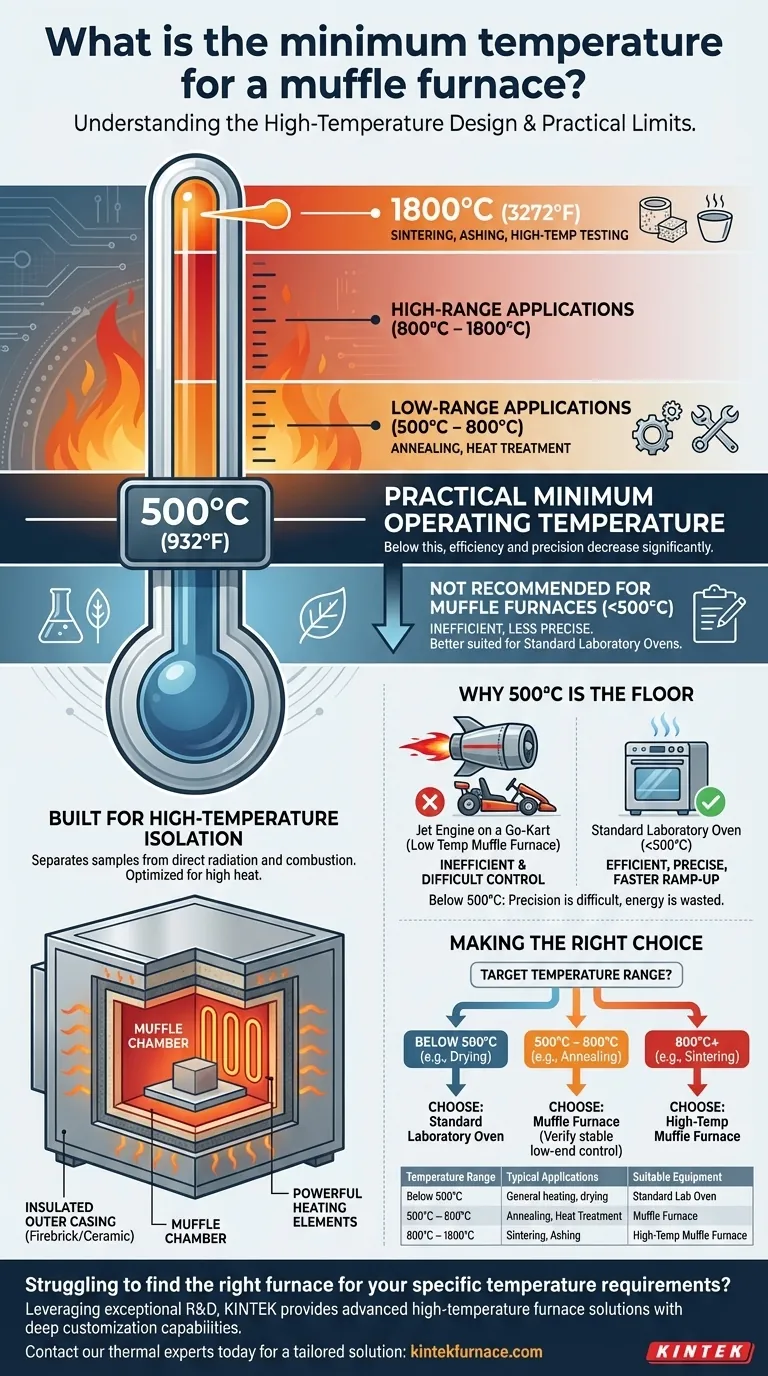

While known for extreme heat, a muffle furnace is not designed for low-temperature applications. Based on its construction and intended use, the practical minimum operating temperature for most models is approximately 500°C (932°F). Below this, the furnace becomes inefficient and less precise compared to other types of laboratory ovens.

A muffle furnace is fundamentally a high-temperature tool. The real question is not its absolute minimum temperature, but rather its effective operating range, which typically begins at 500°C for processes like annealing and extends up to 1800°C for sintering.

Understanding the Muffle Furnace's Design Purpose

Built for High-Temperature Isolation

A muffle furnace is defined by its "muffle"—an insulated outer casing, often made of firebrick or ceramic, that separates the heating elements from the internal chamber.

This design protects the sample from direct radiation and combustion byproducts, but it is optimized for reaching and maintaining very high temperatures efficiently.

The Typical Operating Range

The general working range for muffle furnaces spans from 500°C to 1800°C. This wide range is not a feature of a single furnace but reflects the capabilities of different models designed for specific tasks.

Why 500°C is the Practical Minimum

The powerful heating elements and heavy insulation are engineered to manage extreme heat. At temperatures below 500°C, these components make precise control difficult and waste significant energy, much like using a jet engine to power a go-kart.

How Temperature Range Dictates Application

Low-Range Applications (500°C – 800°C)

This lower end of the muffle furnace's capability is primarily used for material science processes that do not require melting.

Common applications in this range include annealing, which alters a material's microstructure to make it more workable, and certain heat treatment procedures.

High-Range Applications (800°C – 1800°C)

This is the domain where muffle furnaces excel. These temperatures are used for tasks like high-temperature sintering of ceramics, ashing samples to determine inorganic content, and other advanced materials testing.

Model-Specific Temperature Ceilings

The maximum temperature is determined by the furnace type and its construction.

- Box-type furnaces typically operate up to 1200°C.

- Tube-type furnaces can often reach 1500°C.

- High-temperature and vacuum models are designed to exceed 1500°C, with some reaching 1800°C or more.

Understanding the Trade-offs and Limitations

Inefficiency at Low Temperatures

Using a muffle furnace for a process requiring 200°C is technically possible but highly impractical. A standard laboratory oven would reach and hold that temperature faster, with greater stability, and using far less energy.

Ramp-Up Time and Control

Muffle furnaces require significant time—often an hour or more—to safely reach their target temperature. The process involves gradually increasing voltage to protect the heating elements, which makes fine-tuning at lower temperatures a cumbersome task.

Risk of Misuse

Attempting to force a furnace beyond its rated maximum can destroy the heating elements. Conversely, constant low-temperature operation can be inefficient and may not be what the controller is optimized for, leading to temperature overshooting.

Making the Right Choice for Your Process

Choosing the correct thermal equipment depends entirely on your target temperature range.

- If your primary focus is on processes below 500°C: A standard laboratory oven is the more efficient, precise, and cost-effective choice.

- If your primary focus is on annealing or heat treatment (500°C - 800°C): A muffle furnace is suitable, but confirm that your chosen model provides stable control in its lower operational range.

- If your primary focus is on sintering, ashing, or other high-heat tasks (800°C+): The muffle furnace is the correct tool, and your selection should be based on the maximum temperature your process requires.

Ultimately, selecting the right furnace is about matching the tool's capabilities to your specific thermal processing needs.

Summary Table:

| Temperature Range | Typical Applications | Suitable Equipment |

|---|---|---|

| Below 500°C | General heating, drying | Standard Laboratory Oven |

| 500°C – 800°C | Annealing, Heat Treatment | Muffle Furnace |

| 800°C – 1800°C | Sintering, Ashing | High-Temp Muffle Furnace |

Struggling to find the right furnace for your specific temperature requirements?

At KINTEK, we understand that precise thermal processing is critical to your research and production outcomes. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need a standard muffle furnace for annealing or a custom high-temperature solution for sintering, our experts can help you select or design the perfect equipment. Contact our thermal experts today to discuss your application and get a tailored solution that ensures efficiency, precision, and reliability.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production