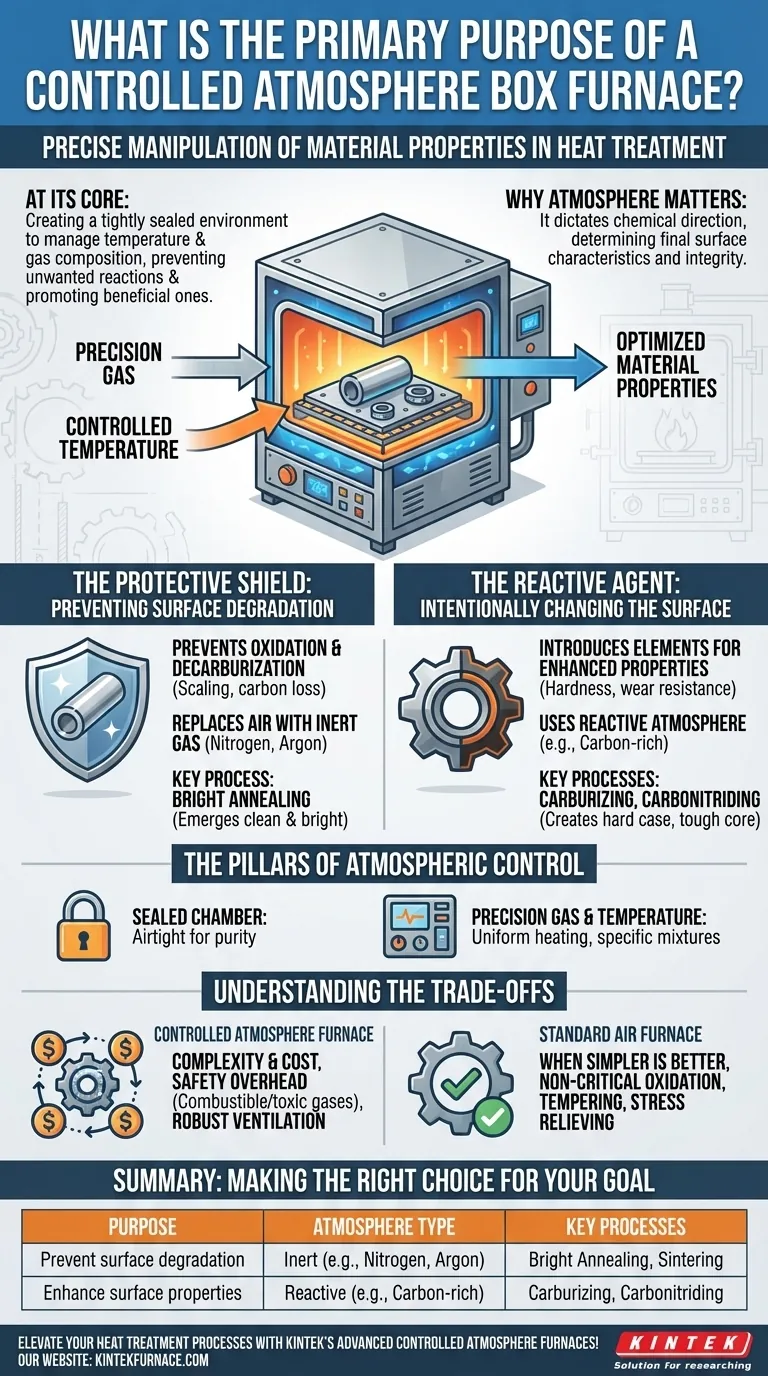

At its core, a controlled atmosphere box furnace allows for the precise manipulation of a material's properties during heat treatment. It achieves this by creating a tightly sealed environment where both the temperature and the chemical composition of the surrounding gas can be meticulously managed, preventing undesirable reactions while promoting beneficial ones.

The fundamental challenge in high-temperature heat treating is that hot metal is highly reactive with air. A controlled atmosphere furnace solves this by replacing the air with a specific gas mixture that acts as either a protective shield or a reactive agent, ensuring the final part meets exact specifications.

Why Atmosphere Matters More Than Just Heat

While temperature is the engine of heat treatment, the atmosphere is the steering wheel. It dictates the chemical direction of the process, determining the final surface characteristics and integrity of the component. This control serves two distinct purposes.

The Protective Shield: Preventing Surface Degradation

At elevated temperatures, most metals will readily react with the oxygen in the air. This leads to oxidation (scaling) and decarburization (the loss of carbon from the surface of steel), both of which compromise the material's strength, dimensions, and surface finish.

A controlled atmosphere furnace prevents this by purging the oxygen and replacing it with an inert or non-reactive gas, such as nitrogen or argon. This protects the part, allowing processes like bright annealing where the component emerges from the furnace as clean and bright as it went in.

The Reactive Agent: Intentionally Changing the Surface

Conversely, some processes require the atmosphere to be an active ingredient. The goal is to intentionally introduce elements into the surface of the material to enhance its properties, most commonly hardness and wear resistance.

In carburizing, for example, a carbon-rich atmosphere (like endothermic gas) is used. At high temperatures, carbon atoms from the gas diffuse into the surface of a steel part, creating a "case" of high-carbon steel that is extremely hard, while the core remains softer and tougher.

The Pillars of Atmospheric Control

Achieving these outcomes depends on the furnace's ability to precisely manage its internal environment. This capability is built on two key engineering principles.

The Sealed Chamber

The foundation of atmospheric control is an airtight furnace chamber. This design is critical for purging ambient air (specifically oxygen and water vapor) and maintaining the purity and pressure of the introduced process gas. Without a proper seal, contaminants would leak in and ruin the process.

Precision Gas and Temperature Management

These furnaces use advanced systems to meter specific gases or gas mixtures into the chamber. This is paired with a sophisticated temperature control system that ensures uniform heating. The synergy between precise atmospheric composition and stable temperature is what guarantees repeatable, high-quality results for processes like sintering, normalizing, and carbonitriding.

Understanding the Trade-offs

While powerful, a controlled atmosphere furnace is not the universal solution for all heat-treating needs. Understanding its limitations is key to making an informed decision.

Complexity and Cost

The systems required for sealing the chamber, managing gas flow, and ensuring safety make these furnaces significantly more complex and expensive than their standard air-breathing counterparts. The cost of the process gases themselves is also a major operational factor.

Safety and Operational Overhead

Many atmospheres, such as those rich in hydrogen or carbon monoxide, are combustible or toxic. Operating an atmosphere furnace requires strict safety protocols, specialized training, and robust ventilation and monitoring systems to mitigate risk.

When Simpler Is Better

For many applications where slight surface oxidation is acceptable or will be removed by subsequent machining, a simple air furnace is perfectly adequate. Processes like non-critical stress relieving or tempering often do not justify the cost and complexity of atmospheric control.

Making the Right Choice for Your Goal

Selecting the right furnace environment comes down to the desired final properties of the component.

- If your primary focus is preserving a pristine surface finish and bulk properties: You need a protective (inert) atmosphere to shield the part from oxidation, typical for bright annealing or sintering.

- If your primary focus is increasing surface hardness and wear resistance: You need a reactive atmosphere designed for case hardening processes like carburizing or carbonitriding.

- If your primary focus is general heat treatment where surface oxidation is non-critical: A more cost-effective standard air furnace is likely the most practical and efficient choice.

Ultimately, mastering heat treatment is about using the right atmosphere to unlock the full potential engineered into your material.

Summary Table:

| Purpose | Atmosphere Type | Key Processes |

|---|---|---|

| Prevent surface degradation | Inert (e.g., Nitrogen, Argon) | Bright Annealing, Sintering |

| Enhance surface properties | Reactive (e.g., Carbon-rich) | Carburizing, Carbonitriding |

Elevate your heat treatment processes with KINTEK's advanced controlled atmosphere furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Box, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced efficiency and repeatable results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening