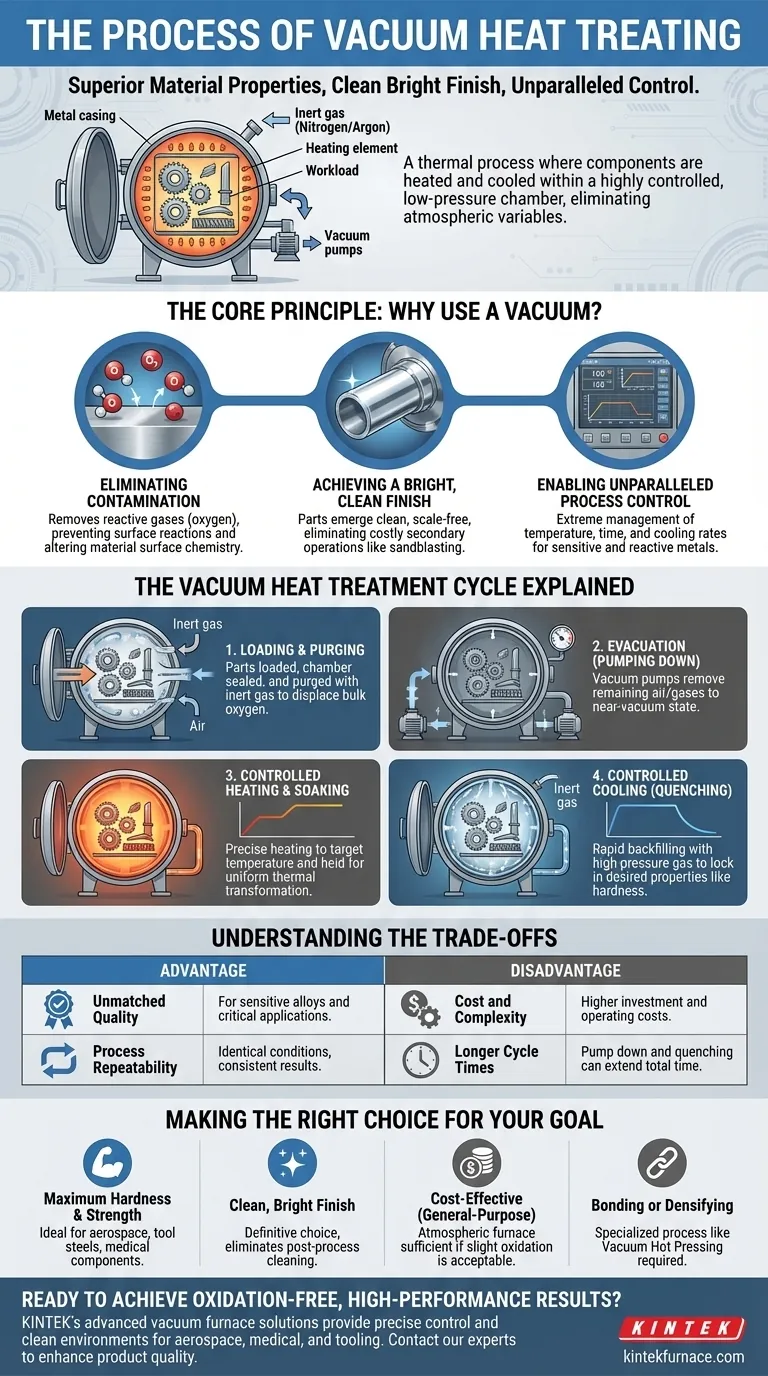

In essence, vacuum heat treating is a thermal process where metal components are heated and cooled within a highly controlled, low-pressure chamber. By using powerful pumps to remove air and its reactive gases—primarily oxygen—the process prevents oxidation and other surface reactions that occur during high-temperature treatment, resulting in superior material properties and a clean, bright finish.

The true value of vacuum heat treating isn't merely achieving a shiny surface; it is the unparalleled process control it offers. By eliminating atmospheric variables, it allows for the precise manipulation of a material's internal structure to meet the most demanding performance specifications.

The Core Principle: Why Use a Vacuum?

Heat treating fundamentally changes a material's microstructure to achieve desired properties like hardness or ductility. Performing this in a vacuum elevates the quality and predictability of the outcome.

Eliminating Atmospheric Contamination

At high temperatures, metals readily react with oxygen in the air, forming a brittle, discolored layer of oxide scale. A vacuum removes the oxygen, preventing this reaction entirely.

This ensures the material's surface chemistry remains unaltered, which is critical for high-performance applications.

Achieving a Bright, Clean Finish

The direct result of preventing oxidation is a part that emerges from the furnace with a clean, bright, and scale-free surface.

This often eliminates the need for costly and time-consuming secondary operations like sandblasting, pickling, or grinding.

Enabling Unparalleled Process Control

A vacuum chamber is a perfectly contained environment. This allows for extremely precise management of temperature, time, and cooling rates without interference from atmospheric fluctuations.

This level of control is essential for processing highly sensitive or reactive metals, such as titanium and specialty aerospace alloys.

The Vacuum Heat Treatment Cycle Explained

While specific parameters vary by material, the process follows a consistent and meticulously controlled sequence.

1. Loading and Purging

Parts are loaded into the furnace, which is then sealed airtight. The chamber is often purged with an inert gas, like nitrogen, to displace the bulk of the oxygen before the vacuum pumps engage.

2. Evacuation (Pumping Down)

A system of vacuum pumps removes the inert gas and any remaining air, reducing the internal pressure to a near-vacuum state. The specific vacuum level required depends on the material being treated.

3. Controlled Heating and Soaking

The furnace heats the material to a precise target temperature. The parts are held at this temperature for a specified period—known as the "soak"—to ensure the thermal transformation occurs uniformly throughout the entire component.

4. Controlled Cooling (Quenching)

Cooling is as critical as heating. To achieve desired hardness, the chamber is rapidly backfilled with a high-pressure inert gas (such as nitrogen or argon) to cool the parts at a controlled rate. For other processes like annealing, the parts may be cooled much more slowly inside the furnace.

Understanding the Trade-offs

Vacuum heat treating offers superior results, but it's important to understand its position relative to other methods.

Advantage: Unmatched Quality

For sensitive alloys and applications where surface integrity is non-negotiable (e.g., aerospace, medical implants), the quality provided by vacuum processing is unmatched.

Advantage: Process Repeatability

The digitally controlled and sealed environment ensures that every cycle runs under identical conditions, leading to highly consistent and repeatable results batch after batch.

Disadvantage: Cost and Complexity

Vacuum furnaces represent a significant capital investment and have higher operating costs compared to conventional atmospheric furnaces due to the pumps, seals, and complex control systems.

Disadvantage: Longer Cycle Times

The time required to pump the chamber down to a deep vacuum and then backfill for quenching can make the total process time longer than some atmospheric heat-treating methods.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your material requirements, performance goals, and budget.

- If your primary focus is maximum hardness and strength in sensitive alloys: The precise control and inert environment of vacuum treating are essential for aerospace, tool steels, and medical components.

- If your primary focus is a clean, bright finish with no surface oxidation: Vacuum treating is the definitive choice, eliminating the need for post-process cleaning.

- If your primary focus is cost-effective treatment for general-purpose steels: A traditional atmospheric furnace may be sufficient if slight surface oxidation is acceptable and can be removed later.

- If your primary focus is bonding or densifying materials: A specialized process like vacuum hot pressing, which combines heat, vacuum, and mechanical pressure, is the appropriate technology.

By understanding these core principles and trade-offs, you can confidently specify the most effective and efficient heat treatment for your project's unique needs.

Summary Table:

| Process Step | Key Action | Primary Outcome |

|---|---|---|

| Loading & Purging | Parts loaded; chamber purged with inert gas | Removes bulk oxygen to protect parts |

| Evacuation | Vacuum pumps remove air and gases | Creates a near-oxygen-free environment |

| Heating & Soaking | Precise heating to target temperature for a set time | Uniformly transforms the material's microstructure |

| Controlled Cooling | Rapid gas quenching or slow furnace cooling | Locks in desired properties like hardness or ductility |

Ready to achieve oxidation-free, high-performance results with your heat treatment?

KINTEK's advanced vacuum furnace solutions provide the precise control and clean environment necessary for processing sensitive alloys in aerospace, medical, and tooling applications. Our expertise in high-temperature furnace design and deep customization ensures your unique thermal processing requirements are met with unmatched consistency.

Contact our experts today to discuss how our vacuum heat treating technology can enhance your product quality and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion