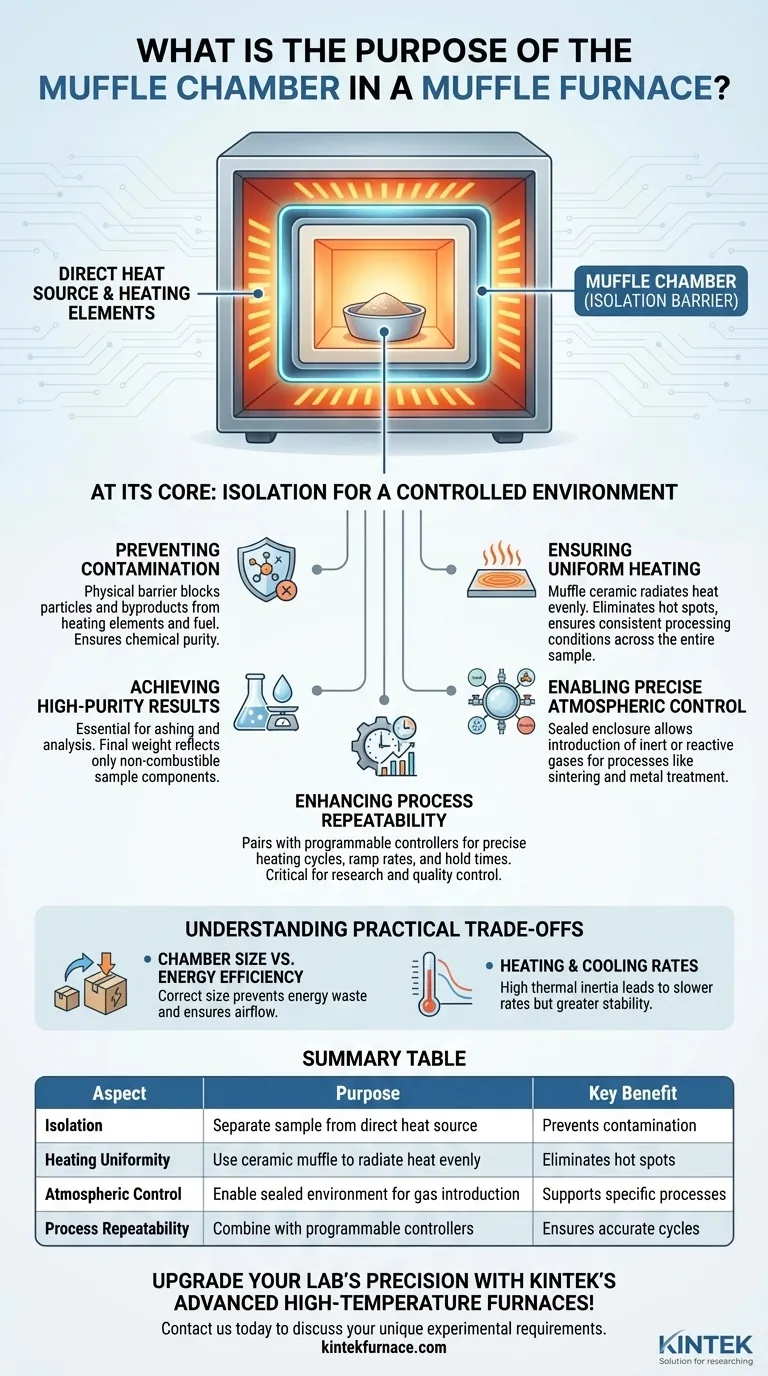

At its core, the purpose of a muffle chamber is to isolate the material being heated from the direct heat source. This separation creates a controlled, clean, and uniform heating environment, which is essential for sensitive scientific and industrial processes where contamination or uneven temperatures would compromise the results.

The muffle furnace isn't just a high-temperature oven; it's a precision instrument. The muffle chamber is the key component that transforms raw heat into a controlled environment, ensuring process purity and repeatability by shielding the sample from the heating elements and their byproducts.

The Core Principle: Isolation from the Heat Source

A muffle furnace's defining feature is this internal chamber, or "muffle." It acts as a protective barrier between the sample and the furnace's heating elements. This design delivers two primary benefits.

Preventing Contamination

In many high-temperature processes, the sample must remain chemically pure. The muffle chamber creates a physical barrier that prevents contamination from the heating source.

This is critical because heating elements can shed particles, and in fuel-fired furnaces, combustion byproducts like gas and soot would otherwise come into direct contact with the sample, altering its chemical composition and invalidating the results.

Ensuring Uniform Heating

The muffle, typically constructed from a high-temperature ceramic, absorbs energy from the surrounding heating elements and radiates it evenly throughout the chamber.

This indirect heating method eliminates "hot spots" that can occur when a sample is too close to a direct heating element. The result is a highly uniform temperature environment, ensuring the entire sample is processed under the exact same conditions.

The Functional Benefits of a Controlled Environment

The isolation provided by the muffle chamber enables a level of precision that is impossible with simpler ovens. This control is critical for achieving reliable, high-quality outcomes.

Achieving High-Purity Results

Processes like ashing require burning off all organic material to accurately measure the remaining inorganic content. The muffle chamber ensures that no external contaminants are introduced, so the final weight is exclusively that of the sample's non-combustible components.

Enabling Precise Atmospheric Control

Because the muffle chamber is a sealed enclosure, it allows for the manipulation of the internal atmosphere. This is vital for processes like sintering or certain metal treatments.

Operators can introduce inert gases to prevent oxidation or use specific reactive gases to achieve a desired chemical change in the material, something that would be impossible in an open heating system.

Enhancing Process Repeatability

Modern muffle furnaces pair the stable environment of the muffle chamber with sophisticated programmable controllers.

This combination allows users to define precise heating cycles, including ramp-up speeds, specific hold times at peak temperature, and controlled cooling periods. The result is a highly accurate and repeatable process, which is essential for both research and industrial quality control.

Understanding the Practical Trade-offs

While incredibly effective, the muffle design comes with considerations that you must balance against your specific needs.

Chamber Size vs. Energy Efficiency

The size of the muffle chamber directly impacts performance. A chamber that is too large for the sample wastes significant energy heating empty space.

Conversely, a chamber that is too small may not accommodate the workpiece or can restrict necessary airflow, leading to inefficient or failed processing.

Heating and Cooling Rates

The same ceramic material that provides excellent thermal uniformity also has high thermal inertia. This means muffle furnaces generally heat up and cool down more slowly than direct-heating ovens.

This stability is an advantage during processing but can be a drawback if you require rapid heating cycles.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on the level of precision and purity your process demands.

- If your primary focus is precise chemical analysis (e.g., ashing): The muffle chamber's ability to prevent contamination is its most critical feature.

- If your primary focus is materials processing (e.g., sintering, heat treating): The combination of uniform heating and the potential for atmospheric control makes a muffle furnace the superior choice.

- If your primary focus is simple drying or rapid heating: A standard laboratory oven without a muffle may be a faster and more energy-efficient solution, provided sample contamination is not a concern.

Ultimately, the muffle chamber is what elevates a furnace from a simple heat source to a tool for precise thermal processing.

Summary Table:

| Aspect | Purpose | Key Benefit |

|---|---|---|

| Isolation | Separate sample from direct heat source | Prevents contamination from heating elements and byproducts |

| Heating Uniformity | Use ceramic muffle to radiate heat evenly | Eliminates hot spots for consistent results |

| Atmospheric Control | Enable sealed environment for gas introduction | Supports processes like sintering and oxidation prevention |

| Process Repeatability | Combine with programmable controllers | Ensures accurate, repeatable heating cycles for quality control |

Upgrade your lab's precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met for cleaner, more uniform heating. Contact us today to discuss how our products can enhance your thermal processing efficiency and reliability!

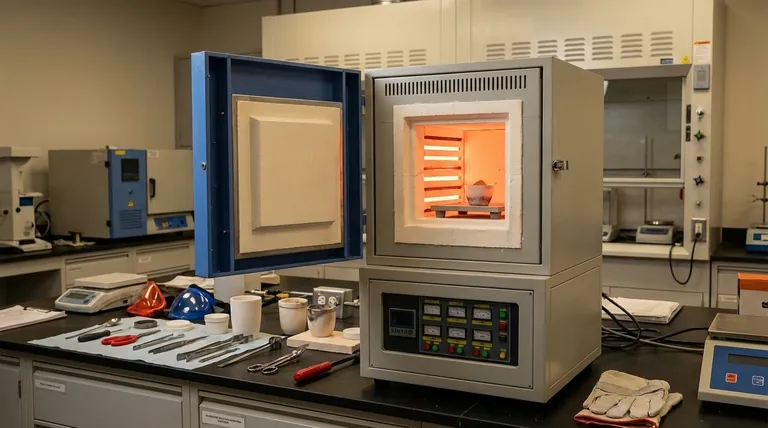

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment