At its core, atmosphere control during heat treating serves one primary purpose: to protect the metal component's surface from undesirable chemical reactions with the surrounding air at high temperatures. This is critical for preventing common defects like scaling (oxidation) and ensuring the part's intended surface chemistry and metallurgical properties are achieved.

While preventing visible scaling is the most obvious benefit, the true purpose is to ensure the final component meets its specified metallurgical properties. Precise atmosphere control is the mechanism that guarantees consistent surface chemistry, prevents hidden defects, and ultimately delivers a functional and reliable part.

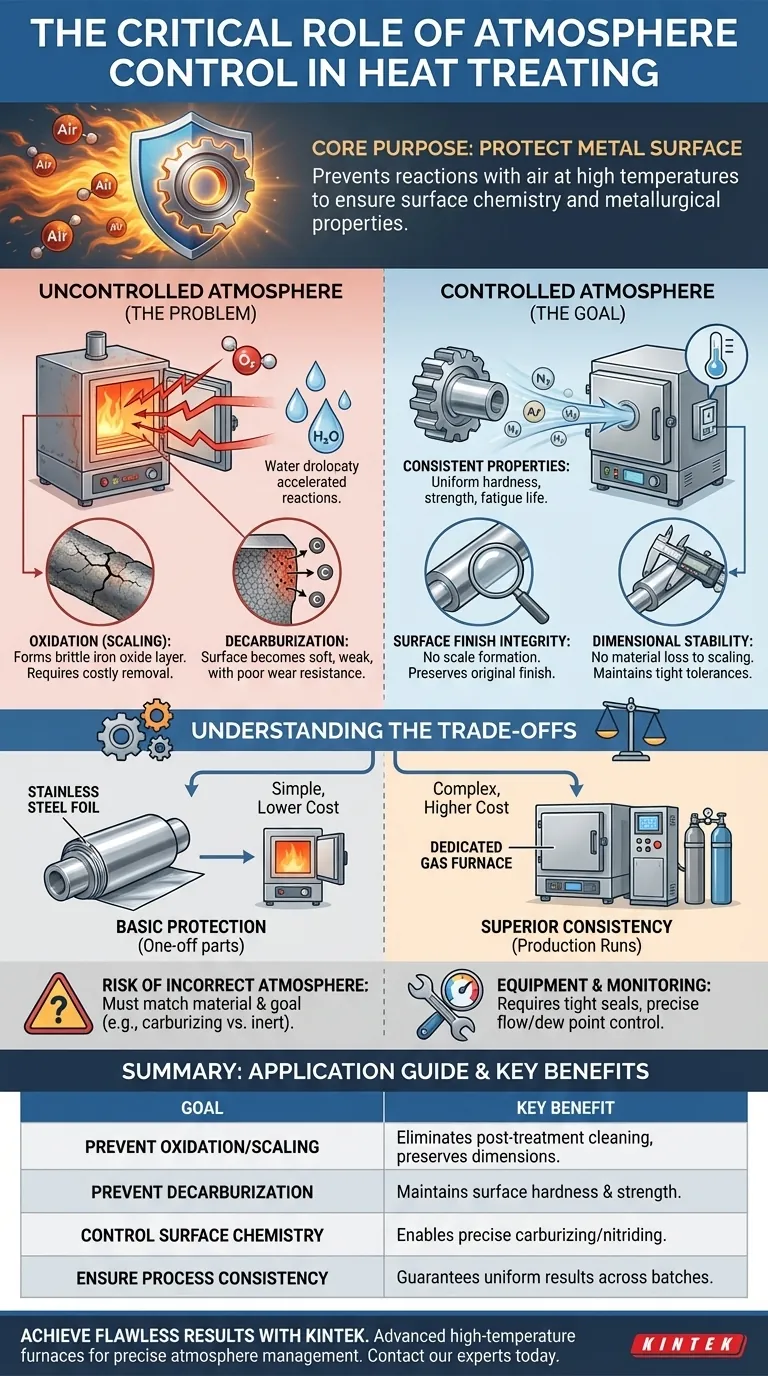

Why Uncontrolled Atmospheres Are a Problem

Heating metals to the high temperatures required for austenitizing—often exceeding 1500°F (815°C)—makes them highly reactive. Exposing them to ambient air during this process leads to significant and often irreversible damage.

The Threat of Oxidation (Scaling)

When hot steel is exposed to oxygen, a chemical reaction occurs that forms a thick, brittle layer of iron oxide on the surface. This is known as scale.

This scale layer is detrimental because it must be removed through costly secondary operations like sandblasting or grinding, and it can alter the final dimensions of the part.

The Degradation of Surface Chemistry

Beyond visible scaling, uncontrolled atmospheres can alter the chemical makeup of the steel's surface. The most common issue is decarburization, where carbon atoms diffuse out of the surface layer.

Since carbon is the primary element that gives steel its hardness, a decarburized surface is soft, weak, and has poor wear resistance, rendering the heat treatment ineffective for that portion of the material.

The Role of Moisture

Even trace amounts of moisture (water vapor) in the air or in the furnace atmosphere dramatically accelerate these negative reactions.

Moisture increases oxygen's reactivity, making it much harder to achieve a clean, defect-free surface. This is why advanced systems monitor and control the dew point—a measure of moisture content—to ensure the protective gas is sufficiently dry.

The Goals of Precise Atmosphere Control

By replacing the reactive air in a furnace with a carefully managed atmosphere, you gain direct control over the outcome of the heat treatment process. This is typically done in a tightly sealed furnace using inert or specific reactive gases.

Ensuring Consistent Metallurgical Properties

The primary goal is to protect the surface chemistry so the component achieves its target hardness, strength, and fatigue life uniformly.

By preventing decarburization, atmosphere control ensures the properties engineered into the alloy are present at the surface, where stresses are often highest.

Maintaining Surface Finish and Integrity

A controlled atmosphere prevents the formation of scale, preserving the part's original surface finish.

This eliminates the need for aggressive post-treatment cleaning, saving time and money while preventing potential damage to the component.

Guaranteeing Dimensional Stability

Because no material is lost to heavy scaling, the component's dimensions remain stable and within their specified tolerances. This is critical for precision parts that must fit and function within a larger assembly.

Understanding the Trade-offs

Choosing and implementing atmosphere control involves balancing protection, complexity, and cost. There is no single solution that fits every application.

Method Complexity vs. Cost

For small-scale or non-critical applications, simple methods like wrapping a part in stainless steel foil can provide adequate protection by trapping a small amount of air, which is quickly consumed, leaving a mostly inert environment.

For high-volume production or critical components, a dedicated furnace with a continuous flow of a protective gas like nitrogen, argon, or hydrogen is necessary. These systems offer superior control but come with higher equipment and operational costs.

The Risk of an Incorrect Atmosphere

Simply having an atmosphere is not enough; it must be the correct one for the material and the desired outcome.

An atmosphere that is accidentally carburizing can make a low-carbon steel part brittle. Conversely, an atmosphere that is unintentionally oxidizing, even slightly, can ruin an entire batch of high-precision components.

Equipment and Monitoring Demands

Effective atmosphere control relies on equipment integrity. A furnace must be tightly sealed to prevent air from leaking in and contaminating the protective gas.

Furthermore, it requires precise monitoring of gas flow rates, pressure, and dew point to ensure the environment inside the furnace remains consistent throughout the entire heating and cooling cycle.

How to Apply This to Your Project

Your choice of atmosphere control should be dictated by your end goal and the scale of your operation.

- If your primary focus is basic protection for one-off tool steel parts: A simple stainless steel foil wrap is often a sufficient and cost-effective method to prevent major scaling and decarburization.

- If your primary focus is achieving a superior surface finish and high consistency across a production run: A furnace with a controlled inert gas atmosphere, like dry nitrogen, is essential for reliable results.

- If your primary focus is intentionally altering the surface chemistry (e.g., carburizing or nitriding): You require a specialized furnace with a reactive gas atmosphere and precise control over its chemical potential.

Ultimately, mastering atmosphere control is fundamental to ensuring the final quality, reliability, and performance of your heat-treated components.

Summary Table:

| Goal of Atmosphere Control | Key Benefit |

|---|---|

| Prevent Oxidation/Scaling | Eliminates costly post-treatment cleaning and preserves dimensions. |

| Prevent Decarburization | Maintains surface hardness and strength for part reliability. |

| Control Surface Chemistry | Enables precise carburizing or nitriding for specific properties. |

| Ensure Process Consistency | Guarantees uniform results across production batches. |

Achieve Flawless Heat Treatment Results with KINTEK

Mastering atmosphere control is critical for part performance, but it requires the right equipment. KINTEK’s advanced high-temperature furnaces are engineered for precise atmosphere management, ensuring your components achieve their intended metallurgical properties batch after batch.

Our solutions are ideal for manufacturers who need:

- Superior Surface Finish: Prevent scaling and decarburization to eliminate secondary operations.

- Dimensional Stability: Protect part tolerances by avoiding material loss.

- Process Consistency: Rely on tight seals and precise gas control for repeatable results.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capability to precisely meet your unique thermal processing requirements.

Ready to eliminate heat treatment defects and guarantee part reliability? Contact our experts today to discuss your application and discover the perfect furnace solution for your needs.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the main types of nitrogen-based furnace atmospheres? Optimize Your Heat Treatment Process

- What role does a high-temperature activation furnace perform in magnetic catalyst synthesis? Optimize Your Fe3O4 Yield

- What is a retort furnace and what are its key features? Discover Precision Heating for Superior Material Processing

- What are some of the reasons why a controlled atmosphere furnace is desirable in sintering? Achieve Superior Material Integrity

- What are the common industrial processes performed using an atmosphere box furnace? Discover Key Applications for Material Processing

- What energy-saving and environmental benefits do box type atmosphere furnaces provide? Boost Efficiency and Cut Waste

- Why is an argon atmosphere used? Ensure Material Purity in High-Temp Processes

- What factors should be considered when purchasing an inert oven? Ensure Optimal Performance and Safety