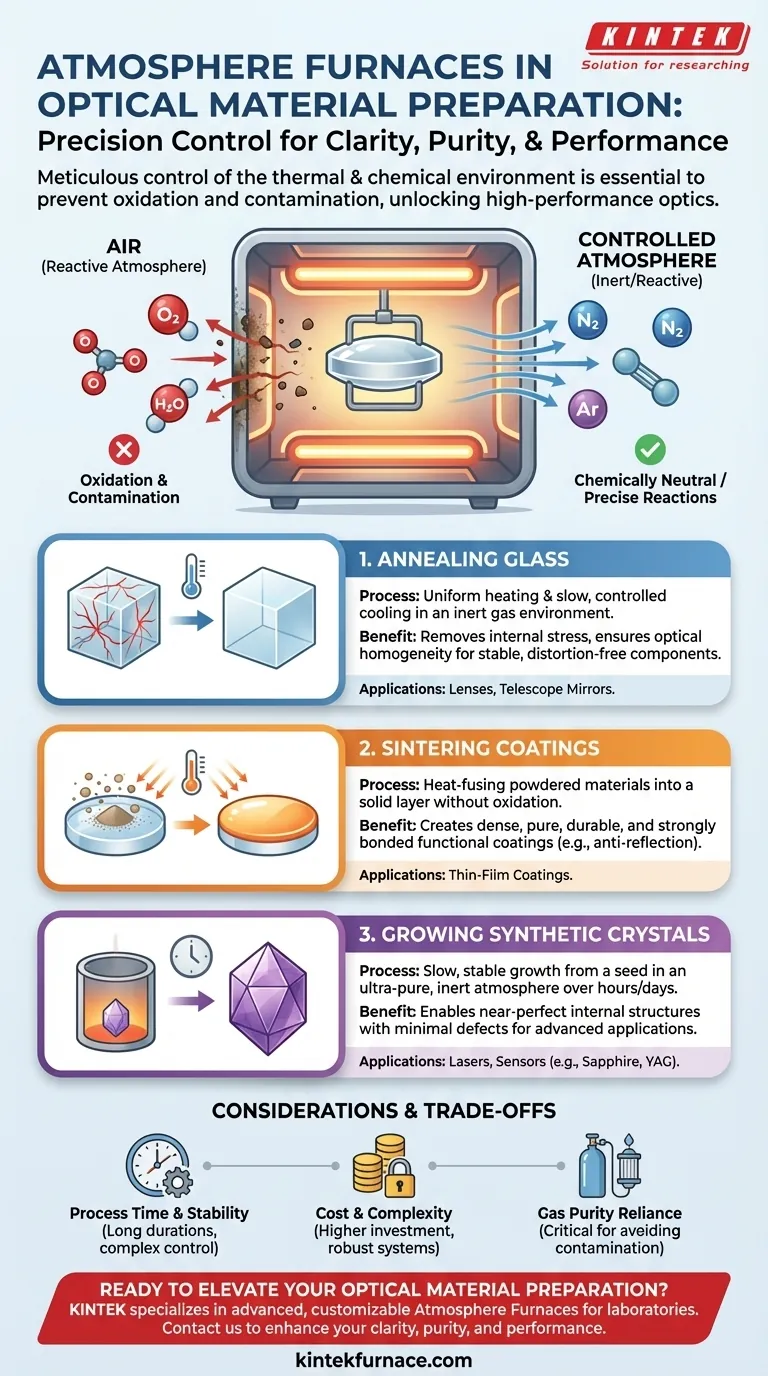

In essence, atmosphere furnaces are used in the preparation of optical materials for three primary applications: annealing glass to remove internal stress, sintering specialized coatings to enhance surface properties, and growing synthetic optical crystals in an ultra-pure environment. These processes are fundamental for creating high-performance optical components by providing precise control over the material’s final structure and purity.

The core value of an atmosphere furnace is not just heat, but the ability to meticulously control the chemical environment during heating. This control prevents oxidation and contamination, enabling the creation of optical materials with the exact clarity, uniformity, and performance characteristics required for advanced applications.

The Critical Role of a Controlled Atmosphere

The default atmosphere—air—is reactive. It contains approximately 21% oxygen and variable amounts of water vapor, both of which can be detrimental during the high-temperature processing of sensitive optical materials. An atmosphere furnace allows you to replace the air with a specific gas.

Preventing Oxidation and Contamination

At high temperatures, most materials readily react with oxygen. This oxidation can cause discoloration, create defects within the material's crystal lattice, and ruin the performance of a lens, mirror, or coating.

By filling the furnace with an inert gas like argon or nitrogen, oxygen is displaced. This creates a chemically neutral environment, preserving the purity and intended properties of the material.

Enabling Precise Chemical Reactions

In some advanced processes, a specific reactive gas is intentionally introduced. This allows for controlled chemical changes on the material's surface, such as doping silicon wafers for solar cells or creating specific surface chemistries that would be impossible in open air.

Key Applications in Optical Material Preparation

The ability to control the environment unlocks several critical manufacturing processes for optics. Each process uses the furnace to achieve a different outcome.

Annealing Glass for Stress Relief and Homogeneity

During initial manufacturing, glass and other optical blanks develop internal stresses. These stresses can cause microscopic inconsistencies in the refractive index, leading to image distortion, or even cause the component to crack over time.

Annealing is a process of heating the material to a specific temperature, holding it there, and then cooling it down very slowly. In an atmosphere furnace, this process ensures uniform heat distribution and prevents any surface reactions, resulting in a stable, stress-free component with uniform optical properties. This is critical for everything from eyeglass lenses to massive telescope mirrors.

Sintering High-Performance Coatings

Many optical components require thin-film coatings for functions like anti-reflection, scratch resistance, or filtering specific wavelengths of light. Sintering is a process that uses heat to fuse powdered coating materials into a solid, durable layer without melting them completely.

Performing this in an atmosphere furnace prevents the powdered materials from oxidizing before they can fuse, ensuring the final coating is dense, pure, and strongly bonded to the optical surface.

Growing Synthetic Optical Crystals

Advanced systems like lasers, high-speed sensors, and scientific instruments often rely on synthetic crystals (e.g., sapphire, YAG) with near-perfect internal structures. These crystals are "grown" over hours or days from a seed material in a highly controlled environment.

An atmosphere furnace provides the stable temperature and ultra-pure, inert atmosphere necessary for this slow growth. Any contamination from the air would be incorporated into the crystal lattice, creating performance-killing defects.

Understanding the Trade-offs

While essential, atmosphere furnaces introduce complexity and cost compared to simpler heating methods.

Process Time and Stability

Processes like annealing and crystal growth are inherently slow. A furnace run can last for many hours or even days. The system must maintain a perfectly stable temperature and gas environment throughout this entire duration, which requires sophisticated control systems.

Cost and Complexity

Atmosphere furnaces are significantly more expensive than standard air furnaces. They require robust seals to prevent leaks, advanced gas flow controllers, safety interlocks for handling flammable or inert gases, and often more complex power and temperature management systems.

Reliance on Gas Purity

The final result is only as good as the gas supplied to the furnace. Even small impurities in the nitrogen or argon supply can be enough to contaminate a sensitive batch of optical materials, making a high-purity gas supply a critical and ongoing operational cost.

Making the Right Choice for Your Goal

The specific process enabled by an atmosphere furnace is directly tied to the desired optical outcome.

- If your primary focus is optical clarity and long-term stability in glass components: Precision annealing in a controlled atmosphere is the essential step to eliminate internal stress and ensure homogeneity.

- If your primary focus is enhancing a surface with anti-reflection or durability: Controlled atmosphere sintering is the key to producing high-purity, high-density functional coatings.

- If your primary focus is creating specialized materials for lasers or advanced sensors: Growing synthetic crystals in an ultra-pure furnace atmosphere is the only method to achieve the required structural perfection.

Ultimately, mastering the preparation of modern optical materials is synonymous with mastering the control of their thermal processing environment.

Summary Table:

| Application | Key Benefit |

|---|---|

| Annealing Glass | Removes internal stress and ensures optical homogeneity |

| Sintering Coatings | Prevents oxidation for dense, pure surface layers |

| Growing Synthetic Crystals | Enables ultra-pure growth with minimal defects |

Ready to elevate your optical material preparation? KINTEK specializes in advanced high-temperature furnace solutions, including Atmosphere Furnaces, designed to meet the unique needs of laboratories. With our exceptional R&D and in-house manufacturing, we offer deep customization to ensure precise control over your thermal processes, enhancing clarity, purity, and performance. Contact us today to discuss how our products can transform your experiments and outcomes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance