates with a temperature accuracy of ±1°C. This level of precision is not just a technical specification; it is the fundamental requirement for producing clinically acceptable dental restorations. Without it, the physical and aesthetic properties of the final zirconia product are compromised.

The question of a furnace's temperature accuracy goes beyond a simple number. It's about understanding that a ±1°C tolerance is the industry standard for ensuring every dental restoration is strong, aesthetically pleasing, and dimensionally correct, thereby eliminating costly remakes and ensuring patient satisfaction.

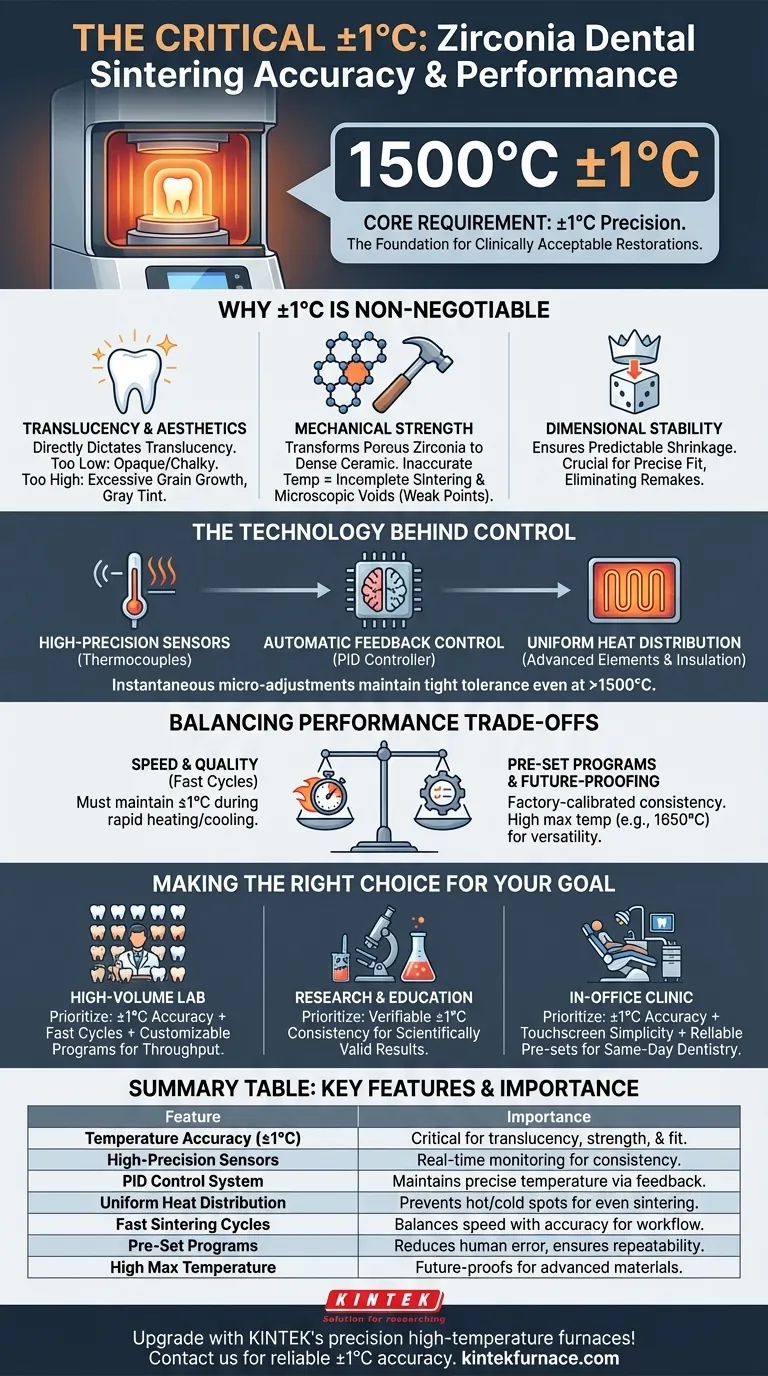

Why ±1°C Accuracy is Non-Negotiable

The success of a zirconia restoration is directly tied to the precision of the sintering cycle. Deviations of even a few degrees can have significant negative consequences on the final product.

The Impact on Translucency and Aesthetics

Sintering temperature directly dictates the final translucency of the zirconia. If the temperature is too low, the material will not fully densify, resulting in an opaque, chalky appearance. If it's too high, the grain size can grow excessively, potentially impacting shade and even causing a grayish tint.

Ensuring Mechanical Strength

The primary function of sintering is to transform the porous, pre-sintered zirconia into a dense, high-strength ceramic. An inaccurate temperature profile can lead to incomplete sintering, leaving microscopic voids that become weak points, dramatically increasing the risk of fracture under oral forces.

Achieving Dimensional Stability

During sintering, the zirconia restoration shrinks significantly. This shrinkage is precisely calculated by the manufacturer and programmed into the CAD/CAM workflow. Achieving the target temperature accurately ensures this shrinkage is predictable, resulting in a crown or bridge that fits the preparation perfectly.

The Technology Behind Precision Control

Maintaining a tight ±1°C tolerance, especially at temperatures exceeding 1500°C, requires a sophisticated system of components working in concert.

High-Precision Temperature Sensors

The process begins with high-quality thermocouples. These sensors constantly measure the internal chamber temperature and relay this information to the furnace's central controller in real-time.

Automatic Feedback Control

The furnace uses an automatic feedback loop, often a PID (Proportional-Integral-Derivative) controller. This system constantly compares the actual temperature from the sensor to the programmed target temperature, making instantaneous micro-adjustments to the power supplied to the heating elements to eliminate fluctuations.

Uniform Heat Distribution

Accuracy at the sensor is useless if the chamber has hot and cold spots. Modern furnaces are engineered with high-purity silicon carbide or molybdenum disilicide heating elements and advanced insulation to ensure uniform thermal distribution, so the entire restoration sinters at the same rate.

Understanding Performance Trade-offs

While accuracy is paramount, other features like speed and programmability also define a furnace's overall performance. Understanding how they interact is key.

The Balance Between Speed and Quality

Some furnaces boast extremely fast cycles, heating at rates of 150°C per minute and completing a cycle in under 30 minutes. This speed enhances lab or clinic workflow but places enormous demands on the control system. The true measure of a quality fast-sintering furnace is its ability to maintain ±1°C accuracy throughout that rapid heating and cooling ramp.

The Value of Pre-Set Programs

The inclusion of built-in, pre-set heating programs is a critical feature for ensuring consistency. These programs are factory-calibrated for specific zirconia brands, removing the risk of human error in programming a complex multi-stage cycle. This translates user-friendliness directly into repeatable, high-quality results.

High Maximum Temperature

A maximum temperature rating, such as 1650°C, provides versatility. While most zirconia sinters around 1450°C to 1550°C, a higher ceiling means the furnace is capable of handling future materials that may require higher temperatures, making it a more future-proof investment.

Making the Right Choice for Your Goal

The ideal furnace depends on your specific operational needs, but the foundation for all of them is uncompromising temperature accuracy.

- If your primary focus is a high-volume dental lab: Prioritize a furnace that combines ±1°C accuracy with fast cycles and a large library of customizable programs to maximize throughput without sacrificing quality.

- If your primary focus is research or education: You need a furnace where the ±1°C accuracy is verifiable and consistent, ensuring that your experimental results are scientifically valid and repeatable.

- If your primary focus is an in-office clinic: Look for the combination of ±1°C accuracy, simple touchscreen operation, and reliable pre-set programs to minimize user error and deliver predictable results for same-day dentistry.

Ultimately, choosing a furnace with proven temperature control is a direct investment in the quality of your work and the efficiency of your practice.

Summary Table:

| Feature | Importance |

|---|---|

| Temperature Accuracy (±1°C) | Critical for translucency, strength, and dimensional stability of zirconia restorations |

| High-Precision Sensors | Ensures real-time temperature monitoring for consistent results |

| PID Control System | Maintains precise temperature through automatic feedback loops |

| Uniform Heat Distribution | Prevents hot/cold spots for even sintering across the restoration |

| Fast Sintering Cycles | Balances speed with accuracy to enhance workflow efficiency |

| Pre-Set Programs | Reduces human error and ensures repeatability for various zirconia brands |

| High Max Temperature (e.g., 1650°C) | Future-proofs the furnace for advanced materials requiring higher heat |

Upgrade your dental lab or clinic with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met, delivering reliable ±1°C accuracy for flawless zirconia restorations. Contact us today to discuss how our furnaces can boost your efficiency and product quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations