In the ceramics industry, the significance of the muffle furnace lies in its ability to provide a precisely controlled, high-temperature environment that is isolated from contaminants. This combination of heat and purity is essential for transforming raw materials into durable, reliable ceramic products through processes like firing and sintering.

The true value of a muffle furnace is not simply the heat it generates, but the control it offers. This precise control over temperature and atmospheric purity is what allows manufacturers and researchers to dictate the final properties of a ceramic material, ensuring consistency, quality, and innovation.

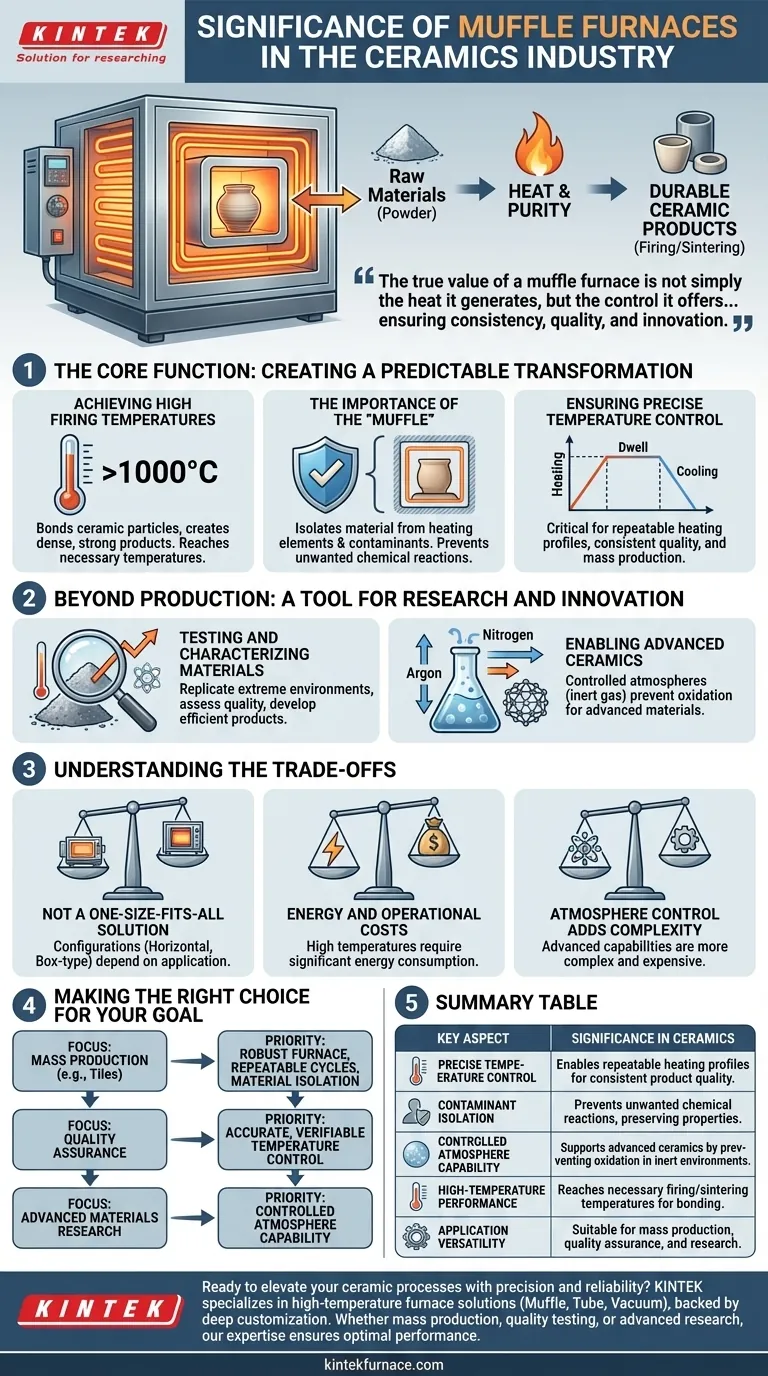

The Core Function: Creating a Predictable Transformation

The creation of any ceramic product, from a simple tile to an advanced electronic component, is fundamentally a process of transformation driven by heat. A muffle furnace provides the ideal environment for this change to occur predictably.

Achieving High Firing Temperatures

Ceramic materials must be heated to very high temperatures in processes known as firing and sintering. This heat causes the individual particles of the ceramic powder to bond and fuse together, creating a dense, strong, and solid final product. Muffle furnaces are engineered to easily and safely reach these necessary temperatures.

The Importance of the "Muffle"

The defining feature of a muffle furnace is its inner chamber, or "muffle." This chamber isolates the ceramic material from the heating elements and any potential contaminants from combustion. This isolation prevents unwanted chemical reactions that could alter the color, strength, or electronic properties of the ceramic.

Ensuring Precise Temperature Control

The final properties of a ceramic are critically dependent on the firing cycle—how fast it's heated, how long it's held at peak temperature, and how it cools. Muffle furnaces offer highly precise temperature control, allowing for the creation of repeatable heating profiles. This is vital for consistent quality in mass production.

Beyond Production: A Tool for Research and Innovation

While essential for manufacturing, the role of muffle furnaces extends into the research and development that pushes the industry forward.

Testing and Characterizing Materials

Researchers use muffle furnaces to replicate extreme environments and test the behavior of new ceramic formulations. By observing how materials respond to specific heat treatments, they can assess quality, predict durability, and develop more efficient products.

Enabling Advanced Ceramics

Modern muffle furnaces can operate with controlled atmospheres, such as in low-oxygen or inert gas environments (e.g., argon or nitrogen). This capability is indispensable for developing advanced materials, like certain technical ceramics or nanomaterials, that would otherwise oxidize and be ruined if heated in open air.

Understanding the Trade-offs

While indispensable, choosing and using a muffle furnace involves practical considerations. Its capabilities must be matched to the specific goal.

Not a One-Size-Fits-All Solution

Furnaces come in various configurations, such as horizontal or box-type models. The choice depends entirely on the application, from small-scale lab experiments to large industrial annealing and sintering processes.

Energy and Operational Costs

Achieving and maintaining temperatures often exceeding 1000°C requires a significant amount of energy. For industrial-scale operations, energy consumption is a major factor in cost and efficiency calculations.

Atmosphere Control Adds Complexity

Furnaces with atmosphere control offer advanced capabilities but are more complex and expensive to operate. The decision to use one is a trade-off between the need to process sensitive materials and the added operational overhead.

Making the Right Choice for Your Goal

The "significance" of a muffle furnace is directly tied to your objective. Use these guidelines to frame its importance for your specific application.

- If your primary focus is mass production (e.g., tiles, refractory materials): Your priority is a robust furnace that provides repeatable temperature cycles and reliable material isolation to ensure product consistency.

- If your primary focus is quality assurance: You require a furnace with exceptionally accurate, verifiable temperature control to test if materials meet performance specifications.

- If your primary focus is advanced materials research: The ability to control the furnace atmosphere is as critical as temperature, enabling the development of next-generation ceramics.

Ultimately, mastering the controlled environment of the muffle furnace is fundamental to mastering the art and science of ceramics.

Summary Table:

| Key Aspect | Significance in Ceramics |

|---|---|

| Precise Temperature Control | Enables repeatable heating profiles for consistent product quality and material properties. |

| Contaminant Isolation | Prevents unwanted chemical reactions, preserving color, strength, and electronic characteristics. |

| Controlled Atmosphere Capability | Supports advanced ceramics by preventing oxidation in inert gas environments. |

| High-Temperature Performance | Reaches necessary firing and sintering temperatures for bonding ceramic particles. |

| Application Versatility | Suitable for mass production, quality assurance, and research across various ceramic types. |

Ready to elevate your ceramic processes with precision and reliability? KINTEK specializes in high-temperature furnace solutions, including Muffle, Tube, and Vacuum Furnaces, backed by deep customization to meet your unique needs. Whether you're in mass production, quality testing, or advanced research, our expertise ensures optimal performance and innovation. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?