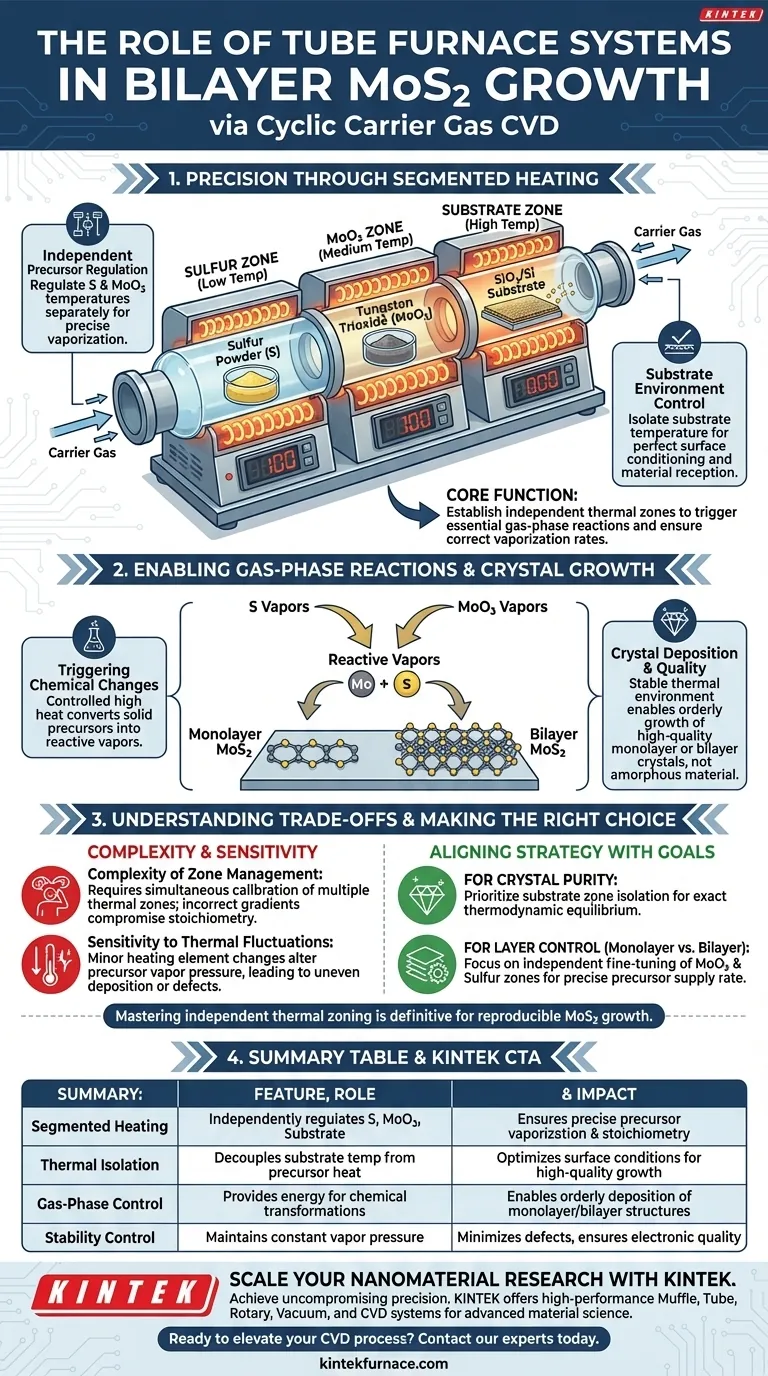

The tube furnace system acts as the precise thermal engine for the synthesis process. It provides the strictly controlled high-temperature environment required to grow molybdenum disulfide (MoS2). Its primary role is to utilize segmented temperature control to independently regulate the thermal conditions of the tungsten trioxide (MoO3) precursor, sulfur powder (S), and the target substrate.

The core function of the tube furnace is to establish independent thermal zones that trigger essential gas-phase chemical reactions. This segmentation ensures that precursors vaporize at the correct rates to deposit high-quality monolayer or bilayer crystals onto SiO2/Si substrates.

Precision Through Segmented Heating

Independent Precursor Regulation

The success of growing bilayer MoS2 relies on handling different materials simultaneously. The tube furnace utilizes segmented temperature control to manage this complexity.

It allows you to regulate the temperature of the tungsten trioxide (MoO3) precursor separately from the sulfur powder (S). This is critical because these materials have vastly different vaporization points and reactivity profiles.

Substrate Environment Control

Beyond the precursors, the furnace maintains a distinct thermal zone for the substrate itself.

By isolating the substrate temperature, the system ensures the SiO2/Si surface is conditioned perfectly to receive the depositing material. This independence prevents the substrate conditions from being dictated solely by the heat required to vaporize the precursors.

Enabling Gas-Phase Reactions

Triggering Chemical Changes

The furnace does not simply heat materials; it facilitates a chemical transformation. The controlled high temperatures trigger specific chemical reactions in the gas phase.

This thermal environment converts the solid precursors into reactive vapors. Without this precise energy input, the precursors would remain inert or react unpredictably.

Crystal Deposition and Quality

The ultimate role of the furnace is to facilitate the orderly deposition of material.

By maintaining a stable thermal environment, the system enables the growth of high-quality crystals. This control is what allows for the specific formation of monolayer or bilayer structures rather than amorphous or bulk material.

Understanding the Trade-offs

Complexity of Zone Management

While segmented temperature control offers precision, it introduces significant complexity to the setup.

You must calibrate multiple thermal zones simultaneously. If the temperature gradient between the sulfur zone and the MoO3 zone is not optimized, the stoichiometry of the final MoS2 crystal will be compromised.

Sensitivity to Thermal Fluctuations

The reliance on gas-phase reactions makes the process highly sensitive to thermal instability.

Even minor fluctuations in the furnace's heating elements can alter the vapor pressure of the precursors. This can lead to uneven deposition or defects in the bilayer structure, reducing the electronic quality of the material.

Making the Right Choice for Your Goal

To achieve the best results with a tube furnace CVD system, you must align your thermal strategy with your specific material objectives.

- If your primary focus is crystal purity: Prioritize the precise isolation of the substrate zone to ensure the SiO2/Si surface is at the exact thermodynamic equilibrium for clean deposition.

- If your primary focus is layer control (Monolayer vs. Bilayer): Focus on the independent fine-tuning of the MoO3 and Sulfur zones to strictly control the rate of precursor supply to the reaction.

Mastering the independent thermal zoning of your furnace is the definitive step toward reproducible MoS2 growth.

Summary Table:

| Feature | Role in MoS2 Synthesis | Impact on Final Material |

|---|---|---|

| Segmented Heating | Independently regulates S, MoO3, and Substrate zones | Ensures precise precursor vaporization and stoichiometry |

| Thermal Isolation | Decouples substrate temperature from precursor heat | Optimizes surface conditions for high-quality crystal growth |

| Gas-Phase Control | Provides energy for chemical transformations | Enables orderly deposition of monolayer or bilayer structures |

| Stability Control | Maintains constant vapor pressure of reactants | Minimizes defects and ensures electronic quality consistency |

Scale Your Nanomaterial Research with KINTEK

Achieve uncompromising precision in your MoS2 synthesis. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for advanced material science. Whether you need standard lab furnaces or fully customizable high-temperature solutions, our systems provide the segmented thermal control essential for monolayer and bilayer crystal growth.

Ready to elevate your CVD process? Contact our technical experts today to find the perfect furnace for your unique research needs.

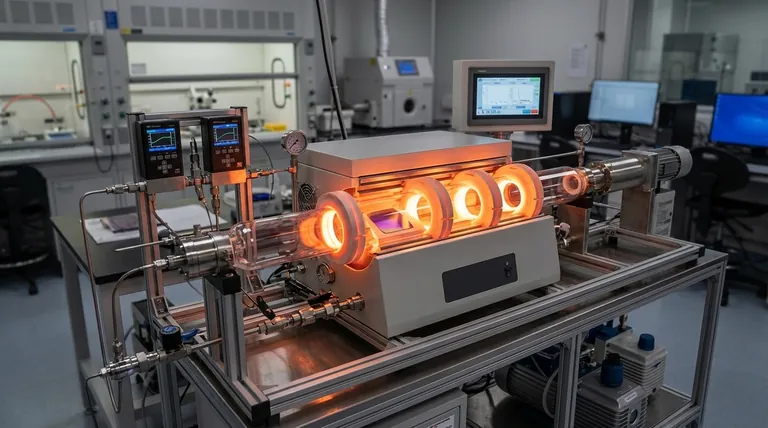

Visual Guide

References

- Xiaotian Li, Ruifen Dou. Controlling Twisted Angles in Directly Grown MoS <sub>2</sub> Bilayers via Tilt Grain Boundary Engineering. DOI: 10.1002/advs.202509280

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials