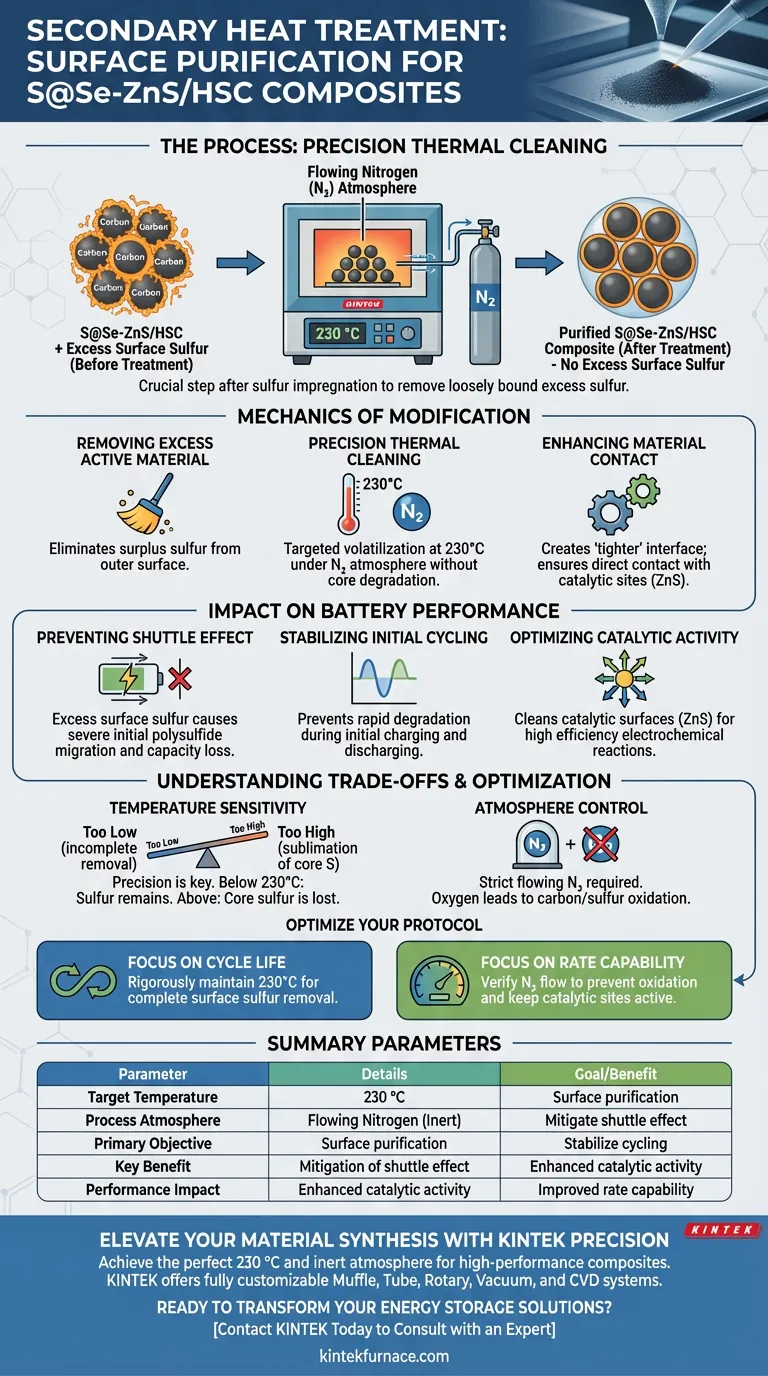

The secondary heat treatment functions as a critical surface purification step designed to optimize the electrochemical performance of the composite material. Occurring after sulfur impregnation, this process involves heating the material to 230 °C under a flowing nitrogen atmosphere to remove excess active sulfur adhering to the exterior of the carbon spheres.

This thermal treatment is essential for mitigating the "shuttle effect." By eliminating loosely bound surface sulfur, the process stabilizes the material and ensures intimate contact between the active components and the catalytic sites.

The Mechanics of Surface Modification

Removing Excess Active Material

The primary mechanical goal of this step is the removal of surplus sulfur. During the previous impregnation stage, excess active sulfur inevitably adheres to the outer surface of the carbon spheres.

Precision Thermal Cleaning

The specific temperature of 230 °C is chosen to target this surface sulfur without degrading the core composite. Under a flowing nitrogen atmosphere, the excess material is effectively volatilized or dislodged.

Enhancing Material Contact

Removing the interference layer of surface sulfur creates a "tighter" interface. This ensures the active materials are in direct physical contact with the catalytic sites inside the composite structure.

Impact on Battery Performance

Preventing the Shuttle Effect

The "shuttle effect" is a common failure mode where soluble polysulfides migrate within the battery, causing capacity loss. Excess surface sulfur is a major contributor to severe initial shuttle effects.

Stabilizing Initial Cycling

By removing the primary source of soluble polysulfides before the battery is even assembled, the material is stabilized. This prevents the rapid degradation often seen during the initial charging and discharging cycles.

Optimizing Catalytic Activity

For the catalytic sites (ZnS) to function, they must interact directly with the reactants. The heat treatment cleans the catalytic surfaces, ensuring high efficiency during electrochemical reactions.

Understanding the Trade-offs

Temperature Sensitivity

Precision is non-negotiable in this process. If the temperature drops significantly below 230 °C, surface sulfur will remain, compromising stability; if it rises too high, you risk sublimating the essential sulfur stored inside the pores.

Atmosphere Control

The reliance on a flowing nitrogen atmosphere adds complexity to the manufacturing process. Any introduction of oxygen during this heated phase could lead to the oxidation of the carbon spheres or the sulfur, ruining the composite.

Optimizing Your Synthesis Protocol

To ensure the highest quality S@Se-ZnS/HSC composite, align your process with your specific performance targets:

- If your primary focus is Cycle Life: Rigorously maintain the 230 °C setpoint to ensure complete removal of surface sulfur, which is the main driver of early capacity fading.

- If your primary focus is Rate Capability: Verify the flow rate of the nitrogen atmosphere to prevent oxidation, ensuring the catalytic sites remain active for fast ion transfer.

This secondary annealing is not merely a drying step; it is the final structural calibration required to transform a raw mixture into a stable, high-performance energy storage material.

Summary Table:

| Parameter/Goal | Details |

|---|---|

| Target Temperature | 230 °C |

| Process Atmosphere | Flowing Nitrogen (Inert) |

| Primary Objective | Surface purification (removing excess active sulfur) |

| Key Benefit | Mitigation of the "shuttle effect" and stabilization of cycling |

| Performance Impact | Enhanced catalytic activity and improved rate capability |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect 230 °C setpoint and maintaining a rigorous inert atmosphere is critical for high-performance composite materials. At KINTEK, we understand that precision is non-negotiable for battery research and advanced material science.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique laboratory needs. Whether you are scaling up S@Se-ZnS/HSC production or refining complex annealing protocols, our high-temp furnaces provide the thermal stability and atmosphere control required to eliminate the shuttle effect and optimize catalytic activity.

Ready to transform your raw mixtures into stable, high-performance energy storage solutions?

Contact KINTEK Today to Consult with an Expert

Visual Guide

References

- Sainan Luo, Limin Wu. Enhancing Conversion Kinetics through Electron Density Dual‐Regulation of Catalysts and Sulfur toward Room‐/Subzero‐Temperature Na–S Batteries. DOI: 10.1002/advs.202308180

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a vacuum or inert gas environment required for the preparation of polysulfide fluxes? Ensure Material Purity

- How are atmosphere furnaces applied in the preparation of optical materials? Enhance Clarity and Performance

- What role does an atmosphere box furnace play in material synthesis and preparation? Unlock Precision in Advanced Material Creation

- What is the primary purpose of a controlled atmosphere box furnace in heat treating? Unlock Precise Material Properties

- Why must a high-precision furnace be used for stress relief of Inconel 625 parts? Ensure 3D Print Dimensional Accuracy

- What high-temperature processes commonly use argon in furnaces? Essential Guide for Reactive Metals

- How does a heating furnace contribute to the simulated pre-oxidation of alloy powders? Optimize Your Material Research

- What are the different configurations available for inert atmosphere furnaces? Find Your Perfect Match for Heat Treatment