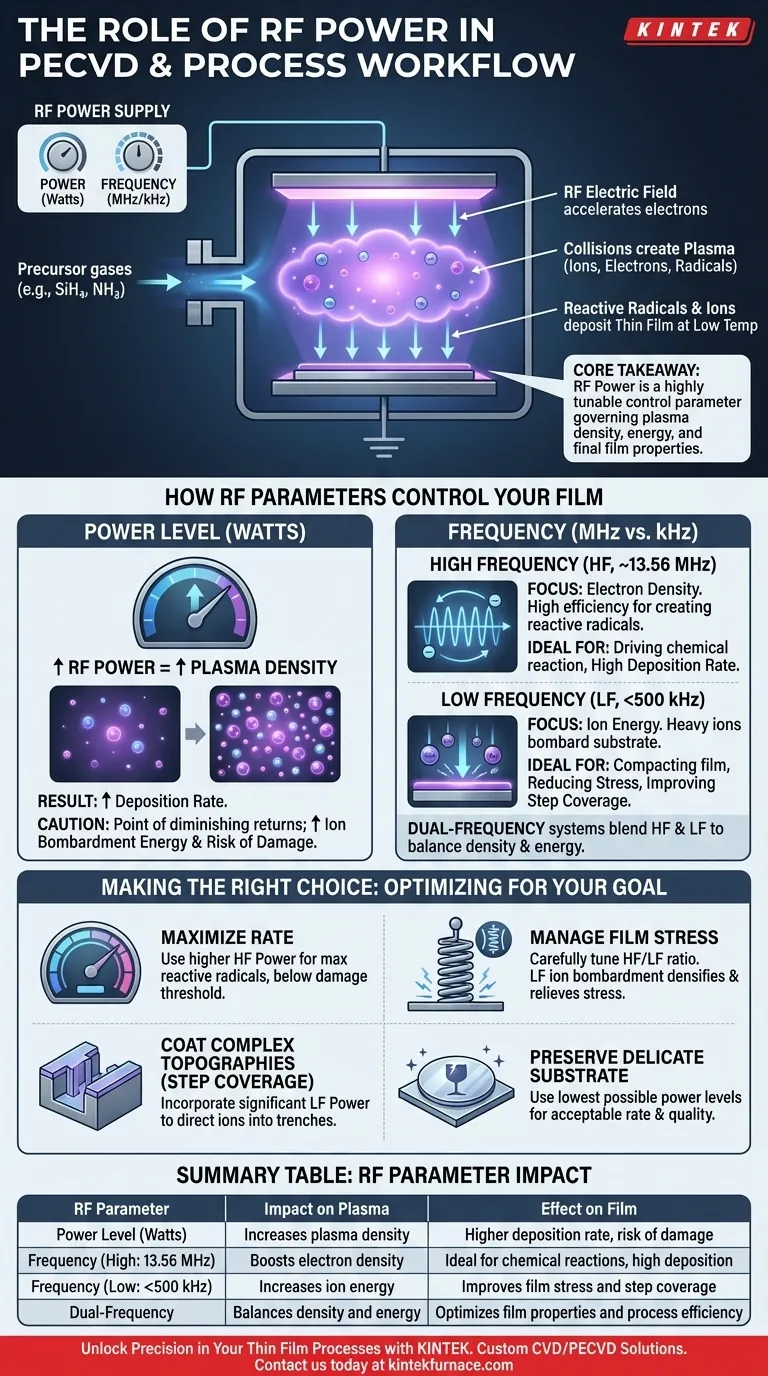

In any Plasma-Enhanced Chemical Vapor Deposition (PECVD) system, RF (Radio Frequency) power is the essential energy source that ignites and sustains a plasma. This plasma transforms relatively inert precursor gases into highly reactive chemical species, enabling the growth of thin films on a substrate at significantly lower temperatures than are possible with purely thermal methods.

The core takeaway is that RF power is not merely an "on" switch for the reaction. It is a highly tunable control parameter. The specific power level (in Watts) and frequency (in MHz or kHz) you apply directly determine the plasma's density and energy, which in turn govern the final film's deposition rate, physical structure, and internal stress.

The Fundamental Role of RF Power: From Gas to Plasma

PECVD operates within a vacuum chamber where reactant gases are introduced. The RF power supply is the heart of this process, responsible for creating the conditions necessary for film deposition.

Creating the Electric Field

The process begins by applying an RF voltage between two electrodes within the chamber. One electrode is typically grounded, often serving as the substrate holder, while the other is energized by the RF power supply. This creates a rapidly oscillating electric field in the space between them.

The Cascade of Ionization

This oscillating electric field grabs free electrons present in the low-pressure gas and accelerates them. These high-energy electrons collide with neutral gas molecules (like silane, SiH₄, or ammonia, NH₃).

These collisions are energetic enough to knock additional electrons off the gas molecules, creating a cascade effect. The result is a partially ionized gas, or plasma, composed of positive ions, negative electrons, and highly reactive neutral fragments called free radicals.

Why Plasma is the Key

Traditional Chemical Vapor Deposition (CVD) relies on high temperatures (often >600°C) to break down precursor gases. The reactive free radicals and ions within a plasma, however, are the actual chemical building blocks for the thin film.

Because RF power creates these reactive species directly, the substrate itself does not need to be heated to extreme temperatures. This allows for deposition on temperature-sensitive materials like polymers or pre-processed semiconductor wafers.

How RF Parameters Control Your Film

Simply creating a plasma is not enough; controlling its properties is critical for engineering a specific film. The two main RF knobs you can turn are power and frequency, and each has a distinct effect.

The Impact of Power Level (Watts)

Increasing the RF power level generally increases the density of the plasma. More power leads to more energetic electrons, more frequent collisions, and thus a higher concentration of free radicals.

This directly increases the film deposition rate. However, there is a point of diminishing returns. Once the precursor gas is substantially ionized, further increases in power may not increase the rate and can instead lead to higher ion bombardment energy.

The Critical Role of Frequency (MHz vs. kHz)

The frequency of the RF power has a profound and distinct impact on the plasma's behavior.

High Frequency (HF), typically 13.56 MHz, primarily influences the electron density. At this high frequency, the heavy ions in the plasma cannot respond to the rapidly changing electric field. Only the light electrons oscillate, making HF very efficient at generating a dense cloud of reactive free radicals. This is ideal for driving the chemical reaction.

Low Frequency (LF), typically <500 kHz, primarily influences ion energy. At these lower frequencies, the heavier positive ions have enough time to accelerate in response to the electric field. This causes them to bombard the substrate surface with significant energy, which can compact the growing film, reduce stress, and improve step coverage in complex trench-like structures.

Understanding the Trade-offs

Manipulating RF parameters is a balancing act. Optimizing for one property often comes at the expense of another.

High Power: The Risk of Damage

While higher power boosts the deposition rate, it also increases the energy of ion bombardment. Excessive bombardment can introduce defects, create unwanted stress, or even physically sputter and damage the growing film or the underlying substrate.

Low Power: The Challenge of Deposition Rate

Operating at very low power is gentler on the substrate but results in a slow deposition rate. This can make the process too time-consuming and costly for high-volume manufacturing environments.

Frequency Duality: The Need for Balance

Using only HF power may produce a high deposition rate but can result in films with poor mechanical properties or high internal stress. Conversely, using only LF power may be inefficient at creating the plasma in the first place. This is why many advanced PECVD systems are dual-frequency, blending HF and LF power to independently control plasma density and ion bombardment energy.

Making the Right Choice for Your Process

Your optimal RF settings depend entirely on the desired outcome for your thin film.

- If your primary focus is maximizing deposition rate: Use a higher HF power level to generate the highest possible density of reactive radicals, but stay below the point where film damage occurs.

- If your primary focus is managing film stress: Carefully tune the ratio of HF to LF power. A small amount of LF ion bombardment can help densify the film and relieve tensile or compressive stress.

- If your primary focus is coating complex topographies (step coverage): Incorporate a significant LF power component to drive ions directionally into trenches and onto sidewalls.

- If your primary focus is preserving a delicate substrate: Use the lowest possible power levels that still achieve an acceptable deposition rate and film quality.

Mastering these RF parameters transforms PECVD from a complex process into a precise and powerful engineering tool for thin film fabrication.

Summary Table:

| RF Parameter | Impact on Plasma | Effect on Film |

|---|---|---|

| Power Level (Watts) | Increases plasma density | Higher deposition rate, risk of damage |

| Frequency (High: 13.56 MHz) | Boosts electron density | Ideal for chemical reactions, high deposition |

| Frequency (Low: <500 kHz) | Increases ion energy | Improves film stress and step coverage |

| Dual-Frequency | Balances density and energy | Optimizes film properties and process efficiency |

Unlock Precision in Your Thin Film Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you need to optimize deposition rates, manage film stress, or coat complex topographies.

Contact us today to discuss how our tailored PECVD solutions can enhance your research and production efficiency!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- What are gas barrier films, and how is PECVD involved in their creation? Discover Advanced Packaging Solutions

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films