In Plasma-Enhanced Chemical Vapor Deposition (PECVD), temperature is a primary control parameter that directly governs the final quality and structural integrity of the deposited thin film. It dictates the behavior of reactive particles on the substrate surface, influencing film density, uniformity, hydrogen content, and adhesion. While plasma creates the reactive species, temperature provides the necessary thermal energy to organize them into a high-quality material.

The central role of temperature in PECVD is to strike a critical balance. It must be high enough to produce a dense, uniform film with desirable properties, yet low enough to avoid damaging the underlying substrate, which is the core advantage of the PECVD technique.

The Fundamental Role of Thermal Energy

In any chemical vapor deposition process, energy is required to form a stable film. PECVD uses plasma to provide most of this energy, but thermal energy (heat) still plays a crucial, complementary role.

Governing Surface Mobility

Once precursor molecules are broken down by the plasma, the resulting atoms and fragments (adsorbed species) land on the substrate surface. Temperature provides them with the thermal energy to move around.

Higher temperatures enhance this surface mobility, allowing particles to migrate across the surface and settle into the most energetically favorable sites. This leads to a denser, more ordered film with better uniformity and fewer structural defects.

Influencing Chemical Reactions

While plasma creates the highly reactive species, temperature can influence which surface chemical reactions are completed. It helps drive off volatile byproducts, such as hydrogen, from the growing film.

This process is critical for achieving a pure film with low hydrogen content, which directly correlates to higher film quality and slower etch rates in subsequent processing steps.

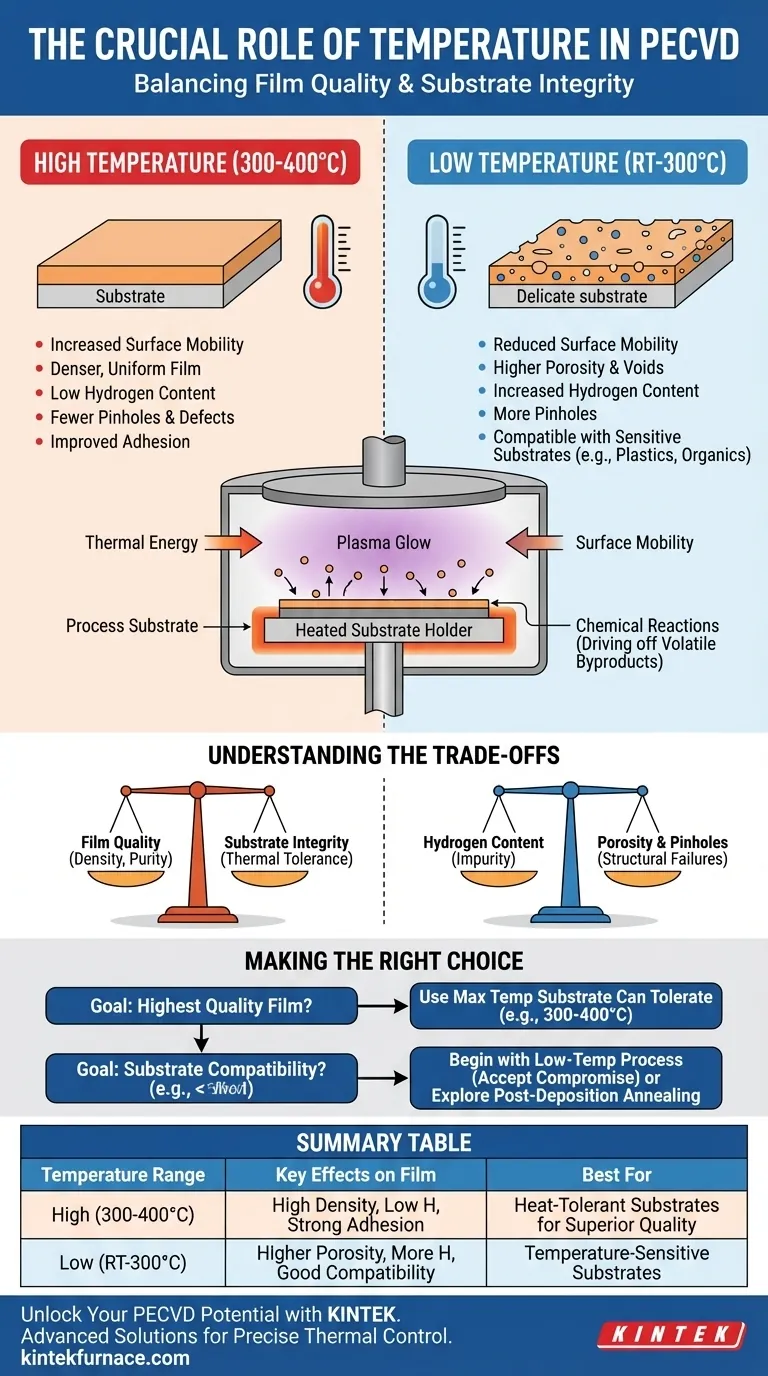

High Temperature vs. Low Temperature Deposition

The choice of deposition temperature is a defining trade-off in any PECVD process. The typical operating range for PECVD is between room temperature and approximately 400°C.

The Benefits of Higher Temperatures

Operating near the upper end of the PECVD temperature range (e.g., 350-400°C) generally produces the highest quality films.

These films exhibit lower hydrogen content, greater density, and improved adhesion. The increased surface mobility at these temperatures minimizes the formation of microscopic voids and pinholes, resulting in a more robust and stable material.

The Necessity of Lower Temperatures

The primary advantage of PECVD over traditional Chemical Vapor Deposition (CVD) is its ability to operate at significantly lower temperatures.

This is essential for applications involving temperature-sensitive substrates. Materials like plastics for flexible electronics or devices with existing organic layers would be degraded or destroyed by the high temperatures of conventional CVD. PECVD allows for deposition on these materials without compromising their integrity.

Understanding the Trade-offs

Selecting a temperature is not about finding a single "best" value, but about understanding the compromises required for a specific application.

Film Quality vs. Substrate Integrity

This is the core dilemma. You must use a temperature that the substrate can tolerate. Pushing for the highest quality film with a high temperature is pointless if it destroys the device you are trying to build.

Conversely, using a very low temperature to protect a delicate substrate often results in a film that is more porous, contains more hydrogen, and may have poorer electronic or mechanical properties.

The Hydrogen Content Dilemma

In many silicon-based films (like silicon nitride or silicon dioxide), incorporated hydrogen is considered an impurity that can degrade performance.

Higher temperatures are very effective at driving hydrogen out of the film as it grows. Low-temperature processes inherently trap more hydrogen, which can be a significant drawback for certain electronic applications.

Porosity and Pinholes

Lower temperatures result in lower surface mobility for the depositing particles. They tend to "stick where they land" rather than finding an optimal position in the film's structure.

This immobility leads to the formation of microscopic voids, creating a less dense, more porous film. These pores can manifest as pinholes, which are critical failure points in dielectric or barrier layers.

Making the Right Choice for Your Goal

Your optimal temperature setting is determined entirely by your substrate limitations and your performance requirements for the final film.

- If your primary focus is the highest possible film quality: Use the maximum temperature your substrate and underlying device layers can safely tolerate, typically in the 300-400°C range.

- If your primary focus is compatibility with sensitive substrates: Begin with a low-temperature process and accept the inherent compromise in film quality, or investigate post-deposition annealing to improve the film properties.

Ultimately, temperature is the most powerful tool you have to fine-tune the properties of your film within the unique constraints of your project.

Summary Table:

| Temperature Range | Key Effects on Film | Best For |

|---|---|---|

| High (300-400°C) | High density, low hydrogen, strong adhesion | Substrates that tolerate heat for superior quality |

| Low (Room to 300°C) | Higher porosity, more hydrogen, good compatibility | Temperature-sensitive substrates like plastics |

Unlock the Full Potential of Your PECVD Processes with KINTEK

Struggling to balance film quality and substrate integrity in your PECVD applications? KINTEK specializes in advanced high-temperature furnace solutions, including our CVD/PECVD Systems, designed to deliver precise thermal control for optimal thin-film deposition. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether you're working with sensitive materials in flexible electronics or demanding high-performance films.

Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and outcomes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab