At its core, a dental ceramic furnace is a specialized, high-temperature oven used to transform raw or partially processed ceramic materials into strong, durable, and aesthetically pleasing dental restorations. It executes highly specific heating cycles to trigger physical and chemical changes in materials like porcelain and zirconia, turning them into finished crowns, bridges, or veneers.

The crucial function of a dental furnace is not merely heating, but precisely controlling a material's transformation. It is a precision instrument that ensures every restoration achieves its designed strength, fit, and appearance through processes like firing, sintering, and crystallization.

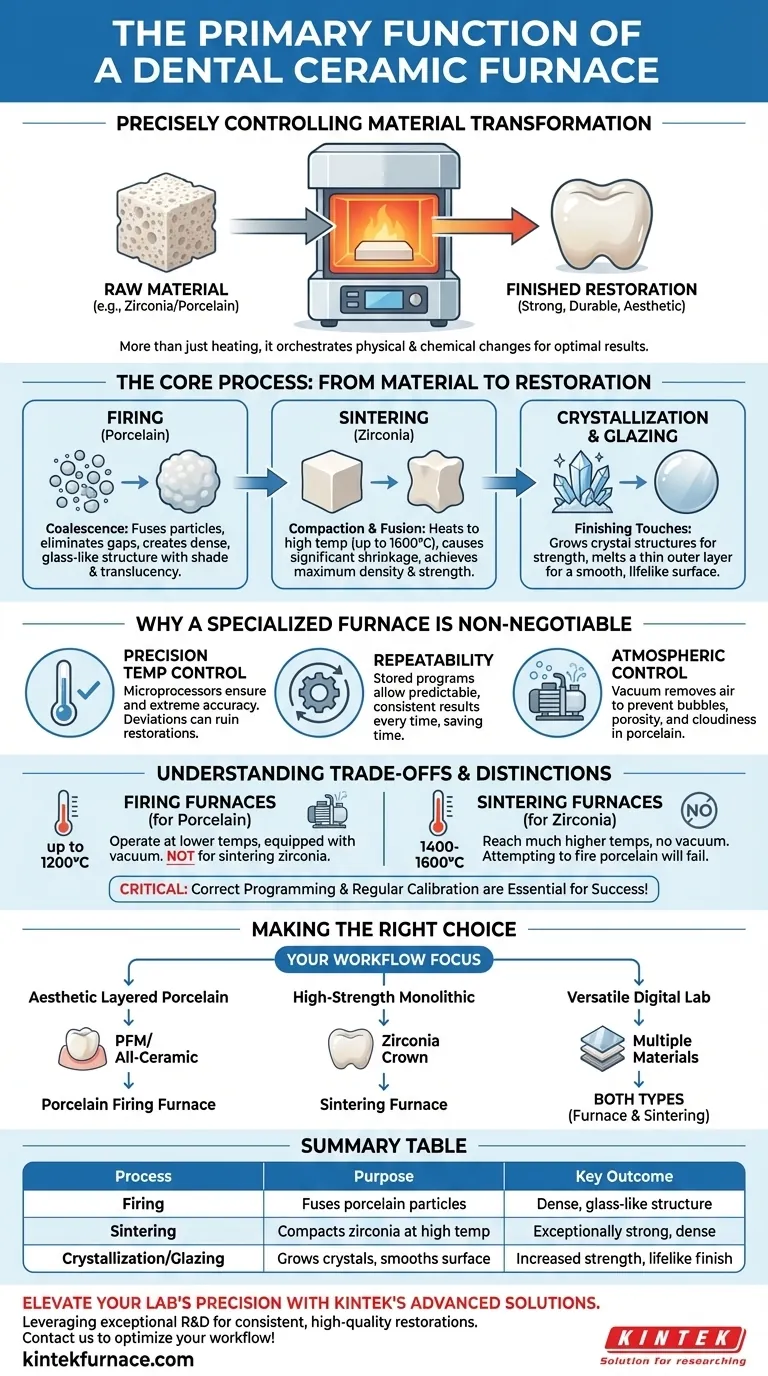

The Core Process: From Material to Restoration

A furnace doesn't just "bake" ceramic; it orchestrates a complex series of events at a microscopic level. The specific process depends on the material being used.

Firing: Creating a Solid Structure

Firing is the classic process used for dental porcelains. It involves heating layers of ceramic powder applied to a core structure.

As the temperature rises, the individual porcelain particles fuse together, a process called coalescence. This eliminates the gaps between particles, creating a dense, solid, glass-like structure with the desired shade and translucency.

Sintering: Achieving Maximum Density

Sintering is primarily used for high-strength ceramics like zirconia, which are often milled in a soft, oversized state using CAD/CAM technology.

The furnace heats the pre-shaped restoration to extremely high temperatures (up to 1600°C). This causes the material to shrink significantly, compact, and fuse into a final, exceptionally dense and strong state. This step is what gives zirconia its renowned durability.

Crystallization & Glazing: The Finishing Touches

Some modern glass-ceramics require a final heating cycle for crystallization. This process grows specific crystal structures within the material, dramatically increasing its strength and achieving its final, natural-looking optical properties.

Nearly all restorations receive a final glaze firing. This is a quick cycle at a specific temperature that melts a thin outer layer, creating a smooth, stain-resistant, and lifelike surface.

Why a Specialized Furnace is Non-Negotiable

You cannot substitute a standard oven for a dental furnace. The quality and safety of a final restoration depend entirely on the furnace's specialized capabilities.

Precision Temperature Control

Every dental ceramic has a unique, manufacturer-specified heating program. A deviation of even a few degrees can ruin a restoration, causing cracks, discoloration, or a poor fit.

Dental furnaces use sophisticated microprocessors to execute these multi-stage programs with extreme accuracy, controlling the rate of temperature increase, hold times, and cooling.

Repeatability and Consistency

A dental laboratory must produce the same high-quality result every single time. Modern furnaces store dozens of programs, allowing technicians to achieve predictable outcomes with the push of a button.

This consistency saves significant time and cost by eliminating the need for adjustments or remakes caused by firing errors.

Atmospheric Control

Many porcelain firing processes require a vacuum. The furnace's vacuum pump removes air from the chamber during heating.

This prevents oxygen from getting trapped, which would otherwise create bubbles, porosity, and a cloudy appearance in the final porcelain restoration.

Understanding the Trade-offs and Distinctions

Not all furnaces are created equal. Using the wrong type of furnace for a given material is a guaranteed path to failure.

Firing Furnaces vs. Sintering Furnaces

These two types of furnaces are not interchangeable. A porcelain firing furnace typically operates up to 1200°C and is equipped with a vacuum pump.

A zirconia sintering furnace must reach much higher temperatures (often 1400°C to 1600°C) but does not require a vacuum. Attempting to sinter zirconia in a porcelain furnace will fail to achieve the required density and strength.

The Importance of Correct Programming

The single most common pitfall is using the wrong program for a specific ceramic. Technicians must precisely match the material being used with the manufacturer-recommended firing or sintering schedule loaded into the furnace.

Maintenance and Calibration

To maintain precision, furnaces require regular calibration. Over time, the temperature sensor (thermocouple) can degrade, causing the actual temperature to drift from the displayed temperature.

Without periodic calibration, a lab will slowly begin producing inconsistent and flawed restorations, leading to costly remakes and a loss of trust from clinicians.

Making the Right Choice for Your Workflow

The type of furnace you need is dictated entirely by the materials you work with.

- If your primary focus is aesthetic layered porcelain (PFM or all-ceramic): Your key need is a porcelain firing furnace with precise temperature ramping and excellent vacuum control.

- If your primary focus is high-strength monolithic restorations: Your essential tool is a high-temperature sintering furnace capable of reaching the required temperatures for zirconia.

- If you operate a versatile digital laboratory: You will almost certainly need both types of furnaces to handle the full range of modern CAD/CAM materials from glass-ceramics to zirconia.

Ultimately, the dental furnace is the cornerstone of quality control in the fabrication of indirect dental restorations.

Summary Table:

| Process | Purpose | Key Outcome |

|---|---|---|

| Firing | Fuses porcelain particles | Dense, glass-like structure with shade and translucency |

| Sintering | Compacts zirconia at high temperatures | Exceptionally strong, dense restoration |

| Crystallization & Glazing | Grows crystals and smooths surface | Increased strength and lifelike finish |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—tailored for dental ceramics like porcelain and zirconia. Our strong deep customization capability ensures we meet your unique experimental needs, delivering consistent, high-quality restorations. Contact us today to discuss how our furnaces can optimize your workflow and enhance your results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations