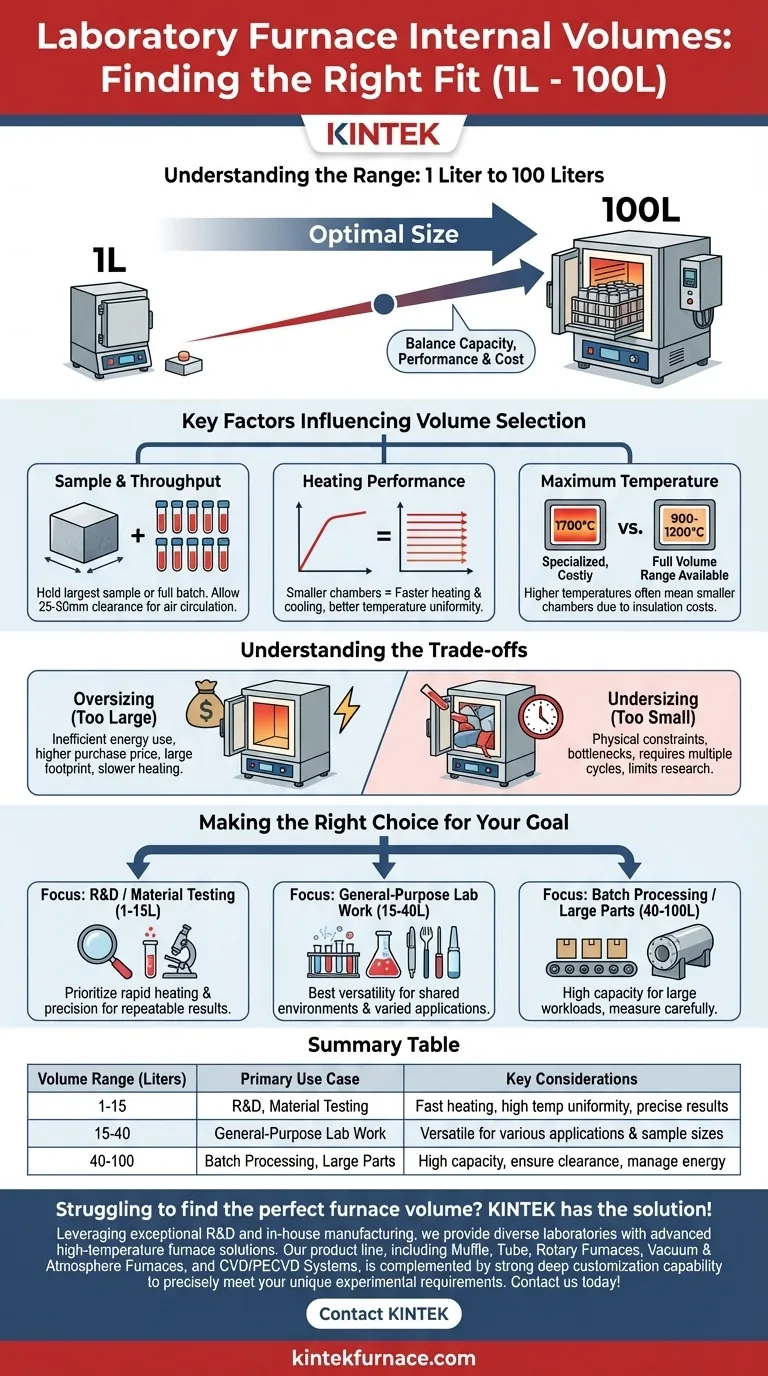

In short, the internal volume of a Laboratory Type Furnace typically ranges from 1 liter to 100 liters. This wide range exists because the optimal size is entirely dependent on the specific scientific or industrial process, balancing sample dimensions against performance requirements like heating speed and temperature uniformity.

Choosing the right furnace volume is less about the specification itself and more about understanding the fundamental trade-offs between capacity, thermal performance, and operational cost. The goal is to select the smallest chamber that can reliably accommodate your largest workload.

Key Factors Influencing Volume Selection

The internal volume of a furnace is not an isolated metric. It is directly linked to other critical performance characteristics that determine its suitability for a given task.

The Impact on Sample and Throughput

The most straightforward consideration is the physical size of the items you need to heat. Your furnace chamber must be large enough to hold your largest sample or a full batch of smaller items.

Always allow for adequate clearance—at least 25-50mm—around the sample. This ensures proper air circulation and prevents direct contact with heating elements or the thermocouple, which can lead to inaccurate temperature readings and uneven heating.

The Relationship with Heating Performance

Smaller furnace chambers generally offer superior thermal performance. With a lower thermal mass, they heat up and cool down faster than larger furnaces.

This smaller volume also makes it easier to achieve and maintain excellent temperature uniformity across the entire chamber, which is critical for sensitive research and quality control applications where every part of the sample must be at the same temperature.

The Connection to Maximum Temperature

While not a direct rule, there is often an inverse relationship between maximum temperature and volume. Furnaces designed for very high temperatures (e.g., 1700°C) require advanced, costly insulation and specialized heating elements.

To manage cost and technical complexity, these ultra-high temperature models are frequently built with smaller internal chambers focused on specific, high-value processes. The most common laboratory furnaces, operating between 900°C and 1200°C, are available across the full volume range.

Understanding the Trade-offs

Selecting a furnace based on volume involves a careful balance. Misjudging your needs can lead to inefficiency or operational constraints.

The Cost of Oversizing

Choosing a furnace that is too large for your typical application creates inefficiency. A larger chamber consumes significantly more energy to reach and maintain its setpoint temperature.

Furthermore, the initial purchase price is higher, and the furnace will occupy more valuable lab space. It may also have slower heat-up times than a properly sized model, reducing overall productivity for smaller tasks.

The Limitation of Undersizing

An undersized furnace presents an obvious physical limitation. It will prevent you from processing larger components or running larger batches, potentially creating a bottleneck in your workflow.

This can hinder future research possibilities or force you to run multiple, time-consuming cycles for a task that could have been completed in a single run with a larger unit.

Making the Right Choice for Your Goal

To select the correct furnace volume, begin by defining your primary operational need.

- If your primary focus is R&D or material testing: Prioritize a smaller furnace (e.g., 1-15 liters) that offers rapid heating and excellent temperature uniformity for precise, repeatable results on small samples.

- If your primary focus is general-purpose lab work: A mid-size furnace (e.g., 15-40 liters) offers the best versatility for a shared environment with a variety of applications and sample sizes.

- If your primary focus is batch processing or heat-treating large parts: Select a larger furnace (e.g., 40-100 liters) after carefully measuring your typical workload to ensure capacity without excessive oversizing.

Ultimately, the right furnace is the one whose chamber dimensions are deliberately matched to the demands of your specific process.

Summary Table:

| Volume Range (Liters) | Primary Use Case | Key Considerations |

|---|---|---|

| 1-15 | R&D, Material Testing | Fast heating, high temperature uniformity, precise results |

| 15-40 | General-Purpose Lab Work | Versatile for various applications and sample sizes |

| 40-100 | Batch Processing, Large Parts | High capacity, ensure adequate clearance, manage energy use |

Struggling to find the perfect furnace volume for your lab? KINTEK has the solution! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your lab's efficiency and performance with a tailored furnace!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More