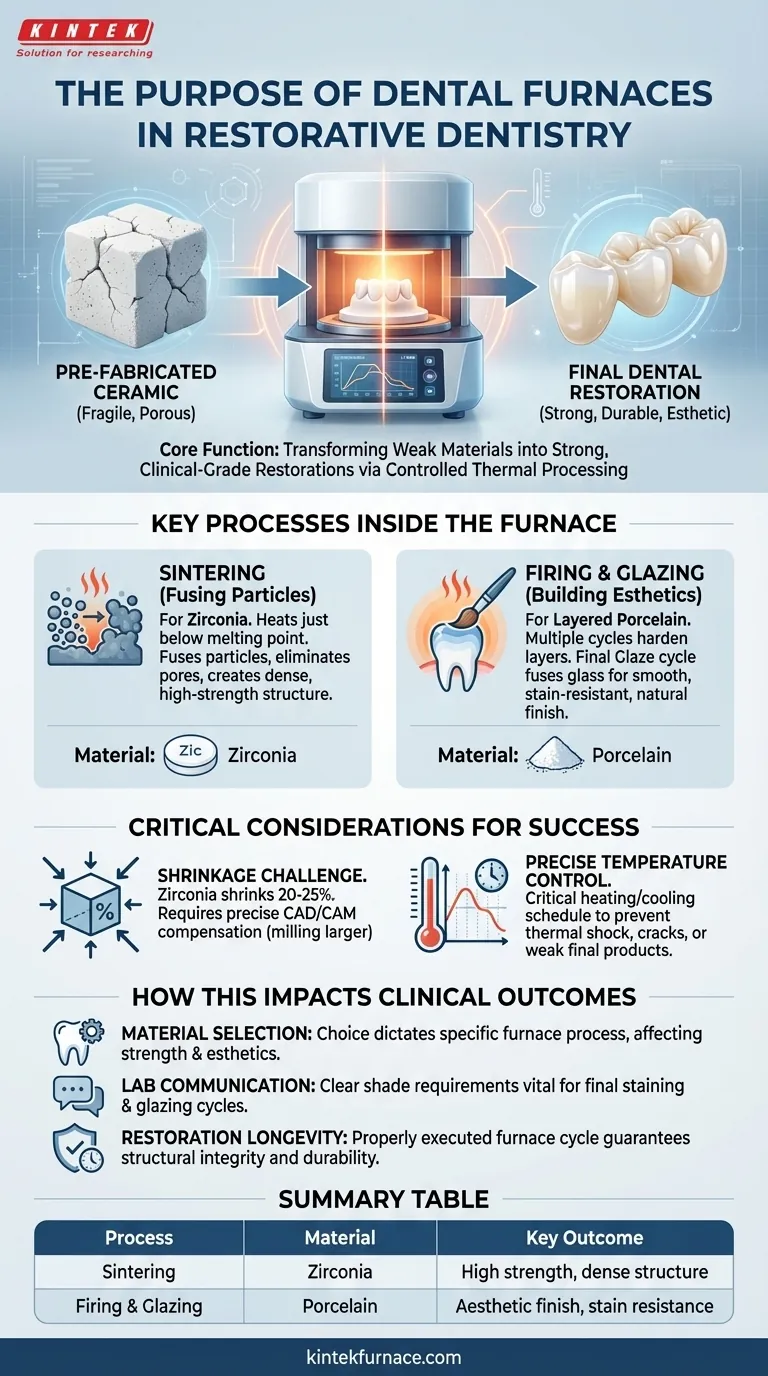

In short, the purpose of a dental furnace is to transform weak, pre-fabricated ceramic materials into strong, durable, and aesthetically pleasing final dental restorations. It uses precisely controlled heat to harden materials like crowns, bridges, and veneers so they can withstand the functional forces of the human mouth.

The dental furnace is the critical link between a digitally designed or manually shaped restoration and a clinically successful one. It doesn't just heat the material; it fundamentally re-engineers its microstructure, converting it from a fragile, chalk-like state into a dense, high-strength final product.

The Core Function: From Fragile Form to Final Restoration

A common misunderstanding is that dental furnaces simply "bake" or "dry" a restoration. The reality is a far more sophisticated materials science process.

The Problem with Unprocessed Ceramics

Raw dental ceramics, whether milled from a block of zirconia or layered as porcelain powder, lack the structural integrity for clinical use.

In this initial state, the material is porous and brittle. It cannot withstand the significant chewing forces present in the oral cavity.

The Solution: Thermal Transformation

The furnace applies a highly specific, pre-programmed temperature cycle. This controlled heating process initiates a physical and chemical transformation within the material.

This is what gives the final crown, bridge, or veneer its required strength, stability, color, and translucency.

Key Processes Inside the Furnace

Different materials require different thermal processes, but most fall into two primary categories that occur within a dental furnace.

Sintering: Fusing Particles into a Solid Mass

Sintering is the primary process for materials like zirconia. The furnace heats the material to a very high temperature, just below its melting point.

This intense heat causes the individual particles of the material to fuse, eliminating the pores between them and creating a dense, solid, and incredibly strong structure. Sintering furnaces use specialized heating elements, like molybdenum disilicide, to reliably reach these extreme temperatures.

Firing & Glazing: Building Aesthetics and Sealing the Surface

For layered restorations like porcelain veneers or crowns, the furnace is used for multiple "firing" cycles. Each layer of porcelain powder is applied and then fired to harden it before the next is added.

The final cycle is often a "glaze" firing, where a thin layer of glass is fused to the surface. This creates a smooth, stain-resistant, and natural-looking finish that mimics the luster of real tooth enamel.

Understanding the Critical Considerations

Executing these processes correctly is a matter of extreme precision. Failure to do so results in a failed restoration.

The Challenge of Shrinkage

During sintering, materials like zirconia undergo significant and predictable shrinkage, often as much as 20-25%.

This is not a flaw, but a fundamental property of the process. Dental technicians and CAD/CAM software must compensate for this by milling the initial "green state" restoration at a proportionally larger size.

The Need for Precise Temperature Control

The success of the restoration depends entirely on the furnace's ability to follow a precise heating and cooling schedule.

Ramping the temperature up too quickly can cause thermal shock and cracks. Holding it at the wrong peak temperature or for the wrong duration can result in a weak or discolored restoration. This is why modern dental furnaces are sophisticated, programmable devices.

How This Knowledge Impacts Clinical Outcomes

Understanding the role of the furnace is not just for lab technicians; it provides crucial context for the entire clinical team.

- If your primary focus is material selection: Understand that your choice (e.g., monolithic zirconia vs. layered porcelain) dictates the specific furnace process, which directly impacts the final restoration's strength and esthetics.

- If your primary focus is lab communication: Clearly communicating shade requirements is vital, as the lab technician uses final staining and glazing cycles in the furnace to achieve the desired aesthetic outcome.

- If your primary focus is ensuring restoration longevity: Appreciate that a properly executed furnace cycle is the single most important step in guaranteeing the restoration's structural integrity and ability to withstand long-term oral forces.

Ultimately, the dental furnace is the critical instrument that transforms a dental professional's design into a durable, functional, and beautiful reality for the patient.

Summary Table:

| Process | Material | Key Outcome |

|---|---|---|

| Sintering | Zirconia | High strength, dense structure |

| Firing & Glazing | Porcelain | Aesthetic finish, stain resistance |

Elevate your dental lab's capabilities with KINTEK's advanced dental furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, tailored to your unique needs through deep customization. Achieve precise sintering and firing for durable, beautiful restorations—contact us today to discuss how we can enhance your workflow and outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision