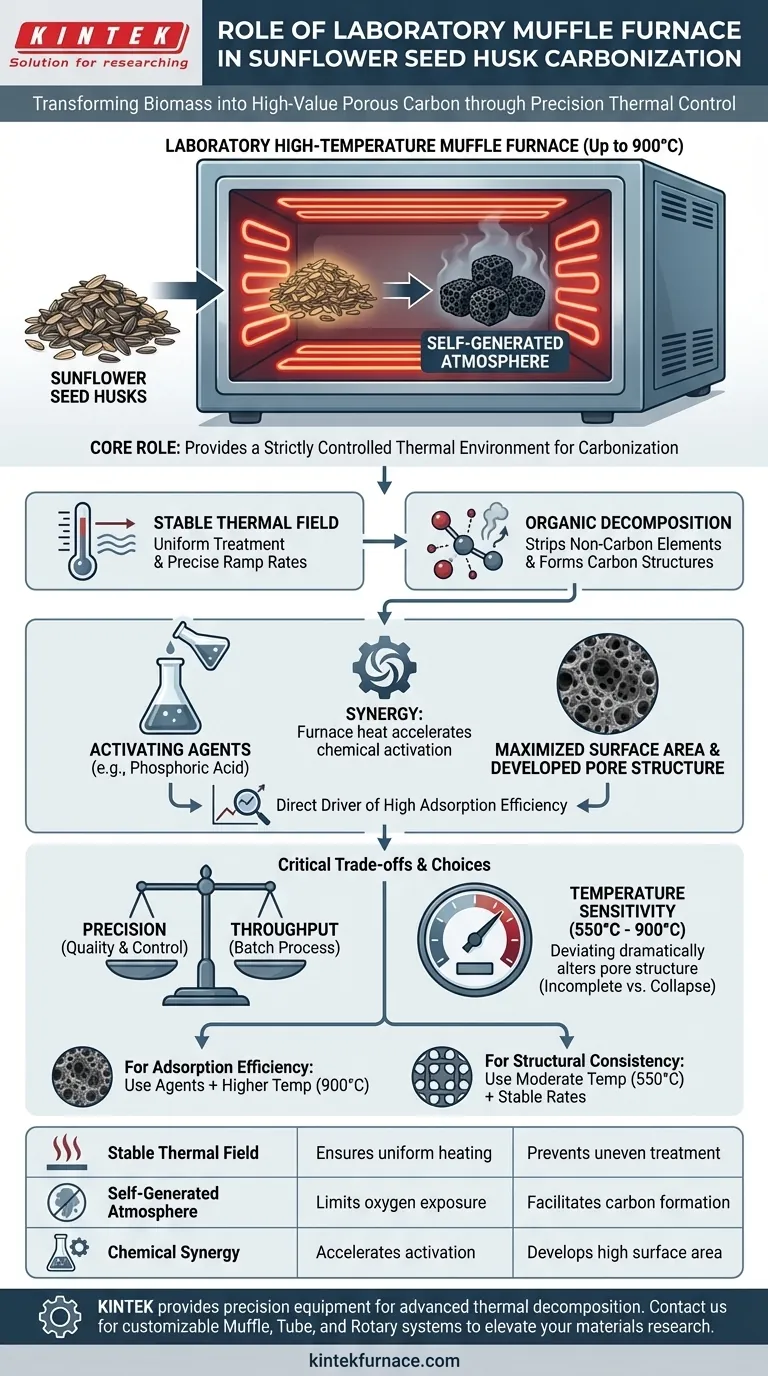

The primary role of a laboratory high-temperature muffle furnace is to provide a strictly controlled thermal environment that drives the carbonization of sunflower seed husks. By reaching temperatures up to 900°C, the furnace facilitates the decomposition of organic precursors in a self-generated atmosphere, transforming raw biomass into porous carbon material.

Core Takeaway The muffle furnace is not merely a heating source; it is a precision instrument that stabilizes the thermal field required for pyrolysis. This stability, combined with chemical activation, is essential for engineering the high specific surface area and complex pore structures that define effective activated carbon.

The Mechanism of Carbonization

Creating a Stable Thermal Field

The success of carbonization relies on thermal consistency. A high-temperature muffle furnace ensures a stable thermal field, which is critical for uniform treatment.

This stability prevents temperature fluctuations that could lead to uneven carbonization. It allows for precise ramp rates and hold times at temperatures as high as 550°C to 900°C.

Facilitating Organic Decomposition

Inside the furnace, the intense heat breaks down the complex organic structures of the sunflower seed husks. This process, known as thermal decomposition, strips away non-carbon elements.

As the organic precursors decompose, the furnace containment allows for a self-generated atmosphere. This specific environment prevents the husks from simply burning away to ash, instead favoring the formation of carbon structures.

Optimizing Material Properties

Synergy with Activating Agents

The furnace does not work in isolation; it amplifies the effects of chemical agents. When husks are treated with activating agents like phosphoric acid, the thermal environment accelerates the chemical interaction.

This combination promotes the development of highly developed pore structures. Without the precise heat of the muffle furnace, the chemical activation would fail to achieve the necessary structural changes.

Maximizing Surface Area

The ultimate goal of using this furnace is to engineer the physical architecture of the carbon. The controlled thermal treatment creates a vast network of pores.

This results in a material with a large specific surface area. This physical characteristic is the direct driver of high adsorption efficiency in the final product.

Understanding the Critical Trade-offs

Precision vs. Throughput

While a muffle furnace offers exceptional control over the thermal environment, it is typically a batch-process tool. The focus is on quality and precision rather than high-volume throughput.

Temperature Sensitivity

The "self-generated atmosphere" relies heavily on maintaining the exact target temperature. Deviating from the optimal temperature range (e.g., 550°C vs 900°C) dramatically alters the final pore structure.

If the temperature is too low, decomposition is incomplete; if it is uncontrolled, the pore structure may collapse, reducing adsorption capacity.

Making the Right Choice for Your Goal

To maximize the utility of a high-temperature muffle furnace for sunflower husk carbonization, consider your specific end-goals:

- If your primary focus is Adsorption Efficiency: Prioritize the use of activating agents (like phosphoric acid) combined with higher temperatures (up to 900°C) to maximize specific surface area.

- If your primary focus is Structural Consistency: Utilize the furnace's programmable ramp rates to ensure a stable thermal field at moderate temperatures (around 550°C) to facilitate uniform polycondensation.

By strictly controlling the thermal field and atmosphere, the muffle furnace turns agricultural waste into a high-value industrial adsorbent.

Summary Table:

| Process Element | Role in Carbonization | Impact on Material |

|---|---|---|

| Stable Thermal Field | Ensures uniform heating (550°C - 900°C) | Prevents uneven treatment and structural collapse |

| Self-Generated Atmosphere | Limits oxygen exposure during heating | Facilitates carbon structure formation over ash |

| Chemical Synergy | Accelerates phosphoric acid activation | Develops high specific surface area and micro-pores |

| Programmable Ramp Rates | Controls decomposition speed | Optimizes adsorption efficiency and polycondensation |

Elevate Your Materials Research with KINTEK

Are you looking to transform biomass into high-performance activated carbon? KINTEK provides the precision equipment necessary for advanced thermal decomposition. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are customizable to meet your unique carbonization and chemical activation requirements.

Our lab high-temperature furnaces ensure the stable thermal fields and atmospheric control required to maximize specific surface area and adsorption efficiency for your target customers. Contact us today to find the perfect furnace solution and leverage our technical expertise for your next project.

Visual Guide

References

- Alaa E. Ali, Hassan Shokry. Remediation of contaminated water using cellulose acetate membrane hybrid by sunflower seed shell–activated carbon. DOI: 10.1007/s13399-024-05326-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are common high-temperature applications of muffle furnaces in laboratories? Unlock Precision in Material Testing and Synthesis

- Why is a muffle furnace used for 1350°C Ti-Al-Nb heat treatment? Optimize Alloy Plasticity and Stress Relief

- What key components are used in vacuum muffle furnaces to ensure precise gas dispersion? Discover the MFC and BPR System

- What types of heating elements are used in muffle furnaces and their temperature ranges? Choose the Right Element for Your Lab

- What role does a muffle furnace play in the calcination of metal catalysts? Optimize Thermal Stability and Reactivity

- Why use a muffle furnace for AAS concrete testing? Achieve Precise Thermal Analysis for High-Temperature Performance

- Why is a high-temp muffle furnace required for graphene catalyst calcination? Achieve Precise Phase Transformation

- What is the design feature of the furnace chamber and frame in a muffle furnace? Discover the Key to Durability