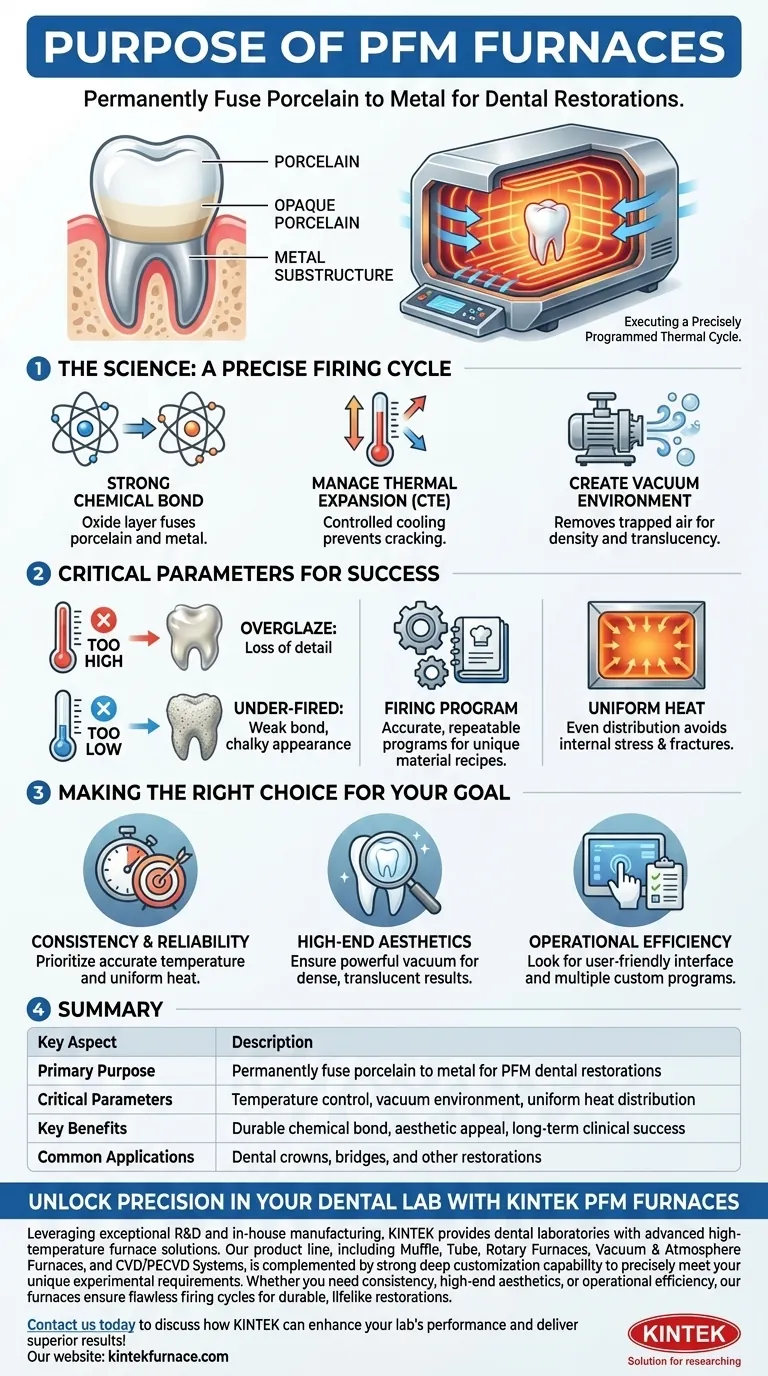

At its core, a PFM furnace is designed for one critical task: to permanently fuse layers of porcelain onto a metal substructure, creating a Porcelain-Fused-to-Metal (PFM) dental restoration. This process requires an environment of extreme precision, as the furnace must execute a perfect firing cycle to ensure the final crown or bridge is both aesthetically pleasing and structurally sound for long-term clinical success.

The true purpose of a PFM furnace is not simply to heat materials, but to execute a precisely programmed thermal cycle. This controlled process manages expansion and contraction, creating a stress-free, durable chemical bond between two fundamentally different materials—porcelain and metal.

The Science of a Successful Firing Cycle

A PFM furnace is far more than a simple oven. It is a sophisticated instrument engineered to control multiple environmental variables simultaneously, each one critical to the final quality of the restoration.

Achieving the Chemical Bond

The primary function of the firing cycle is to heat the metal and porcelain to a specific temperature range. At this point, an oxide layer forms on the metal substructure, which then chemically bonds with the first layer of opaque porcelain. This fusion is the foundation of the PFM restoration's strength.

Managing Thermal Expansion

Metal and porcelain expand and contract at different rates when heated and cooled. This property is known as the Coefficient of Thermal Expansion (CTE). A PFM furnace's programmed, controlled cooling phase is vital to manage this discrepancy and prevent the porcelain from cracking or chipping under stress as it cools.

Creating a Vacuum Environment

Most firing cycles are performed under a vacuum. The furnace’s vacuum pump removes air from the heating chamber (the muffle), which pulls trapped air out of the porcelain particles. This results in a denser, stronger, and more translucent final restoration, free from the porosities that weaken the material and compromise aesthetics.

Understanding the Critical Parameters

The success of a PFM restoration hinges on the furnace’s ability to flawlessly control its internal environment. Failure to manage these parameters leads directly to costly remakes and inconsistent results.

The Risk of Incorrect Temperatures

Even minor deviations from the target temperature can ruin a restoration. If the temperature is too high, the porcelain can "overglaze," losing its shape, surface texture, and anatomical detail. If it is too low, the porcelain will be under-fired, resulting in a weak chemical bond and a porous, chalky appearance.

The Importance of the Firing Program

Every porcelain system has a unique "recipe"—a specific firing program detailing temperatures, hold times, heating/cooling rates, and vacuum levels. A reliable PFM furnace must be accurately programmable to follow these diverse schedules with perfect repeatability.

The Need for Uniform Heat

The furnace's heating chamber, known as the muffle, is designed to distribute heat evenly. Cold spots within the chamber will cause uneven firing across the restoration, creating internal stresses that can lead to fractures long after the crown has been seated in the patient's mouth.

Making the Right Choice for Your Goal

Selecting or operating a PFM furnace requires understanding your primary objectives, as different features support different outcomes.

- If your primary focus is consistency and reliability: Prioritize a furnace with superior temperature accuracy and a high-quality muffle that guarantees uniform heat distribution for repeatable results.

- If your primary focus is high-end aesthetics: Ensure the furnace has a powerful, responsive vacuum system to produce dense, void-free porcelain with natural-looking translucency.

- If your primary focus is operational efficiency: Look for a furnace with a user-friendly interface and the capacity to store a large number of custom programs, minimizing setup time between different cases.

Ultimately, a PFM furnace is the instrument that transforms raw materials into a durable and lifelike dental restoration.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Purpose | Permanently fuse porcelain to metal for PFM dental restorations |

| Critical Parameters | Temperature control, vacuum environment, uniform heat distribution |

| Key Benefits | Durable chemical bond, aesthetic appeal, long-term clinical success |

| Common Applications | Dental crowns, bridges, and other restorations |

Unlock Precision in Your Dental Lab with KINTEK PFM Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Whether you need consistency, high-end aesthetics, or operational efficiency, our furnaces ensure flawless firing cycles for durable, lifelike restorations.

Contact us today to discuss how KINTEK can enhance your lab's performance and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision