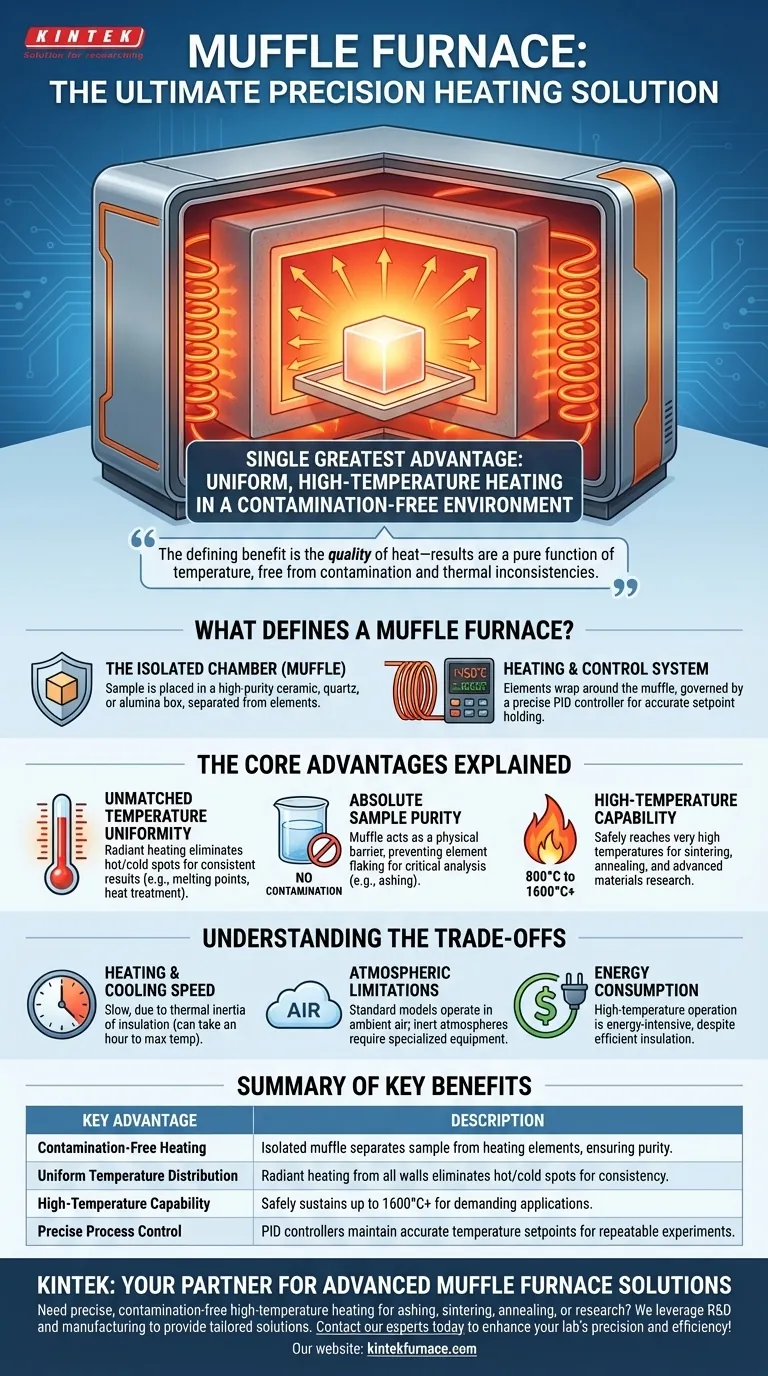

The single greatest advantage of a muffle furnace is its ability to provide extremely uniform, high-temperature heating in a contamination-free environment. This is achieved through its core design feature: an isolated inner chamber (the "muffle") that separates the material being heated from the actual heating elements and any potential environmental impurities. This ensures the integrity of the sample and the repeatability of the process.

While muffle furnaces are valued for reaching high temperatures, their defining benefit is not just heat, but the quality of that heat. The isolated chamber design guarantees that results are a pure function of temperature, free from contamination and thermal inconsistencies.

What Defines a Muffle Furnace?

To understand its advantages, you must first understand its fundamental design. Unlike a simple oven where heating elements may be exposed, a muffle furnace is built around the principle of isolation.

The Isolated Chamber (The "Muffle")

The heart of the furnace is the muffle itself—a box-like chamber typically made of high-purity ceramic, quartz, or alumina.

Your sample is placed inside this chamber. The heating elements are positioned on the outside of the chamber, never touching the sample or its immediate atmosphere.

This design heats the chamber walls, which then radiate heat evenly onto the sample from all directions.

The Heating and Control System

Heating elements made of durable materials like nichrome, silicon carbide (SiC), or molybdenum disilicide (MoSi2) wrap around the muffle.

These elements are governed by a precise temperature controller, typically a PID (Proportional-Integral-Derivative) controller. This system constantly measures the chamber temperature and adjusts power to the elements to hold the setpoint with remarkable accuracy.

The Core Advantages Explained

The unique design of a muffle furnace directly leads to its primary benefits, which are critical for scientific and industrial applications.

Unmatched Temperature Uniformity

Because heat radiates inward from all surfaces of the muffle, it eliminates hot and cold spots. The entire sample experiences the same temperature, which is essential for consistent and accurate results.

This is critical for processes like determining a material's melting point, performing gravimetric analysis, or ensuring a metal part is heat-treated evenly.

Absolute Sample Purity

The muffle acts as a physical barrier between your sample and the heating elements. This is non-negotiable for applications where even trace contamination could ruin the results.

For example, during ashing (burning off organic matter to measure inorganic residue), you need to be certain that the remaining ash is purely from the sample, not from flaking heating elements or other impurities.

High-Temperature Capability

Muffle furnaces are engineered to safely reach and sustain very high temperatures, often ranging from 800°C to 1600°C (1472°F to 2912°F) or even higher in specialized models.

This capability makes them indispensable for sintering ceramics, annealing metals, and conducting advanced materials research that is impossible in standard laboratory ovens.

Understanding the Trade-offs

No tool is perfect for every job. Being objective means acknowledging the inherent limitations of a muffle furnace.

Heating and Cooling Speed

The same insulated thermal mass that provides excellent temperature uniformity also creates thermal inertia. Muffle furnaces do not heat or cool instantly.

A typical furnace can take an hour or more to reach its maximum temperature. This is significantly slower than direct-heating methods or specialized equipment like microwave furnaces.

Atmospheric Limitations

A standard muffle furnace operates in ambient air. While it prevents contamination from the furnace components, it does not control the atmosphere itself.

If your process requires an inert atmosphere (like nitrogen or argon) or a reactive one, you will need a more complex and expensive furnace with gas-purging capabilities.

Energy Consumption

Reaching and maintaining temperatures over 1000°C is an energy-intensive process. While modern furnaces use high-grade insulation like ceramic fiber to maximize thermal efficiency, they remain significant power consumers, especially during long runs.

Is a Muffle Furnace Right for Your Application?

Choosing the right heating instrument depends entirely on your primary goal. Use this guide to make an informed decision.

- If your primary focus is analytical precision (ashing, moisture/volatile matter determination): The muffle furnace is the correct choice. Its temperature uniformity and contamination control are essential for repeatable, accurate results.

- If your primary focus is heat treating, sintering, or annealing materials in air: This is the core industrial and research function of a muffle furnace, making it the ideal tool.

- If your primary focus is maximum speed and sample throughput: You may want to evaluate alternatives like a microwave muffle furnace, which can offer dramatically faster heating cycles for certain materials.

Ultimately, a muffle furnace is the definitive tool when the purity of your sample and the precision of your thermal process cannot be compromised.

Summary Table:

| Key Advantage | Description |

|---|---|

| Contamination-Free Heating | Isolated muffle chamber separates sample from heating elements, ensuring sample purity. |

| Uniform Temperature Distribution | Radiant heating from all chamber walls eliminates hot/cold spots for consistent results. |

| High-Temperature Capability | Safely reaches and sustains temperatures up to 1600°C+ for demanding applications. |

| Precise Process Control | PID controllers maintain accurate temperature setpoints for repeatable experiments. |

Need precise, contamination-free high-temperature heating for your lab? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced muffle furnace solutions tailored to your unique requirements. Whether you're performing ashing, sintering, annealing, or advanced materials research, our deep customization capabilities ensure your furnace delivers the uniformity and purity your work demands.

Contact our experts today to discuss how a KINTEK muffle furnace can enhance your laboratory's precision and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment