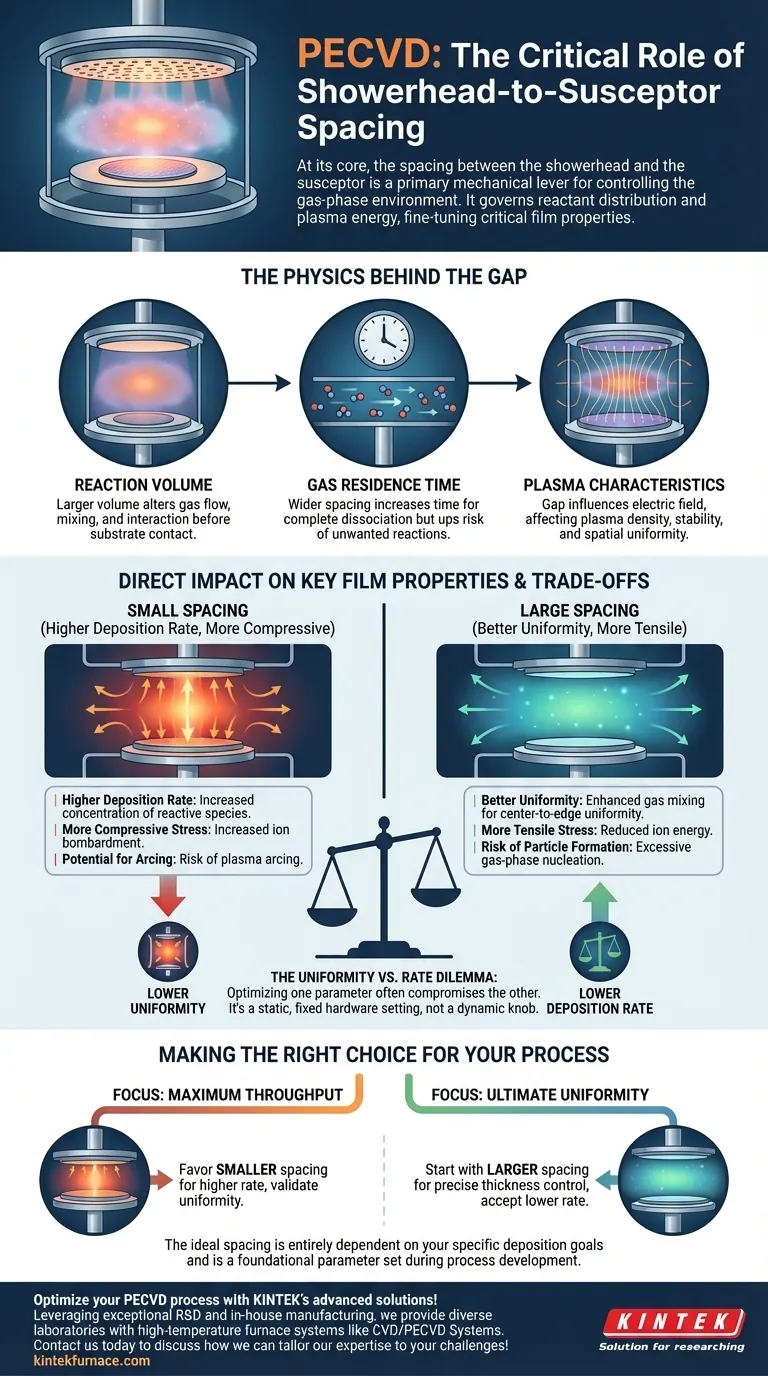

At its core, the spacing between the showerhead and the susceptor is a primary mechanical lever for controlling the gas-phase environment in a Plasma-Enhanced Chemical Vapor Deposition (PECVD) system. This gap directly governs the distribution of reactant gases and plasma energy, which in turn allows engineers to fine-tune critical film properties like within-wafer uniformity, deposition rate, and intrinsic film stress.

Adjusting the showerhead-to-susceptor spacing is not merely a geometric change; it fundamentally alters the reaction volume, gas residence time, and plasma characteristics. Mastering this parameter is about finding the optimal balance between deposition rate and film quality for a specific process.

The Physics Behind the Gap

In a PECVD chamber, the space between the gas-delivering showerhead and the substrate-holding susceptor is not empty. It is the active reaction volume where plasma is generated and precursors are broken down into reactive species that ultimately form the thin film.

Defining the Reaction Volume

The distance dictates the volume in which the critical gas-phase reactions occur. A larger volume (wider gap) changes the way gases flow, mix, and interact with the plasma before reaching the substrate surface.

Governing Gas Residence Time

A wider spacing increases the average time a precursor molecule spends within the plasma before reaching the wafer or being pumped out. This longer residence time can lead to more complete dissociation but also increases the risk of unwanted gas-phase reactions and particle formation.

Modulating Plasma Characteristics

The gap distance influences the electric field between the two parallel plates (showerhead and susceptor). This affects the plasma's density, stability, and spatial uniformity, which directly impacts the uniformity of the ion and radical flux bombarding the wafer surface.

Direct Impact on Key Film Properties

Changing the spacing provides a powerful, albeit coarse, method for adjusting the final film characteristics. The effects are interconnected and stem from the physical changes described above.

Achieving Within-Wafer Uniformity

This is often the primary reason for adjusting the spacing. A larger gap can allow reactant gases to mix more thoroughly before reaching the wafer, which can improve center-to-edge uniformity. The depleted reactants at the wafer's center have more opportunity to be replenished by fresh gas diffusing from the sides.

Controlling Deposition Rate

The deposition rate is highly sensitive to spacing. A smaller gap increases the concentration and flux of reactive species arriving at the substrate, leading to a higher deposition rate. Conversely, a larger gap reduces this flux as species have a greater chance to recombine or be pumped away, thus lowering the deposition rate.

Adjusting Film Stress

Film stress is influenced by factors like ion bombardment energy and film density. A larger gap can alter the plasma sheath, potentially reducing the energy of ions hitting the wafer, which may shift the stress in a more tensile direction. A smaller, more intense gap can increase bombardment, often making the film more compressive.

Understanding the Trade-offs

Adjusting the showerhead spacing is a game of compromise. Optimizing one parameter often comes at the expense of another.

The Uniformity vs. Rate Dilemma

The most fundamental trade-off is between uniformity and deposition rate. Engineers often increase the spacing to achieve better film uniformity, but must accept the consequence of a slower process, which reduces wafer throughput.

Process Stability and Particle Formation

A very small gap can be unstable, increasing the risk of plasma arcing between the showerhead and substrate. A very large gap can lead to excessive gas-phase nucleation, where particles form in the plasma volume and then fall onto the wafer, creating defects.

A Static, Not Dynamic, Parameter

It is critical to understand that on most commercial PECVD tools, the showerhead spacing is not an easily adjustable "knob" for every run. It is a hardware setting that is typically fixed during the installation or optimization of a specific film process. Adjusting it often requires breaking vacuum and significant technician effort.

Making the Right Choice for Your Process

The ideal spacing is entirely dependent on the specific goals of your deposition process. It is a foundational parameter set during process development to establish the baseline performance of the tool.

- If your primary focus is maximum throughput: You will likely favor a smaller spacing to achieve a higher deposition rate, but must carefully validate that film uniformity and defectivity remain within specification.

- If your primary focus is ultimate film uniformity: You will start with a larger spacing, accepting the lower rate as a necessary trade-off for achieving precise thickness control across the entire wafer.

- If you are developing a new process: Treat the spacing as a key variable to explore during initial characterization to find a stable process window that balances rate, uniformity, and stress.

Understanding how this single geometric parameter influences the complex physics inside the chamber is fundamental to mastering your PECVD process.

Summary Table:

| Property | Small Spacing Effect | Large Spacing Effect |

|---|---|---|

| Deposition Rate | Higher | Lower |

| Film Uniformity | May decrease | Improves |

| Film Stress | More compressive | More tensile |

| Process Stability | Risk of arcing | Risk of particle formation |

Optimize your PECVD process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing film quality and throughput. Contact us today to discuss how we can tailor our expertise to your challenges!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth