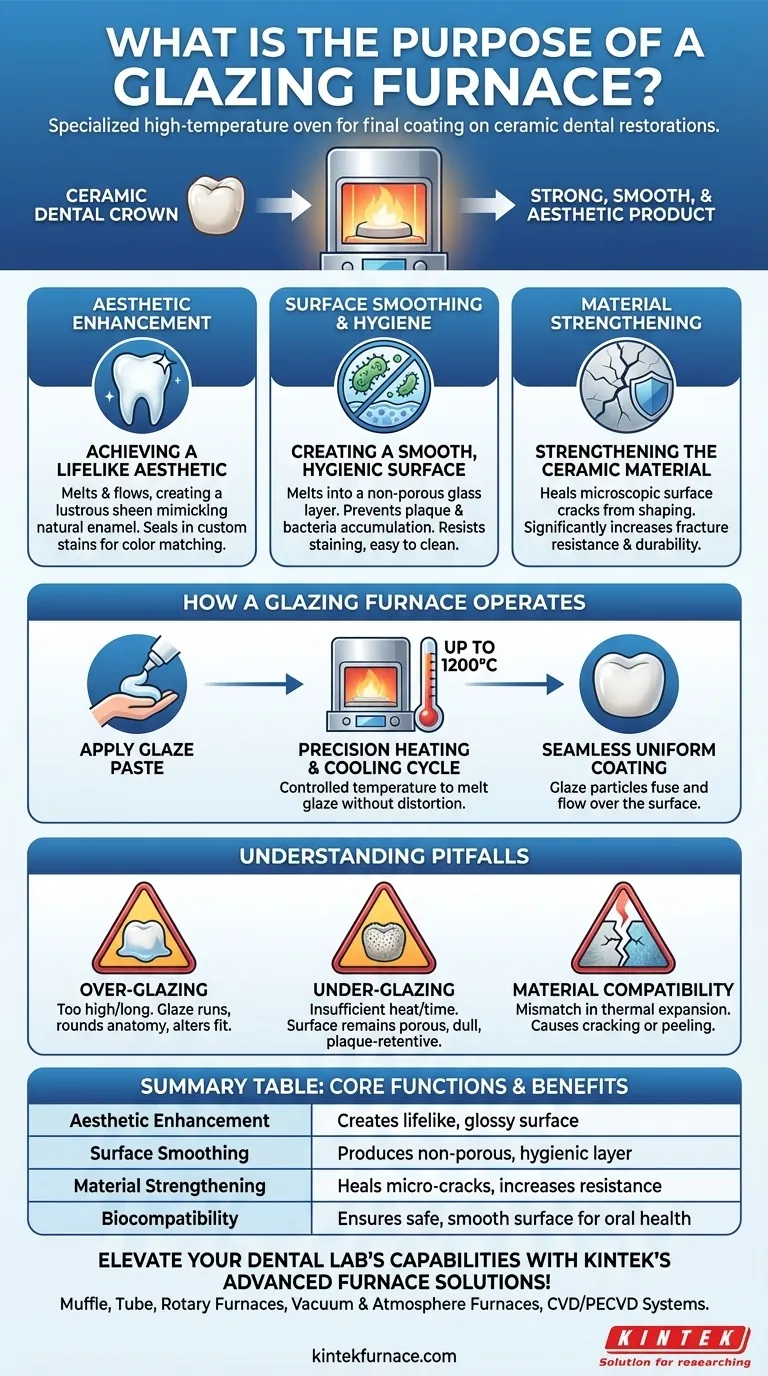

In the context of dental technology, a glazing furnace is a specialized high-temperature oven used to apply a final, glass-like coating to ceramic dental restorations. This process, known as glazing, is the critical final step after a crown, bridge, or veneer has been milled or built, creating a strong, smooth, and aesthetically pleasing final product that mimics a natural tooth.

The purpose of a glazing furnace extends beyond simple aesthetics. It is a crucial tool for transforming a porous, shaped ceramic into a final, non-porous, and durable restoration with enhanced strength and biocompatibility.

The Core Functions of Glazing

A glazing furnace performs several critical functions simultaneously during its firing cycle. Understanding these functions reveals why glazing is a non-negotiable step in producing high-quality ceramic restorations.

Achieving a Lifelike Aesthetic

The most visible purpose of glazing is to create a beautiful restoration. The glaze material melts and flows over the ceramic, creating a lustrous sheen that mimics the natural translucency and gloss of tooth enamel.

This process also seals in any external stains applied by the technician to match the specific color variations of the patient's surrounding teeth.

Creating a Smooth, Hygienic Surface

An unglazed ceramic restoration has a porous, slightly rough surface at a microscopic level. The furnace melts the glaze into a vitrified, non-porous glass layer.

This incredibly smooth surface is crucial for oral hygiene. It prevents the accumulation of plaque and bacteria and resists staining from food and drink, making the restoration easier for the patient to keep clean.

Strengthening the Ceramic Material

Perhaps the most important and least understood function is strengthening the restoration. The process of shaping and grinding a ceramic crown can introduce microscopic surface cracks.

The controlled heating and cooling cycle within the glazing furnace effectively "heals" these micro-cracks. This significantly increases the final fracture resistance and long-term durability of the restoration once it's in the patient's mouth.

How a Glazing Furnace Operates

While often used interchangeably with the broader term "ceramic furnace," a glazing cycle is a specific program focused on the final surface treatment.

Precision Temperature Control

Glazing furnaces are defined by their precise control over temperature. They execute pre-programmed heating cycles that can reach up to 1200°C (2192°F).

The furnace must raise and lower the temperature at a specific rate to properly melt the glaze without causing thermal shock or distortion to the underlying ceramic core.

The Firing Process

First, a technician applies a thin layer of glaze paste or powder to the shaped restoration. The restoration is then placed into the furnace.

As the furnace heats up, the glaze particles fuse together and flow, creating a seamless, uniform coating over the entire surface before being cooled in a controlled manner.

Understanding the Trade-offs and Pitfalls

Achieving a perfect glaze requires skill and precision. The furnace is a tool that must be used correctly to avoid compromising the final product.

The Risk of Over-Glazing

If the temperature is too high or the holding time is too long, the glaze can become too fluid. This can cause it to "run," which rounds out the sharp, functional anatomy (cusps and ridges) of the tooth and can alter the fit of the restoration.

The Problem of Under-Glazing

Conversely, insufficient heat or time will result in an incomplete glaze. The surface will remain porous and rough, defeating the purpose of the procedure and leading to staining, plaque retention, and a dull appearance.

Material Compatibility

Not all glazes work with all ceramics. The glaze material must have a coefficient of thermal expansion that is compatible with the core ceramic (e.g., zirconia, lithium disilicate). A mismatch can cause the glaze to crack or peel off over time.

Making the Right Choice for Your Goal

The glazing furnace is the tool that delivers the final quality of any ceramic restoration. Properly executing the glazing cycle is essential for meeting clinical and patient demands.

- If your primary focus is aesthetics: The glazing process is what seals in custom stains and creates the vital, natural luster that makes a restoration indistinguishable from a real tooth.

- If your primary focus is longevity: The heat cycle of the furnace is critical for healing surface micro-cracks, significantly increasing the restoration's overall fracture strength.

- If your primary focus is biocompatibility and hygiene: The furnace creates a vitrified, ultra-smooth surface that resists plaque accumulation, ensuring the long-term health of the surrounding gum tissue.

Ultimately, the glazing furnace is what transforms a technically correct restoration into a clinically successful one.

Summary Table:

| Function | Key Benefit |

|---|---|

| Aesthetic Enhancement | Creates a lifelike, glossy surface that mimics natural tooth enamel |

| Surface Smoothing | Produces a non-porous, hygienic layer to prevent plaque and staining |

| Material Strengthening | Heals micro-cracks, increasing fracture resistance and durability |

| Biocompatibility | Ensures a safe, smooth surface for long-term oral health |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, ensuring superior performance for ceramic restorations. Contact us today to discuss how our furnaces can enhance your workflow and deliver durable, aesthetic results for your patients!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations