There is no fixed service life for a Molybdenum Disilicide (MoSi2) heating element. While they are known for exceptionally long operational lifespans, their longevity is not measured in a set number of hours but is instead a direct result of their operating environment, temperature, and maintenance practices. Under ideal conditions, they can last for many years, but specific factors can cause them to fail much sooner.

The lifespan of a MoSi2 element is not a built-in feature; it is a dynamic outcome of its environment. The key to maximizing its life lies in understanding and preserving the fragile, self-healing silica layer that protects it from degradation.

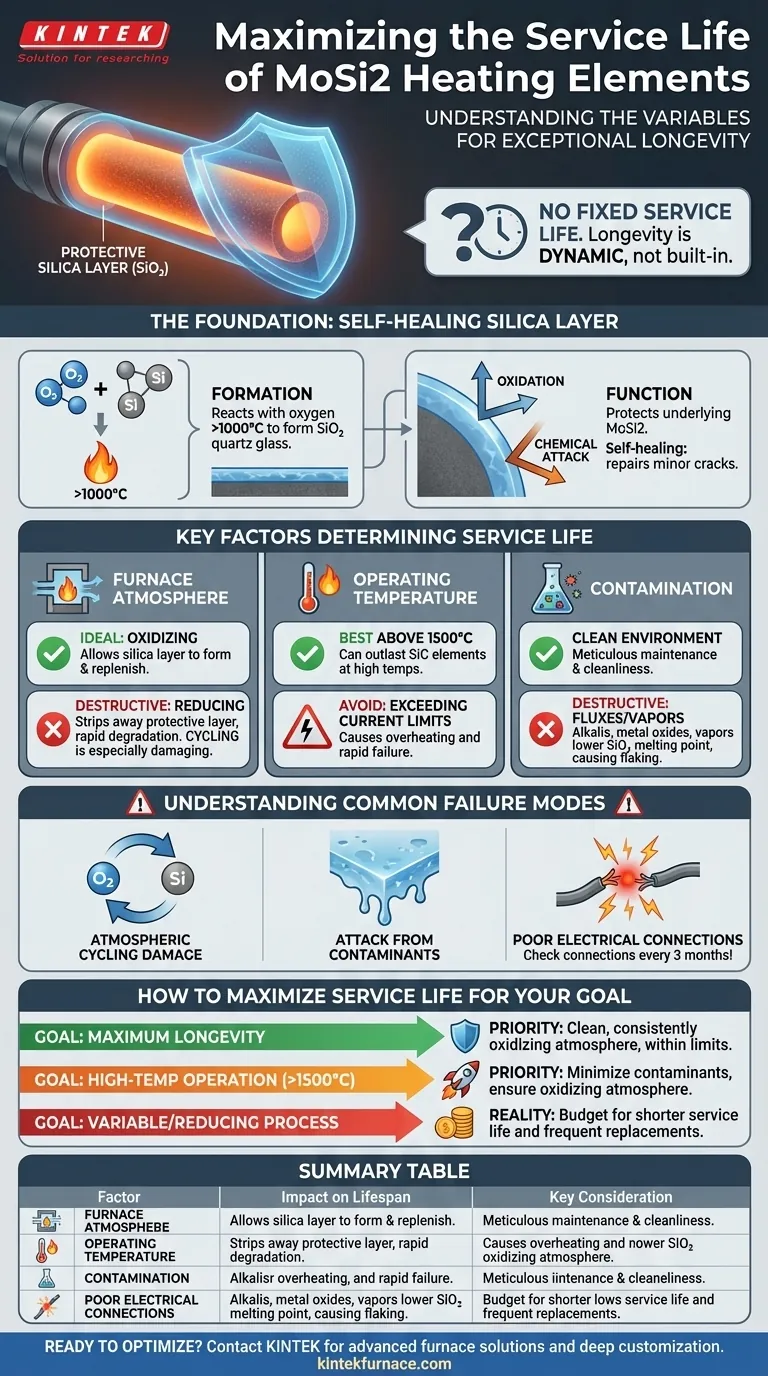

The Foundation of MoSi2 Longevity: The Protective Silica Layer

To understand what determines the service life of a MoSi2 element, we must first understand how it protects itself at high temperatures.

How the Protective Layer Forms

When a MoSi2 element is heated above 1000°C in an oxidizing atmosphere (like air), a chemical reaction occurs on its surface. The silicon within the element reacts with oxygen to form a thin, non-porous layer of quartz glass (silica, SiO2).

Why This Layer is Critical

This silica layer is the key to the element's survival. It acts as a protective barrier, preventing the underlying Molybdenum Disilicide from further oxidation and chemical attack. This layer is "self-healing," meaning minor cracks or flaws that develop during operation can be repaired as new silica forms.

Key Factors That Determine Service Life

The stability of the protective silica layer is directly influenced by several operational factors. Controlling these variables is the most important thing you can do to extend element life.

Furnace Atmosphere

The chemical environment inside the furnace is the single most critical factor. MoSi2 elements thrive in oxidizing atmospheres that allow the silica layer to form and replenish itself.

Conversely, reducing atmospheres are highly destructive. They chemically strip away the protective silica layer, exposing the core material to rapid degradation and significantly shortening the element's life. Repeatedly cycling between oxidizing and reducing environments is especially damaging.

Operating Temperature

MoSi2 elements are designed for very high-temperature applications. In fact, they can last longer than Silicon Carbide (SiC) elements when operated consistently above 1500°C.

However, their high-temperature capability also makes them sensitive to electrical load. Each element has a maximum current limit that must not be exceeded, as this can cause overheating and rapid failure.

Contamination

The silica layer is vulnerable to chemical attack from various contaminants. Foreign materials introduced into the furnace can react with the silica, causing it to flake off or become porous.

A common example is with zirconia processing. If colored or painted zirconia is not properly dried before sintering, the released vapors can attack the elements. Meticulous furnace maintenance and cleanliness are essential.

Understanding Common Failure Modes

Proactive management of your furnace environment is crucial for avoiding premature element failure. Be aware of these common pitfalls.

Damage from Atmospheric Cycling

The most common failure mode is damage from an unstable atmosphere. If your process involves switching between oxidizing and reducing conditions, you will continuously build and then strip away the protective layer, leading to rapid consumption of the element.

Attack from Contaminants

Any substance that can act as a "flux" for silica glass poses a threat. This includes alkalis, certain metal oxides, and other vapors. These materials lower the melting point of the silica layer, causing it to become less viscous and drip off, exposing fresh MoSi2 to be attacked.

Poor Electrical Connections

MoSi2 elements are typically wired in series. A loose connection at any point in the circuit creates high resistance, leading to localized overheating and a potential burnout at the connection point. The references recommend checking all connections every three months to ensure they remain tight.

How to Maximize Service Life for Your Goal

- If your primary focus is maximum longevity in a stable process: Prioritize a clean, consistently oxidizing atmosphere and operate within the element's specified temperature and current limits.

- If your primary focus is high-temperature operation (>1500°C): MoSi2 is an excellent choice, but you must ensure contaminants are minimized and the atmosphere remains oxidizing to leverage its full lifespan potential.

- If your process involves variable or reducing atmospheres: Recognize that MoSi2 elements are not ideal for this scenario, and you should budget for a significantly shorter service life and more frequent replacements.

By diligently controlling these key operating factors, you can transform the potential for long service life into a reliable reality.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Furnace Atmosphere | Critical | Oxidizing extends life; reducing shortens it |

| Operating Temperature | High sensitivity | Best above 1500°C; avoid exceeding current limits |

| Contamination | Destructive | Keep furnace clean to protect silica layer |

| Electrical Connections | Risk of failure | Check every 3 months for tightness |

Ready to optimize your high-temperature processes with durable MoSi2 heating elements? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, helping you achieve maximum element lifespan and efficiency. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability