In solar cell production, Chemical Vapor Deposition (CVD) is a cornerstone manufacturing process used to create the essential thin-film layers that convert sunlight into electricity. It is not just one technique but a family of processes used to both build the core photovoltaic material and to add functional coatings that significantly boost the cell's overall efficiency and durability.

The core challenge in solar cell manufacturing is creating a perfectly structured, multi-layered semiconductor device at an industrial scale. CVD is significant because it provides the atomic-level precision required to deposit these ultra-thin films, directly determining the final performance and economic viability of the solar cell.

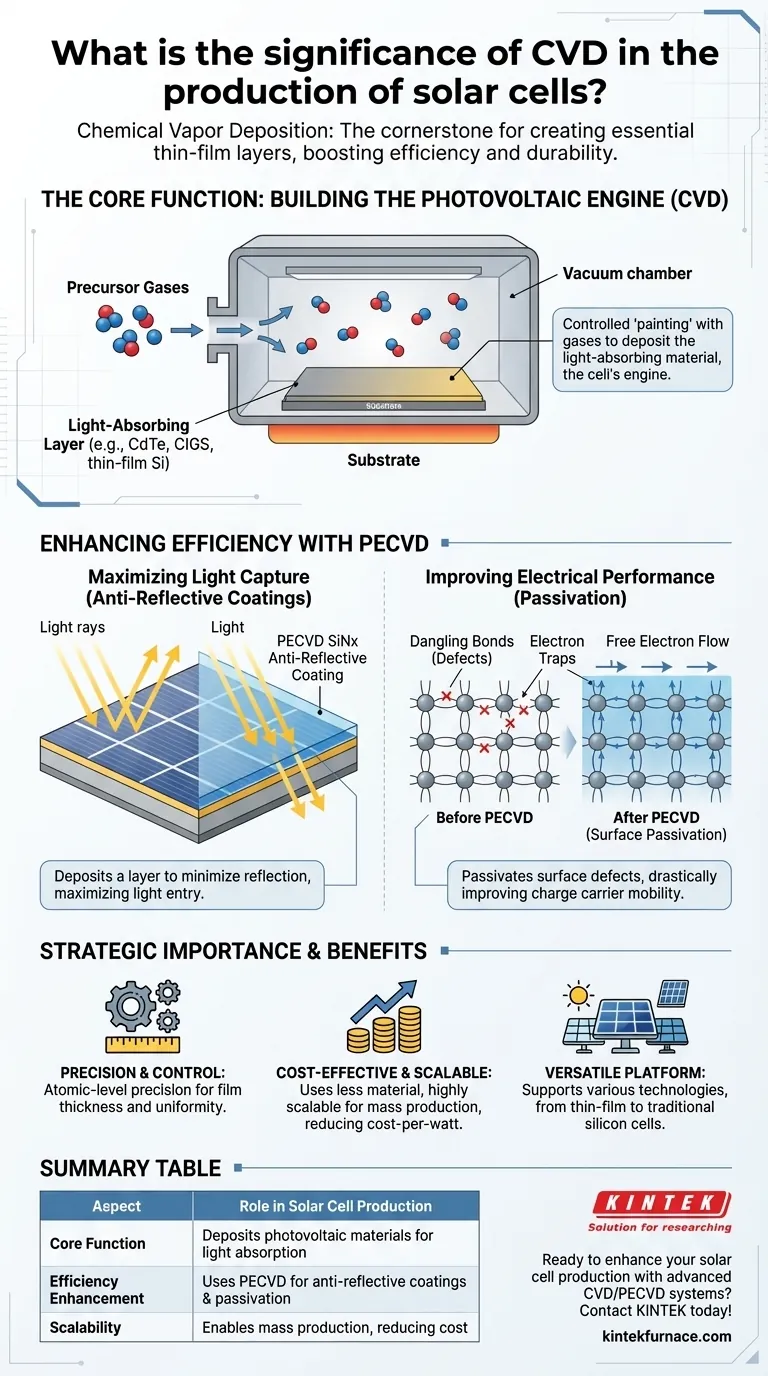

The Core Function: Building the Photovoltaic Engine

At its heart, a solar cell is a specialized semiconductor designed to capture photons and release electrons. CVD is the technology used to construct the most critical parts of this device.

What is Chemical Vapor Deposition?

Think of CVD as a highly controlled "painting" process using chemical gases. Precursor gases are introduced into a vacuum chamber containing the base material, or substrate. These gases react and decompose on the hot substrate surface, forming a solid, ultra-thin film with a highly ordered structure.

Depositing the Light-Absorbing Layer

The primary role of CVD is to deposit the photovoltaic material—the very layer that absorbs sunlight. This is the engine of the solar cell.

For thin-film solar cells, CVD is used to create layers of materials like cadmium telluride (CdTe), copper indium gallium selenide (CIGS), or various forms of thin-film silicon. The precise control CVD offers over the film's thickness and chemical composition is essential for optimizing the cell's light absorption and electrical properties.

Beyond the Engine: Enhancing Efficiency with PECVD

While standard CVD builds the core, a specialized, lower-temperature variant called Plasma-Enhanced CVD (PECVD) is critical for adding layers that enhance performance without damaging the underlying cell structure.

The Role of Plasma-Enhanced CVD (PECVD)

PECVD uses plasma to energize the precursor gases, allowing the deposition process to occur at much lower temperatures. This is vital when adding layers on top of already-fabricated parts of the solar cell that are sensitive to heat.

Maximizing Light Capture with Anti-Reflective Coatings

A significant portion of sunlight can reflect off the shiny surface of a solar cell, wasting potential energy. PECVD is used to deposit a transparent silicon nitride (SiNx) film that acts as an anti-reflective coating.

This layer is engineered to a specific thickness that minimizes reflection and maximizes the amount of light that enters the cell, directly increasing its power output.

Improving Electrical Performance Through Passivation

This is one of the most critical and subtle roles of PECVD. During manufacturing, microscopic defects, or "dangling bonds," can form on the surface of the silicon. These defects act as traps for the electrons freed by sunlight, reducing the cell's efficiency.

The hydrogen-rich silicon nitride film deposited by PECVD "passivates" these defects, effectively healing the surface. This surface passivation allows electrons to move more freely, drastically improving charge carrier mobility and the overall performance of the solar cell.

Understanding the Trade-offs and Strategic Importance

Like any advanced manufacturing process, CVD involves a balance of benefits and challenges that are crucial to understand.

Precision vs. Process Complexity

The greatest strength of CVD is its ability to control film thickness and uniformity with atomic-level precision. However, this requires sophisticated and expensive furnace systems that manage high vacuum, precise temperatures, and the controlled flow of reactive gases.

Cost-Effectiveness and Scalability

Thin-film solar cells, which rely heavily on CVD, use significantly less raw material than traditional thick silicon wafers. This, combined with the fact that CVD processes are highly scalable for mass production, is a key driver in reducing the overall cost-per-watt of solar energy.

A Versatile and Indispensable Tool

CVD's significance comes from its versatility. It is not limited to one type of solar technology. It is used to enhance traditional silicon wafer cells with passivation layers and is the foundational process for multiple generations of thin-film technologies, making it a vital platform for both current production and future innovation.

How to Apply This to Your Project

Your focus will determine which aspect of CVD technology is most relevant to your goals.

- If your primary focus is maximizing cell efficiency: The application of PECVD for depositing high-quality anti-reflective and passivation layers is your most critical area of interest.

- If your primary focus is developing next-generation, low-cost solar: Your attention should be on how CVD enables the deposition of novel thin-film materials like CdTe, CIGS, or perovskites.

- If your primary focus is industrial-scale manufacturing: The scalability, uniformity control, and throughput of large-area CVD systems are the most important factors for achieving economic viability.

Ultimately, CVD is the technology that transforms raw chemical gases into the high-performance heart of a modern solar cell, making it an indispensable enabler of clean energy.

Summary Table:

| Aspect | Role in Solar Cell Production |

|---|---|

| Core Function | Deposits photovoltaic materials (e.g., CdTe, CIGS) for light absorption |

| Efficiency Enhancement | Uses PECVD for anti-reflective coatings and surface passivation |

| Scalability | Enables mass production, reducing cost-per-watt |

| Versatility | Supports various solar technologies, including thin-film and silicon cells |

Ready to enhance your solar cell production with advanced high-temperature furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge CVD/PECVD systems, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we meet your unique experimental needs for precise thin-film deposition, boosting efficiency and scalability. Contact us today to discuss how our solutions can drive your clean energy innovations forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition