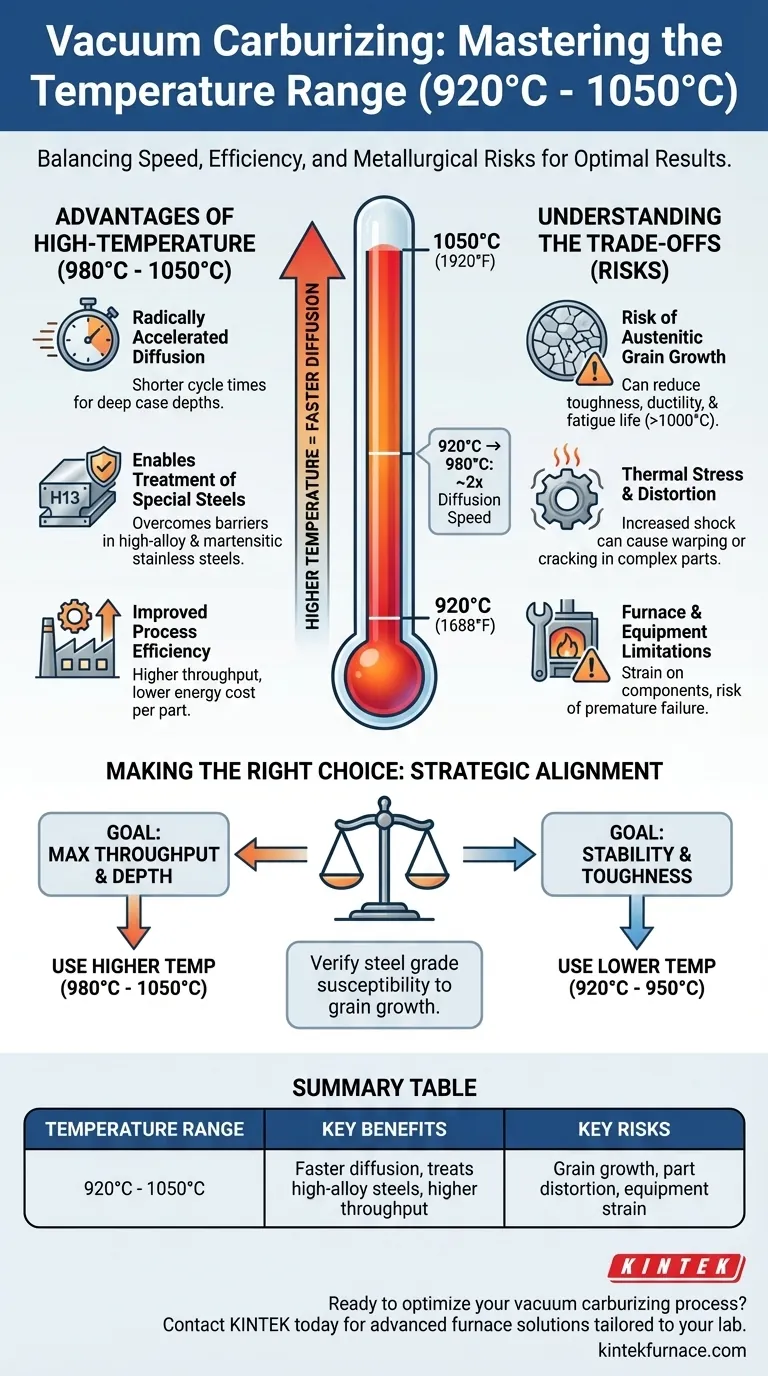

In vacuum carburizing, the typical operating temperature range extends from conventional levels around 920°C up to a maximum of 1050°C (1920°F). This broad range allows for significant process flexibility, with higher temperatures drastically accelerating the carburizing cycle. For example, increasing the temperature from 920°C to 980°C can effectively double the speed of carbon diffusion.

The ability to use high temperatures is a core advantage of vacuum carburizing, but it is not a universal solution. The optimal temperature is a strategic choice, balancing the need for speed and efficiency against the metallurgical risks of grain growth and part distortion.

The Advantage of High-Temperature Carburizing

The primary driver for pushing beyond conventional carburizing temperatures is speed. This has profound implications for both efficiency and material capability.

Radically Accelerated Diffusion

Heat is the engine of diffusion. By increasing the process temperature, the rate at which carbon atoms penetrate the steel surface increases exponentially.

This relationship means that achieving a deep case depth, which might take many hours at 920°C, can be accomplished in a fraction of the time at 980°C or higher. This directly translates to shorter cycle times.

Enabling Treatment for Special Steels

Many modern, high-performance alloys present challenges for traditional carburizing. Their high chromium content and other alloying elements can inhibit the absorption of carbon.

Vacuum carburizing at elevated temperatures provides the necessary energy to overcome these barriers. It is particularly effective for martensitic stainless steels, tool steels like H13, and other high-alloy grades where a hard, wear-resistant surface is required.

Improved Process Efficiency

Shorter cycle times lead directly to greater operational efficiency. A furnace can process more loads per day, increasing throughput and lowering the energy cost associated with each component. This makes high-temperature vacuum carburizing a highly economical choice for high-volume production.

Understanding the Trade-offs

While higher temperatures offer significant benefits, they also introduce critical metallurgical and mechanical trade-offs that must be managed.

The Risk of Austenitic Grain Growth

Holding steel at very high temperatures, especially above 1000°C, encourages the growth of austenitic grains within the material's microstructure.

Upon quenching, large grains can lead to reduced toughness, ductility, and fatigue life. This is a critical consideration for components subjected to high impact or cyclical loads.

Thermal Stress and Distortion

A wider temperature delta between the carburizing step and the quenching medium increases thermal shock.

This can lead to greater part distortion, which is a major concern for components with complex geometries or tight dimensional tolerances. In severe cases, it can even cause cracking.

Furnace and Equipment Limitations

Operating consistently at temperatures above 1000°C places significant strain on furnace components, such as heating elements and insulation.

Not all vacuum furnaces are designed or rated for continuous operation at the upper end of this temperature range. Pushing equipment beyond its design limits can lead to premature failure and costly downtime.

Making the Right Choice for Your Goal

Selecting the correct temperature is not about finding a single "best" number; it's about aligning the process parameters with your specific engineering objective.

- If your primary focus is maximum throughput and deep case depths: Utilize higher temperatures (980°C to 1050°C), but verify that your specific steel grade is not overly susceptible to detrimental grain growth.

- If your primary focus is treating high-alloy or stainless steels: Higher temperatures are often a prerequisite to achieve the necessary carbon absorption and carbide formation for effective surface hardening.

- If your primary focus is dimensional stability and component toughness: Operate in the more conventional lower range (920°C to 950°C) to minimize thermal stress and prevent excessive grain growth.

Ultimately, mastering vacuum carburizing lies in strategically selecting the temperature that best aligns with your material, component geometry, and final performance requirements.

Summary Table:

| Temperature Range | Key Benefits | Key Risks |

|---|---|---|

| 920°C - 1050°C | Faster diffusion, treats high-alloy steels, higher throughput | Grain growth, part distortion, equipment strain |

Ready to optimize your vacuum carburizing process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to enhance efficiency and achieve superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement